Commissioning of the second SFM line in Russia for the production of cast iron pipeline valves at Joint Stock Company "Foundry and Mechanical Plant" in Semenov

The project started on 16.12.2025

OJSC "Foundry and Mechanical Plant" (OJSC "LMZ") is one of the leading manufacturers of pipeline valves in the Russian Federation. Its main areas of activity are: parallel cast iron gate valves, cast iron gate valves with rubberised wedges, steel wedge gate valves, cast iron rotary disc valves, cast iron flanged magnetic and sediment filters.

The plant’s products are widely used in housing and communal services, water supply and sewerage systems, heating networks, and the oil and gas industry.

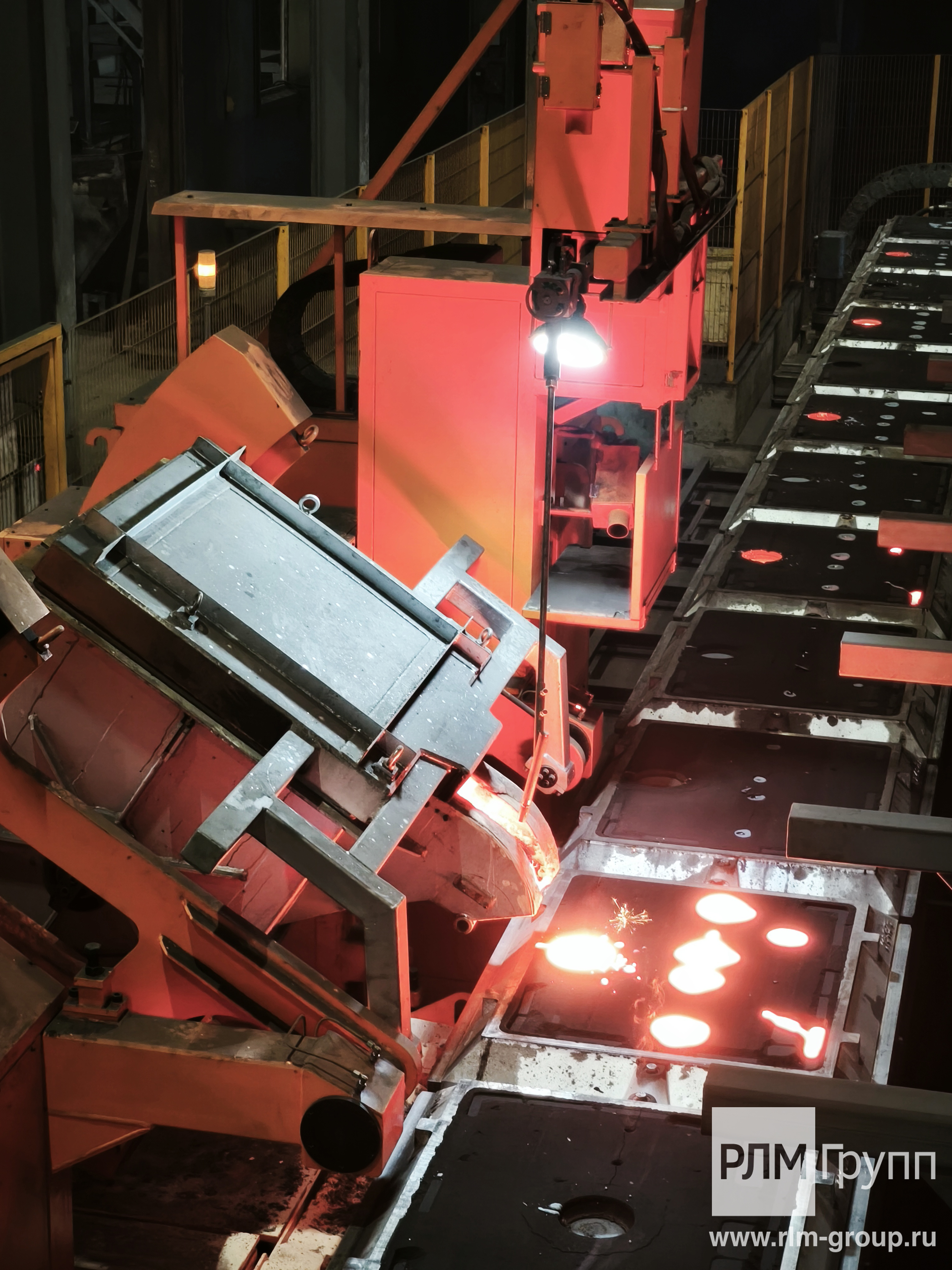

In December 2025, an automatic green sand moulding line produced by SUZHOU FOUNDRY MACHINERY (SFM) was launched.

Main characteristics of the moulding line:

- Mould size: 1,000×800×350/350 mm;

- Mould compaction method: combined squeezing from top and bottom;

- Productivity: 50 full moulds per hour;

- Cooling time: 89 minutes;

- Drive type: hydraulic pushers for horizontal and vertical movement of moulds in the line.

- Mould pouring is carried out by a one-position PU pouring machine with unheated ladles;

- The scope of supply includes hydraulic, electrical and pneumatic systems, a shake-out grid, trolleys and moulds.

One of the features of this project is that the entire complex was installed and commissioning in a short 3 months from the date of delivery of the equipment to Semenov, thanks to the coordinated work of the supplier and customer teams.

The commissioning of the automatic moulding line helped to JSC "LMZ" to improve key technical and economic indicators by reduction of the human factor and stabilising technological cycles, production new types of products, reducing the level of scrap castings, and increasing the dimensional accuracy and surface of castings.