Technological support

Our company has been cooperating with different foundries for more than 10 years and provides technological support during the implementation and service of technological equipment, during testing and application of materials. Also the company develops new and optimizes function processes in order to reduce the production cost of castings, increase yield ratio, improvements of quality.

The presence of highly qualified technical specialists in the staff allows you to perform these tasks. The company also cooperates with 2 metallurgical laboratories: in Nizhny Tagil and Voronezh (t-center.vrn.ru).

For our customers we offer the following services:

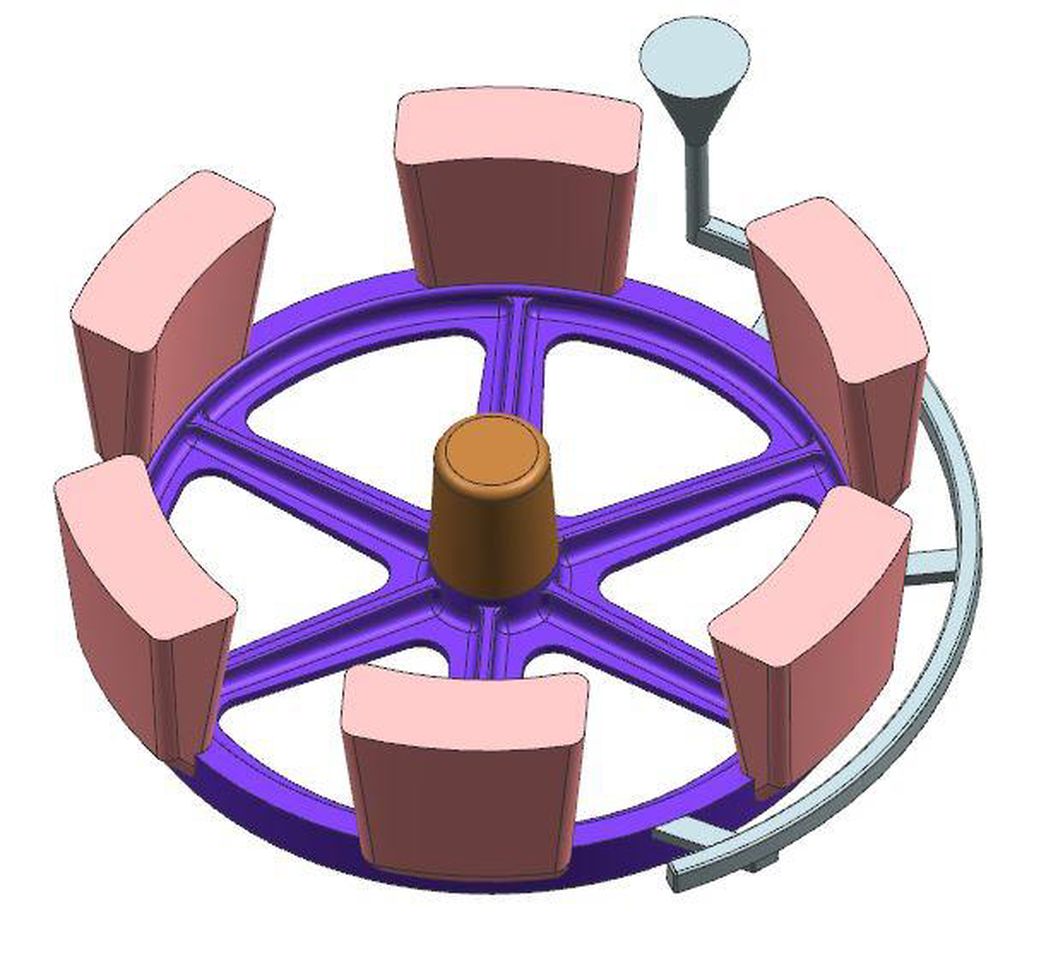

1. Development/optimization of casting technology

It includes: the choice of location of the casting in the mold, the choice of the gate system, the choice of materials for the production of molds and cores, the choice of gating system, the choice of coatings, recommendations for purification and modification, etc.

2. Выбор оптимальных режимов работы технологического оборудования

It includes: recommendations for binders settings, setting mold holding time, mold destruction time, etc. It is possible to connect to equipment and configure.

3. The choice of optimal parameters of the materials

It includes: selection of coating parameters for the method of their application, selection of size and composition of exothermic sleeves, etc.

4. Testing of materials in foundry

It includes: recommendations on the use of materials, participating in tests of a company specialist in order to control the quality of the materials and the quality of castings.

5. Training of personnel

Trainings of personnel can be carried out: after the commissioning of technological equipment for get acquainted with the capabilities of the equipment, its adjustment and repair, or during application of new materials — to teach employees with the features of the new material, issuing of recommendations how to use these materials.

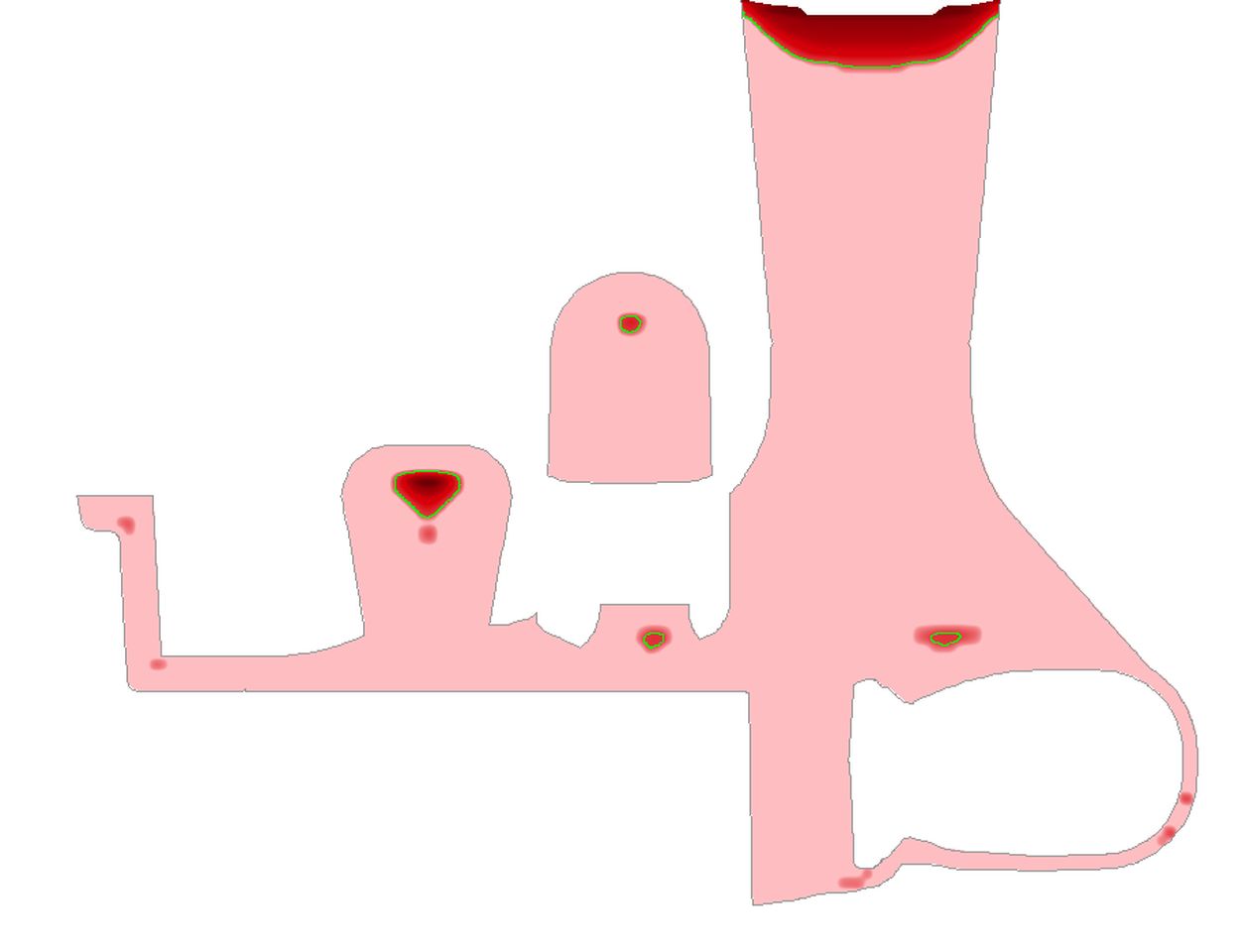

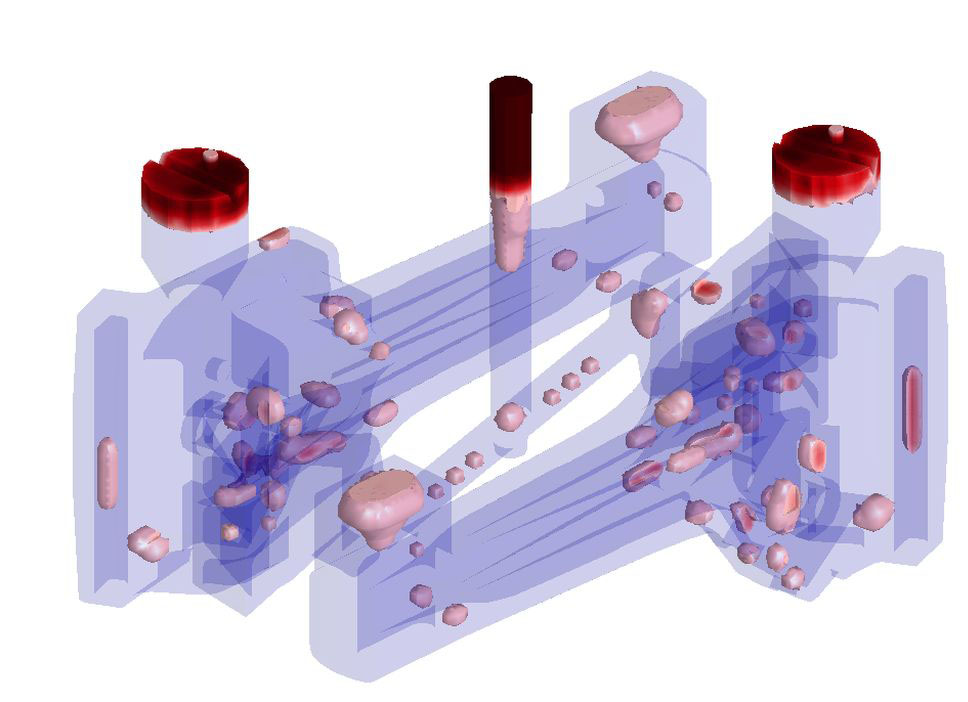

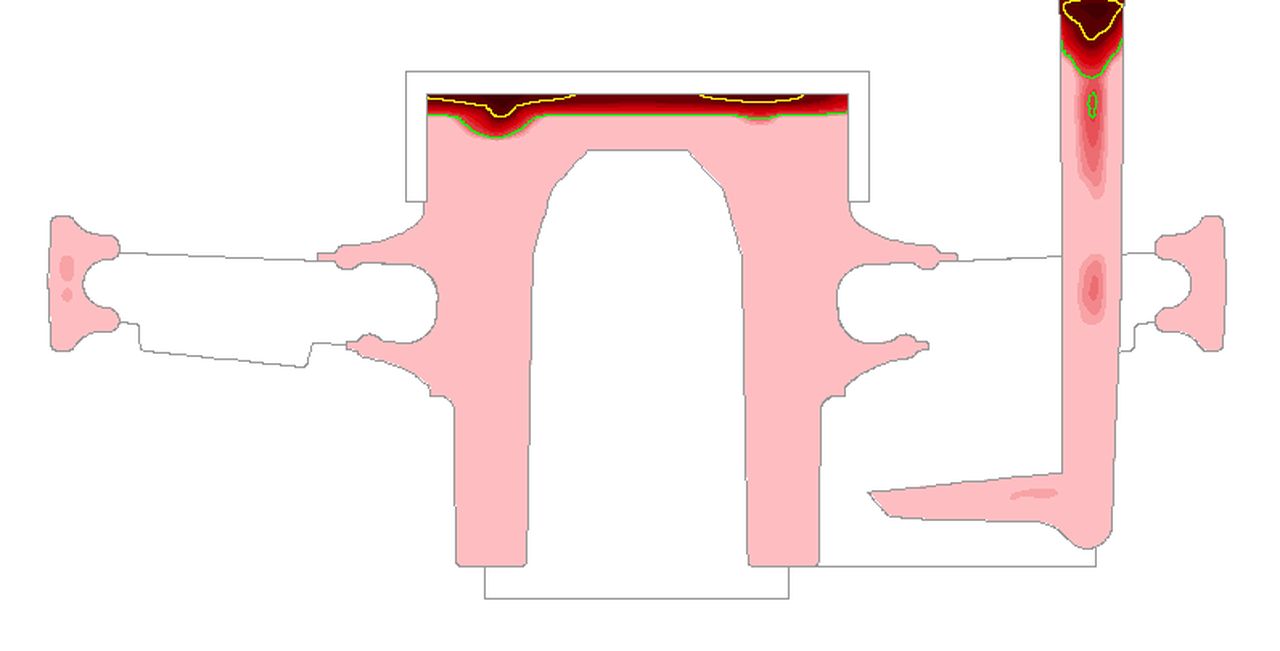

6. Computer simulation of casting

It includes complex modeling with the aim of testing casting technology or partial modeling with the aim of selecting exothermic sleeves, gating system, etc. For this, modern computer software are used.