Engineering

RLM Group LLC together with its partners performs basic engineering, which is often a necessary stage in the building of a new foundry or reconstruction of an existing one. The target of basic engineering is to confirm the initial data, choice of technological solutions, definition of CAPEX, definition of scope of necessary equipment and works, adapt the project to the customer’s site. The implementation of this work helps the customer to evaluate all the volumes of the project, as well as to assess the costs of project realization. After completing of basic engineering, the further works detailed engineering and working documentation is simplified, and the cost of concluding contracts for equipment becomes more attractive. The timing for basic engineering depends on the complexity of the work and the necessary detailed study.

Scope of basic engineering includes:

- Analysis of the nomenclature, choice and justification of technology

- Organization of foundry processes and selection of equipment:

- Preparation and handling of the scrap

- Melting

- Core making/core handling/core storage/core delivery/core setting

- Mold sand preparation and handling

- Mould making

- Pouring

- In mould cooling of castings

- Casting extraction/shake-out, handling, cooling

- Shot blasting

- Heat treatment

- Finishing, marking, inspecting, palletizing, shipping

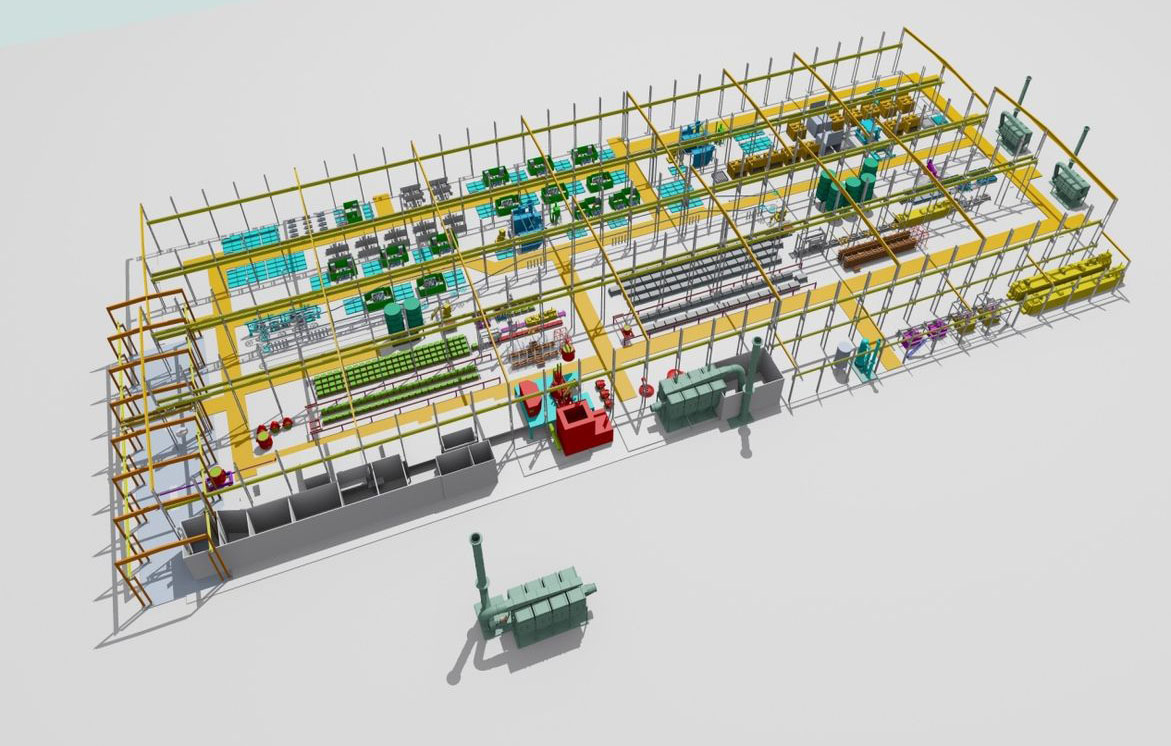

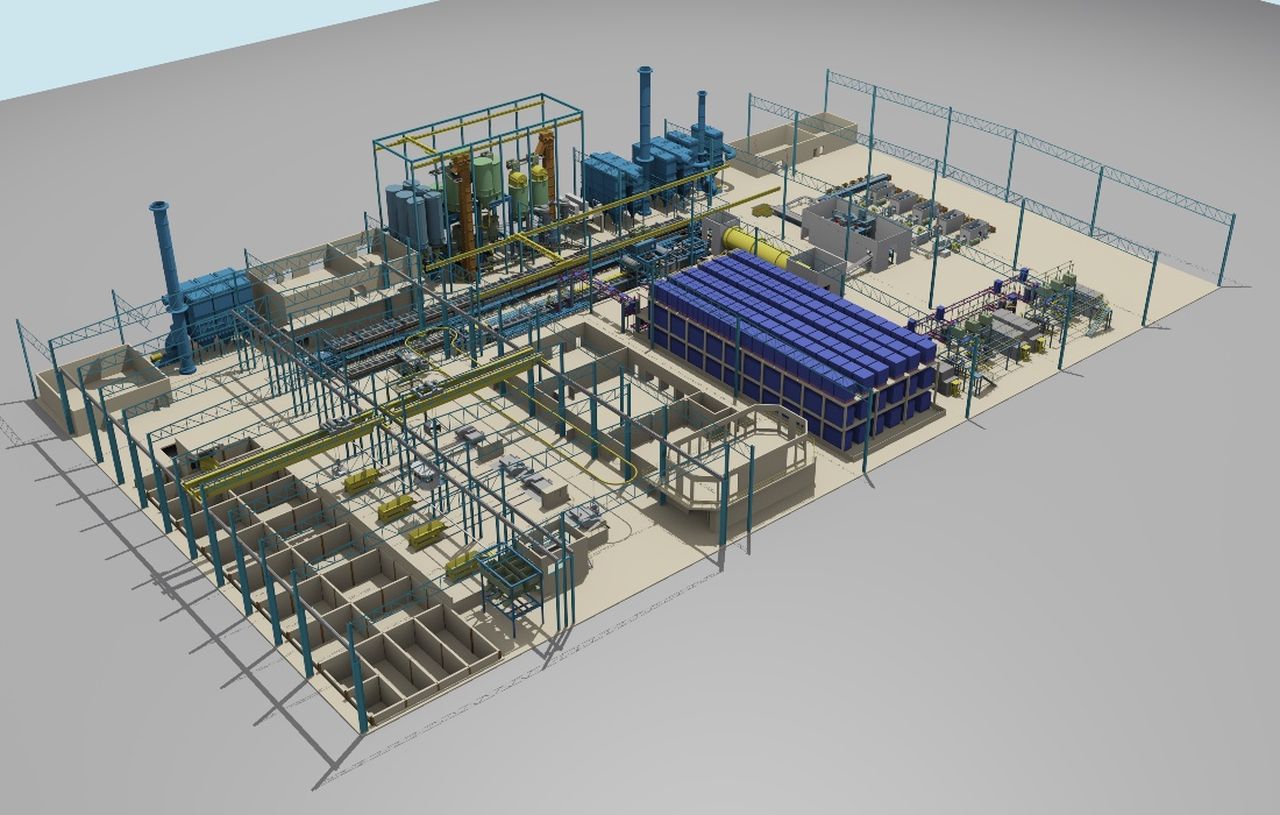

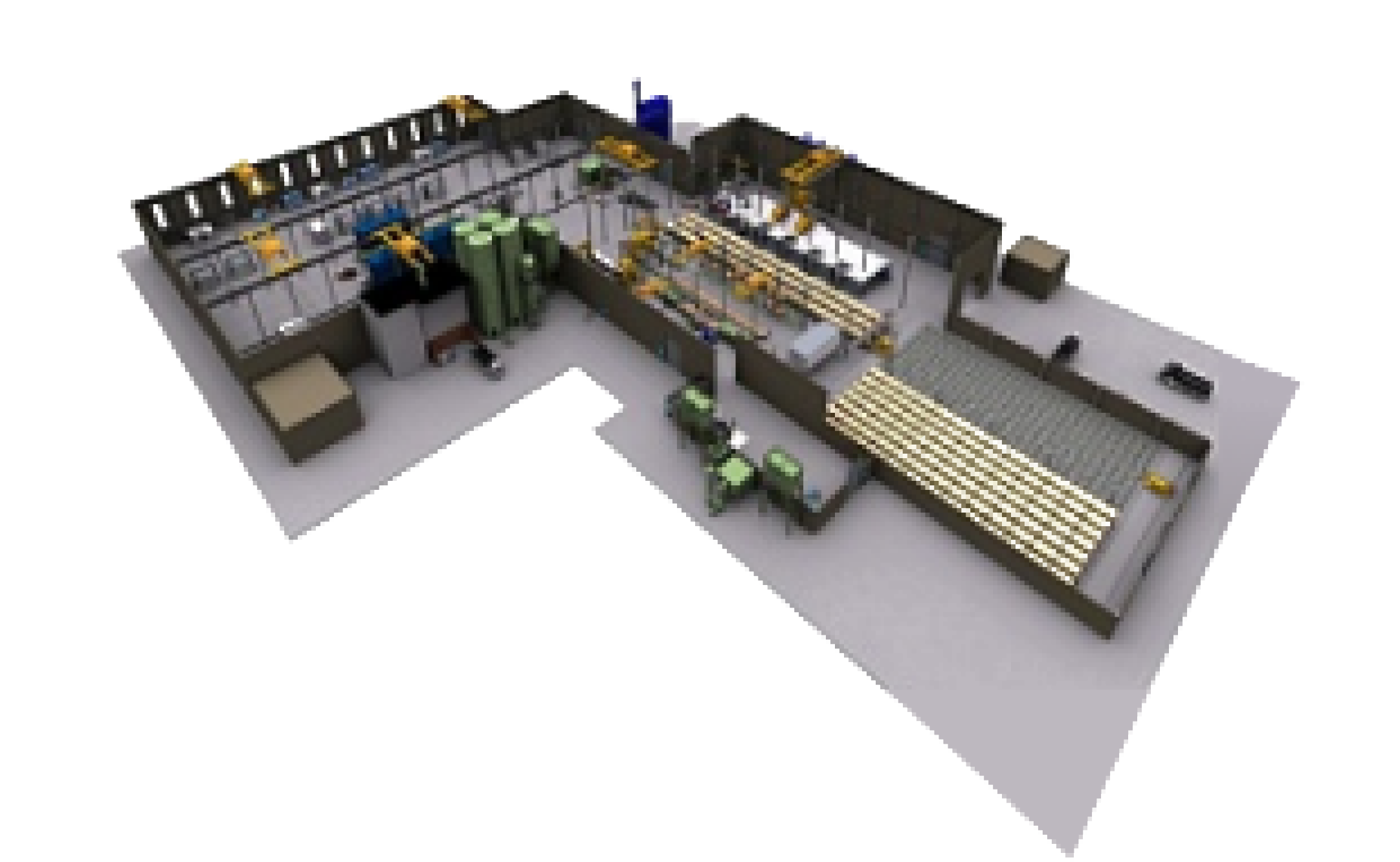

- Facility concept layout / elevation in AutoCAD format

- Mechanized consideration for mould handling and casting finishing

- Capital Cost estimates (CAPEX)

- Utilities consumption

- Environmental consideration

- Implementation and investment phasing plan

- Workforce schedule

- Raw material consumption

- Schedule of implementation

- Financial Feasibility

- Product cost

- Financial ratios (IRR, NPV, payback, etc.)

- Sensitivity analysis

- Cash flow

- P&L and Balance Sheets

- Debit-equity Structure