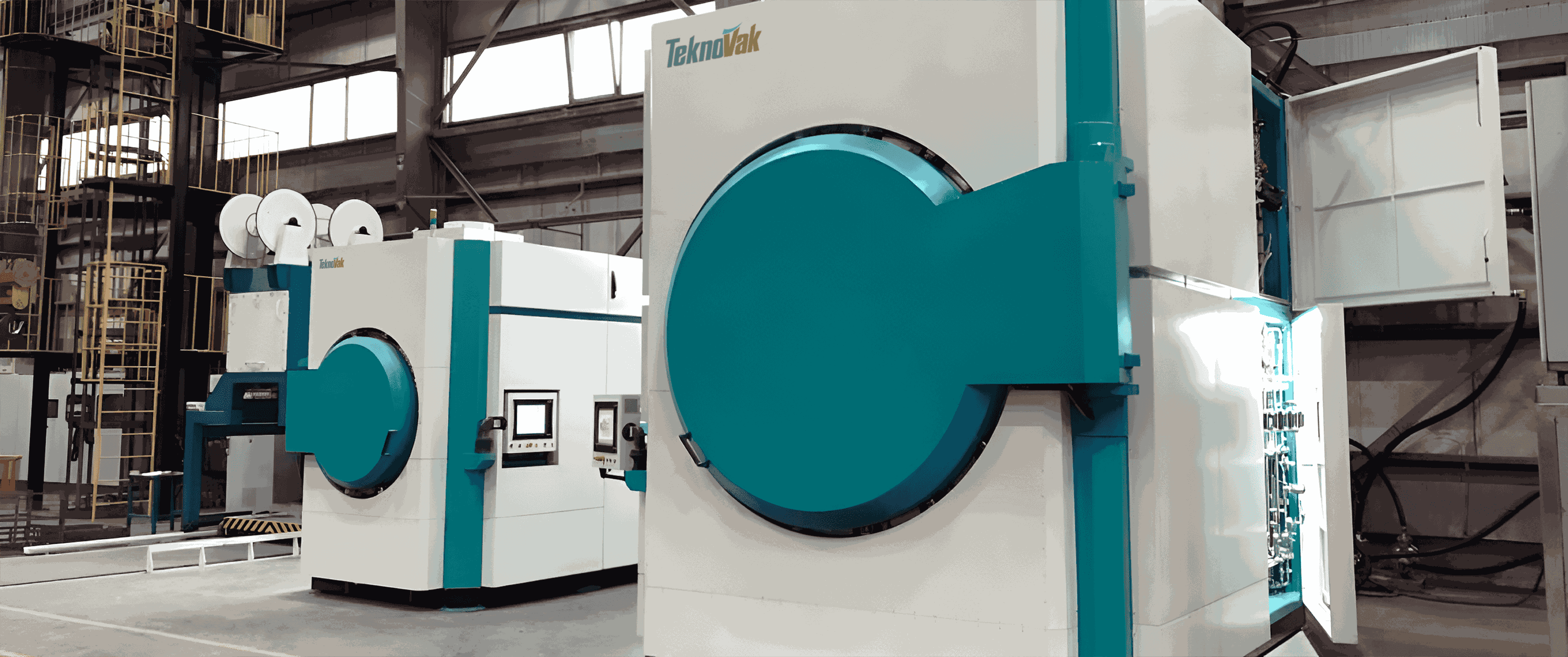

TeknoVak

Equipment for carburization, quenching (salt/oil)

The TEKNOVAK company (Turkey) has been producing equipment for thermal/chemical-thermal processing of various parts for mechanical engineering, aviation and other industries for more than 30 years:

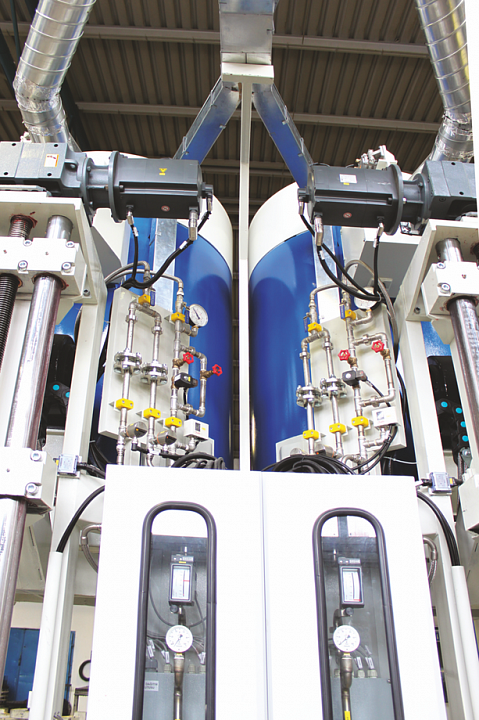

1) Modular lines based on bell furnaces (hardening, tempering) for quenching (salt/oil/water), carburization in a protective atmosphere. The entire heat treatment process is carried out in a protective atmosphere, and the transfer of charge into the quenching environment occurs in a protective atmosphere, excluding contact with air. Auxiliary equipment: Washing machines, salt regeneration systems, robotic systems for loading/unloading cages, baskets, etc.

Advantages:

- Modular system for several processes in different gas environments;

- No vibration when moving the furnace with charge on rollers;

- Salt, oil, water and various quenching media;

- Short time for transferring the charge into the quenching tank (less than 15 seconds);

- Possibility of increasing productivity in the same line by adding furnaces and quenching tanks;

- To minimize deformation problems through intermittent hardening;

- No loss of heat and atmosphere during transfer of the charge to the quenching tank;

- Control of carbon potential by oxygen and hydrogen sensors;

- Correct process control using STANGE-Corbo-O/S software;

- Rapid decrease in temperature during carburization to the quenching temperature;

- Reproducible and sustainable technological capabilities.

2) Innovative furnaces for nitriding with the ability to regulate the nitrogen potential (KN) in horizontal and vertical versions.

Advantages:

In innovative TEKNOVAK nitriding furnaces, the entire CHT (Chemical Heat Treatment) process, for example, for an extrusion die for aluminum parts, takes only 4 hours.

The world’s only patented technology.

3) Furnaces for heat treatment of aluminum process T6.

4) Cryogenic chambers for the aviation and automotive industries.