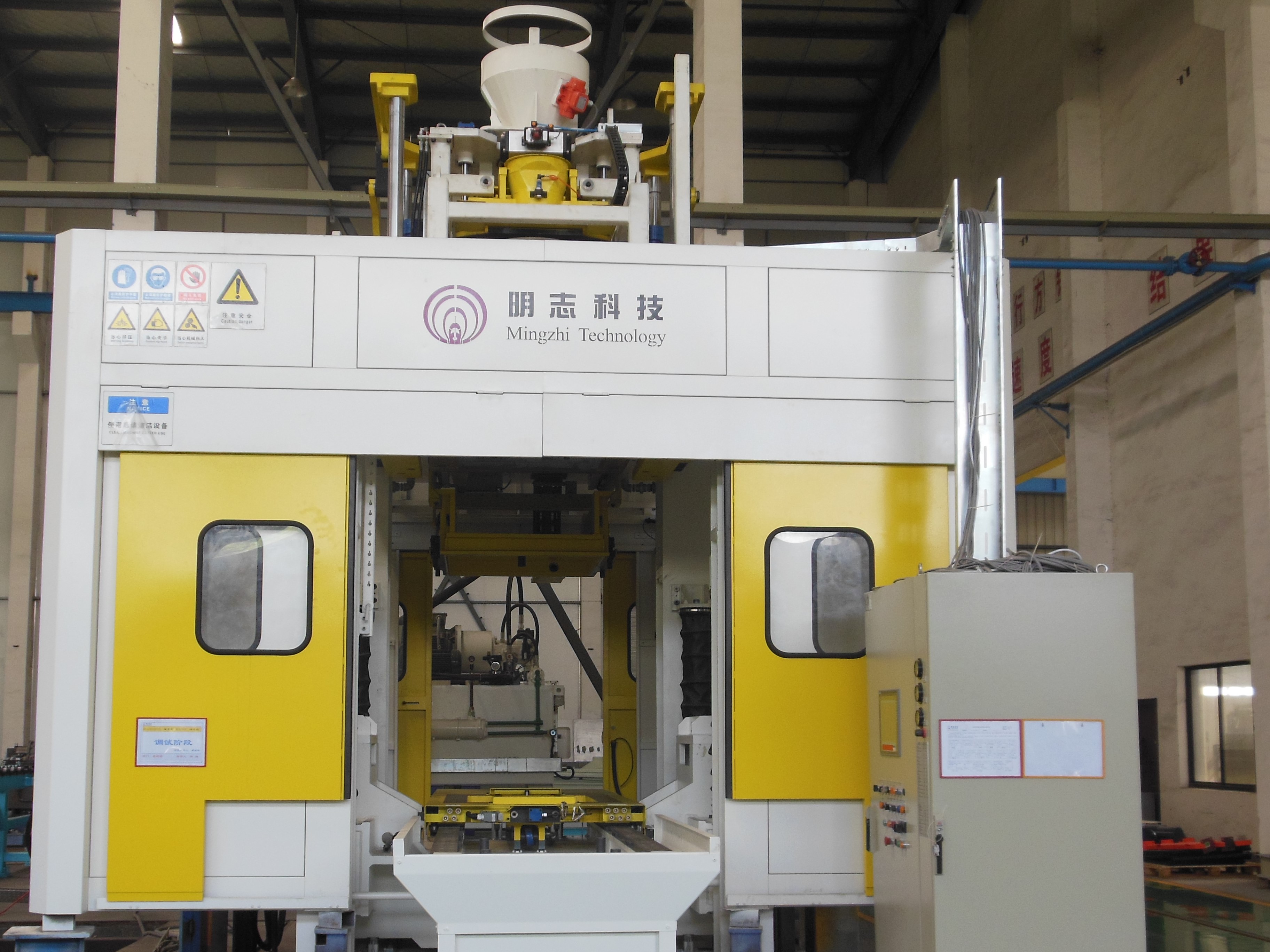

MINGZHI TECHNOLOGY

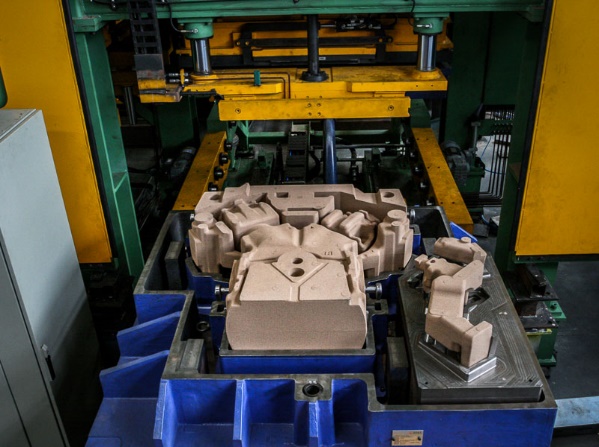

Core shooter machines, tooling

Mingzhi Technology’s roots date back to 1999, with the founding of the Suzhou-Laempe Foundry equipment company. Reestablished as Suzhou Mingzhi Technology Ltd. in 2003, today we have over 700 dedicated employees spread over two divisions: Mingzhi Technology Equipment and Mingzhi Technology Castings.

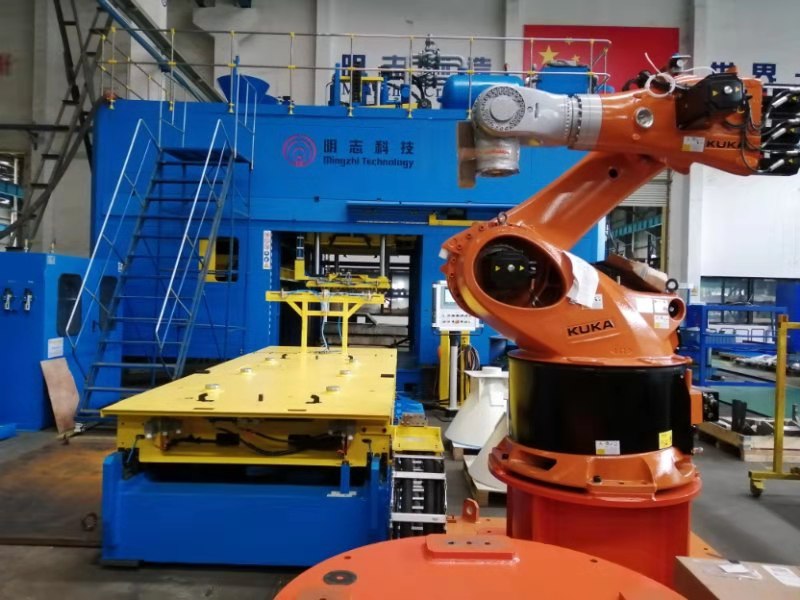

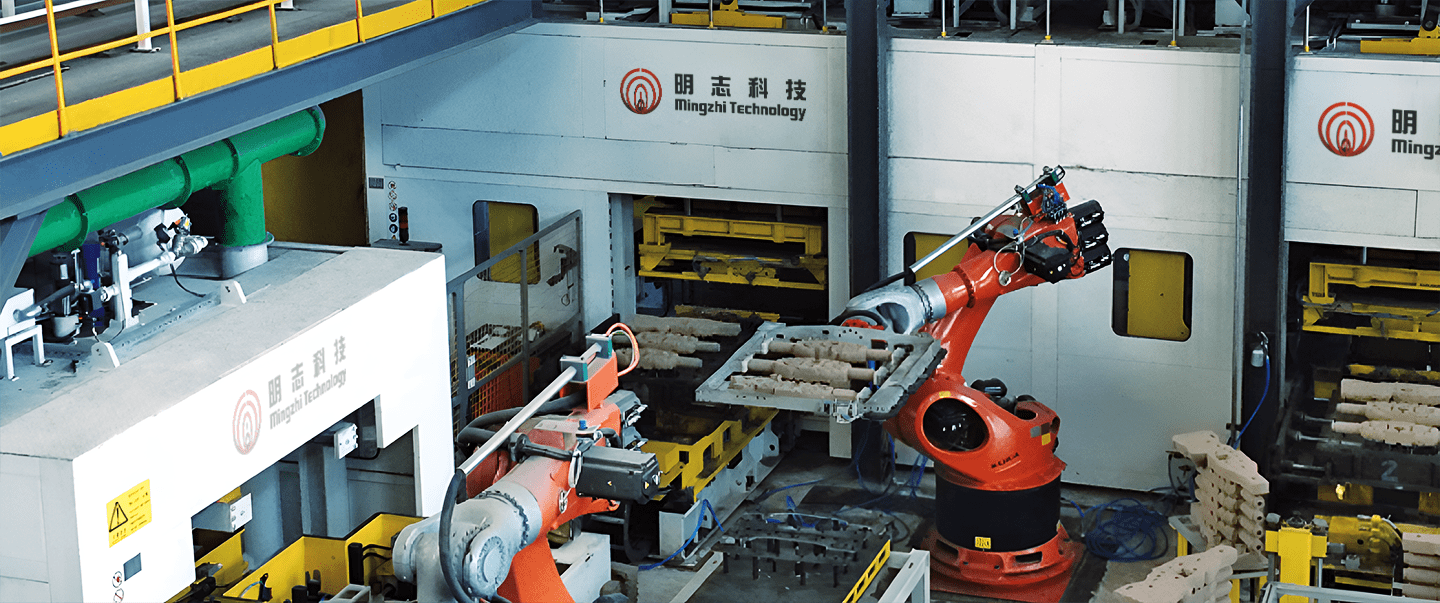

Mingzhi Technology’s Equipment Division is now a world-class producer of high-end core shop equipment. From our facilitie in Europe, we design, develop and produce core shop solutions that include a wide range of core shooters for various processes, sand preparation equipment, gassing units, core handling equipment, core package solutions using sand-precision casting technology, core-boxes and tooling. We engineer comprehensive proposals to meet unique core production requirements for customers worldwide.

Introducing our European operations in Leipzig, Germany

Through the full acquisition of the former DisaIndustrieanglagen GmbH, in January of 2018 from the Norican group, Mingzhi Technology Leipzig GmbH has been established as our new European production and commercial facility. As part of the Mingzhi Technology family, this location will continue to produce high quality core shop equipment and collaborate with the Suzhou technical group to develop and produce innovative core machine products and services for current and future global customers. Additional sales and marketing offices are located near Venice, Italy.

The Leipzig operation, established in 1996, includes a team of approximately 30 employees, with a commercial and technical office and an adjacent production facility located Southwest of the city center. Currently, this production site produces some of our lineup of core shooters suitable for all core processes including hot box, cold box and inorganic processes, gassing units and sand preparation equipment.

Company Mingzhi Technology produces:

Coreshooters

Our innovative core machine series A+, D and MP are in a wide range of sizes to fit customers process requirements.

A+ Series

Flexible and Precise

The A+ series has been designed to offer significant precision of movement, flexible core production and high reliability. With a low maintenance design, it is compatible with various core box material use, including cold box and hot box processes. Other characteristics of the A+ series include:

- Operator-friendly use;

- Vertical and horizontal parts from 2 to 6-part core boxes;

- Fixed shooting head and sleeveless sand magazine; easy to maintain;

- Quick tooling locking through hydraulic clamping cylinders;

- Sand magazine with sleeve-free design and level laser control;

- Integrated gas generator.

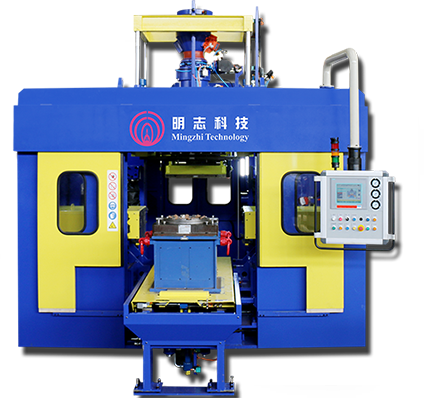

D Series

Speed and Strength

The D series was designed to offer significant precision of movement, quick dry cycle time, a heavy-duty frame and a pit-free design. Other characteristics of the D series include:

- Suitable for inorganic, hot box and cold box processes;

- High core box closing force;

- Shifting of sand magazine and gassing hood;

- Shuttle for quick rear tooling change (optional);

- Shooting plate cleaning device (optional);

- Quick tooling locking through hydraulic clamping cylinders;

- Vertical and horizontal parts;

- Top and lower ejection;

- Sand magazine with sleeve-free design and level laser control;

- Adjustable quantities in the sand magazine using PLC;

- Centralized lubrification;

- Operator-friendly use;

- Low maintenance design.

MP Series

Multipurpose Core Shooter

The MP Series provides you with core boxes that feature multiple parting lines. It is adjustable to existing core boxes and suitable for all core processes.

Other characteristics of the MP series include:

- Rugged design suited for foundries;

- No pit required.

Non-Series Machines

In addition to standard core machine series, we provide a range of customized core machines for your specific needs. Have a look through our gallery at some examples of the non-series machinery we can offer where necessary for different processes, including: Coldbox (Isocure, S02, C02), Hotbox/Shell and Inorganic.

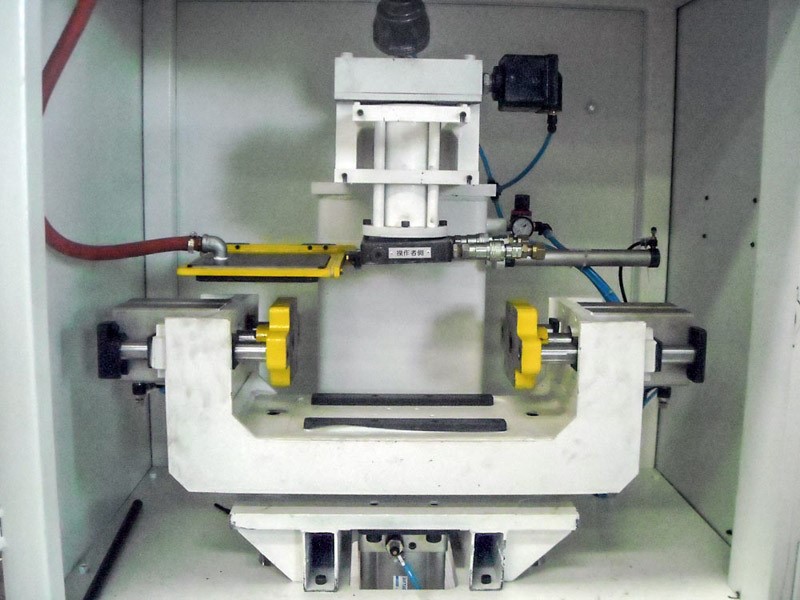

Lab Series

Ensuring Strength and Reliability. Lab testing devices produce pull and bend strength testing of sample cores.

Some further characteristics of our Lab machine include:

- For cold box, Inorganic and hot box processes;

- Samples produced automatically;

- Max. shooting capacity from 1 to 7 liters;

- Vertical part core box;

- Operator-friendly use;

- Low maintenance design;

- Rugged design suited for foundries;

- No pit required.

EP Series

For Small and Medium Cores. The EP Series is our core shooter designed for small and medium-sized cores. All core boxes feature multiple parting lines. The series is adjustable to existing core boxes.

Other characteristics of the EP series include:

- For cold box, inorganic and hot box processes;

- Shifting of sand magazine and gassing hood;

- Shooting plate cleaning device (optional);

- Quick tooling locking through hydraulic clamping cylinders;

- Vertical and horizontal parts core box;

- Sand magazine with sleeve-free design and level laser control;

- Adjustable quantities in the sand magazine using PLC;

- Centralized lubrification;

- Operator-friendly use;

- Low maintenance design;

- Rugged design suited for foundries;

- No pit required.

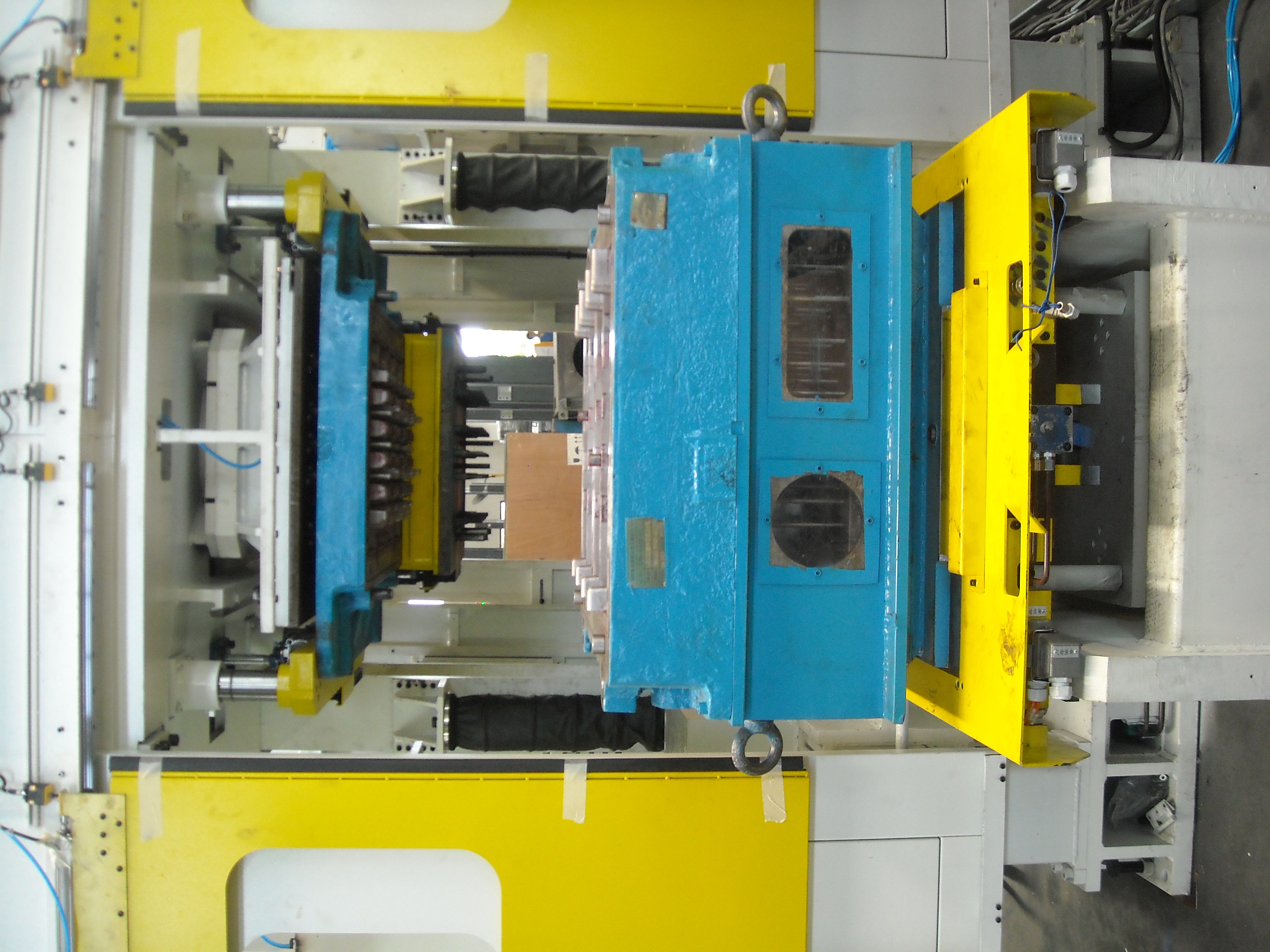

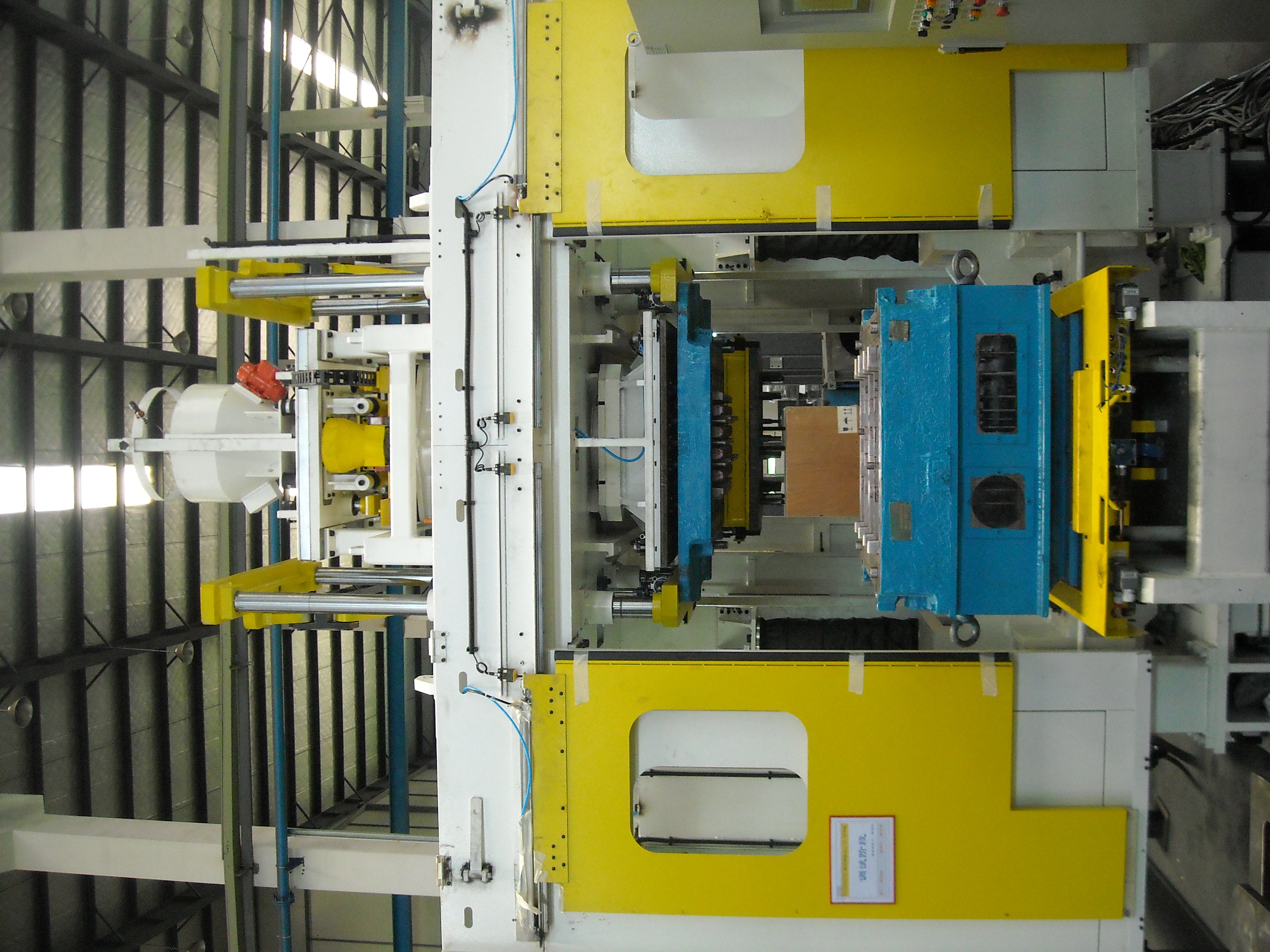

LP Series: The core shooter for manufacturing large cores

Through innovative design we can offer you tailor-made solutions for high productivity. This range of large core shooters has evolved from proven, reliable standard solutions which we customized to expressed customer requirements.

Advantages:

- No pit required, even for big strokes;

- Minimal cleaning required;

- Highly efficient shooting system.

RP Series

The multi-station core shooting machine for high performance.

- The upper part of the machine consists of a rotary device for different shooting units;

- Motion sequence from the clamping units with measuring system and proportional control system;

- Automatic clamping system;

- Shooting plate cleaning station;

- Low maintenance system;

- Rugged design suited for foundries;

- No pit required.

MRD Series: Hot Box core shooter

The MRD Series is our core shooter designed for vertical and horizontal core boxes. The core box heating may be done with electrical heating elements or by gas burners.

Other characteristics of the MRD series include:

- For Hot Box process;

- Sand hopper, sand magazine and shooting plate cooled by water;

- Top shooting system;

- Quick tooling locking through hydraulic clamping cylinders;

- Vertical and horizontal parts core box;

- Sand magazine with sleeve-free design and level laser control;

- Centralized lubrification;

- Operator-friendly use;

- Low maintenance design;

- Rugged design suited for foundries;

- No pit required.

MRZ Series: Shell process core blower

The MRZ Series is our core shooter designed to run a single core box or two core boxes at the same time. The core box heating may be done with electrical heating elements or by gas burners.

Other characteristics of the MRZ series include:

- For Shell process;

- Sand hopper, sand magazine and shooting plate cooled by water;

- Fixed top-down blowing system;

- Rollover system to make the hollow cores;

- Automatic core box tilting (90°) to eject the cores on belt;

- Quick tooling locking hydraulic clamping cylinders;

- Vertical parts core box;

- Sand magazine has sleeve-free design, level laser control;

- Centralized lubrification;

- Operator-friendly use;

- Low maintenance design;

- Rugged design suited for foundries;

- No pit required.

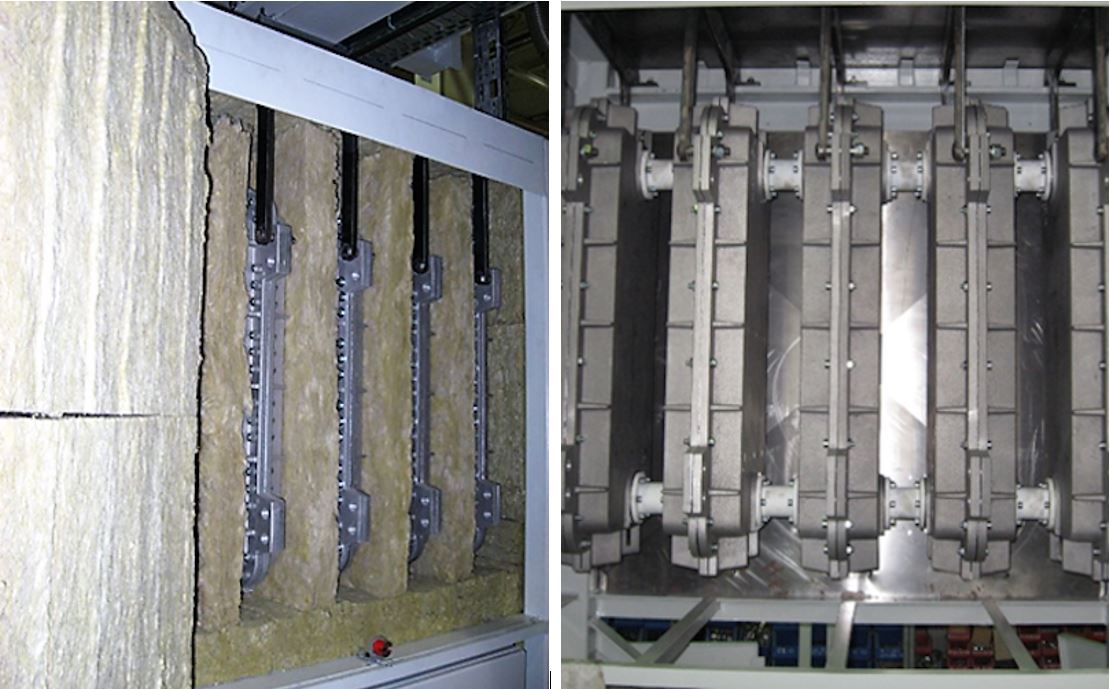

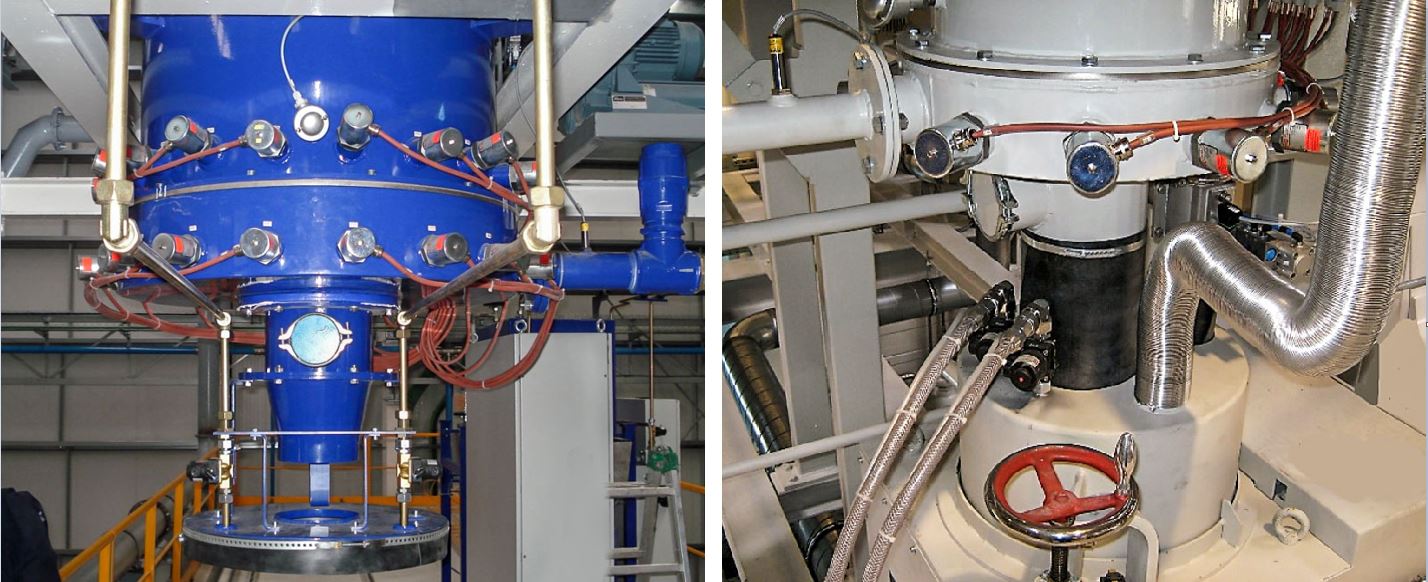

Gassing units

Presented amine LGD gassing units with high accuracy dosing capability offer the benefits of reduced catalyst consumption and repeatability. To suit your production needs, we offer units as either stand-alone devices with an integrated PLC, or devices fully integrated into the core machine. Our gas generators are designed and built according to ATEX regulations and CE safety standards.

We also provide complete gas generators and air heaters for processes such as SO2 and CO2.

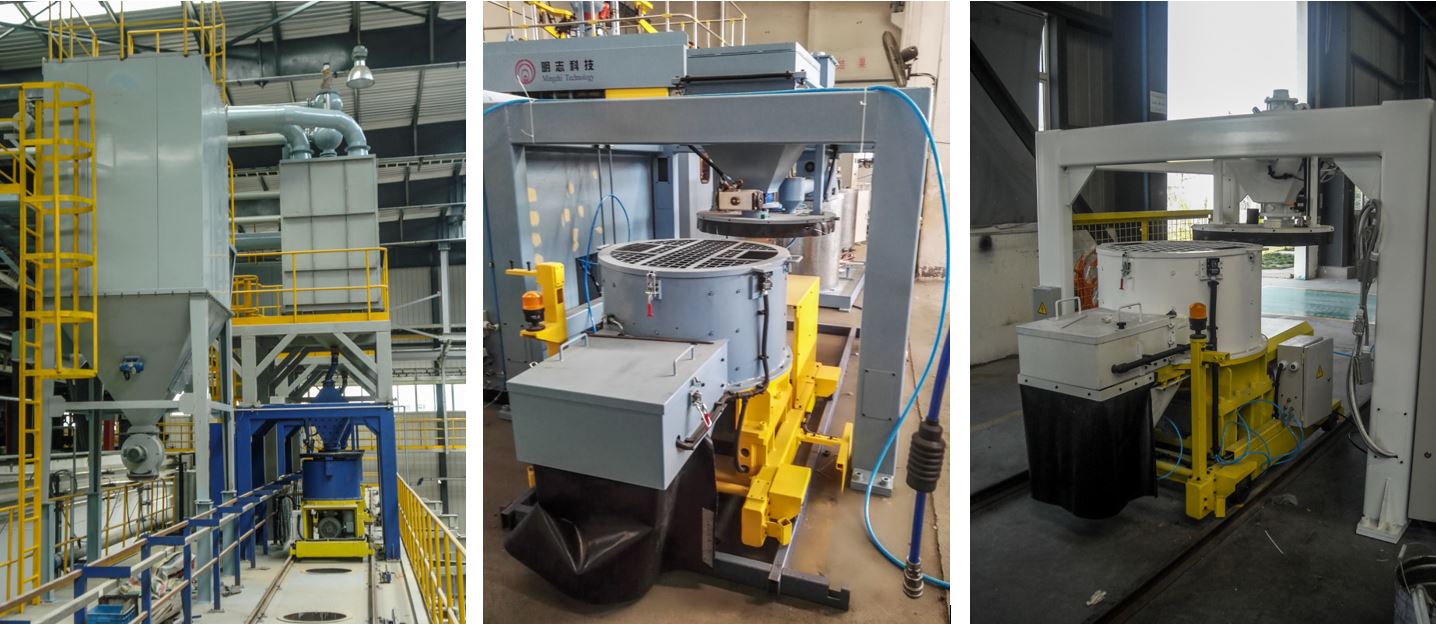

Sand Preparation Systems

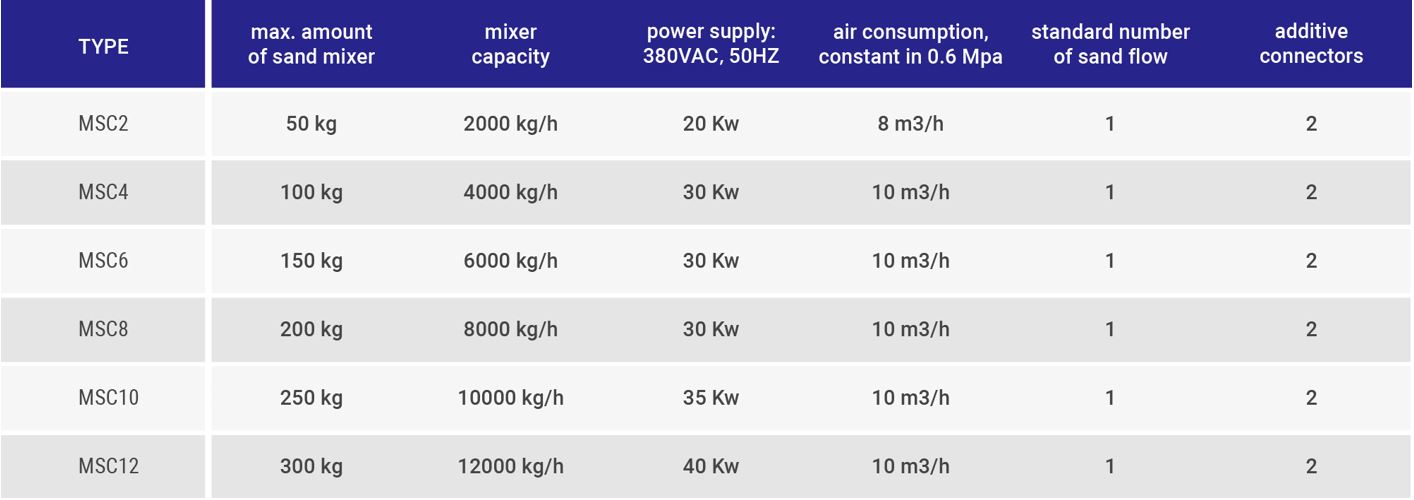

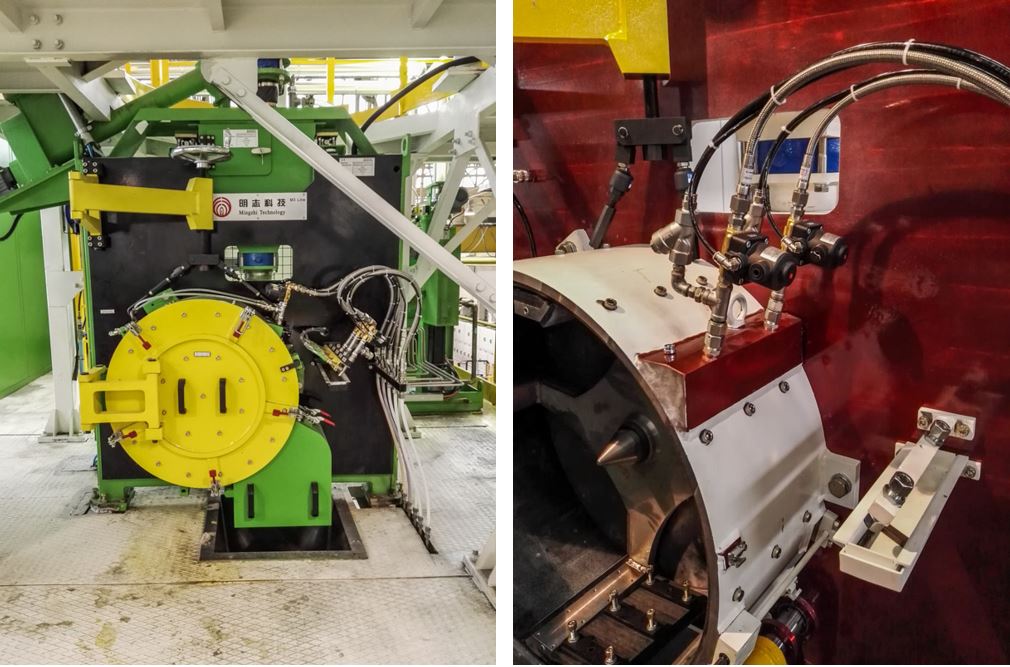

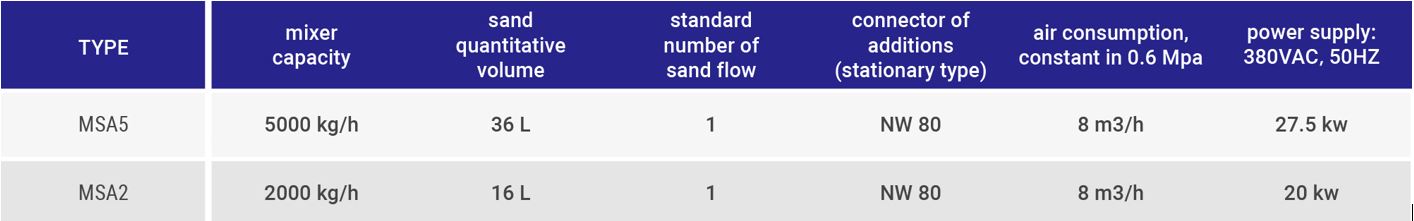

Sand Mixers

The Sand Mixers from Mingzhi Technology are available as batch or high-speed units. Depending on your core production requirements, all our mixer lines can feed single or multiple core machines.

- Batch Mixer

Our MSC batch mixer is available either as a stand-alone device or may be mounted on a trolley to feed multiple core machines. The round wall and bottom of the batch mixer are covered by a wearproof material that may be easily replaced. The mixer’s hard steel blades are treated and removable and they rotate by means of a motor gear. The sand outlet gate opens and closes using a pneumatic cylinder. This batch mixer features a translation motion driven by a gear motor, that includes a frequency device for speed adjustment.

- High-Speed Mixer

Our MSA high-speed mixer is a stand-alone device suitable for feeding a single machine. Through the addition of a belt or trolley, multiple core machine feed is also possible. A fast cycle time allows for mixing small quantities of sand and binders. The round wall is covered by a wear-proof material that may be easily replaced. This mixer’s hard steel blades, which are treated and removable, spin horizontally by means of a motor gear. The sand outlet gate opens and closes by means of a pneumatic cylinder.

Binder Dosing

Our volumetric resin-dosing device guarantees precision and repeatability. Volume levels are measured by means of a capacity sensor positioned along the calibrated dosing tube.

Our centralized binder supply system allows customers to have a dedicated room for storing commercial binder drums. This system supplies the binder to the heated tank situated near the mixer.

Sand Heater

Our sand heater, known as the Fluid bed heater system, is used for heating and dedusting the sand. It is installed between the weighting system and the mixer.

The sand at an input temperature of 5° can be heated to a constant temperature of 20- 25°. The hourly output ranges from 1,5 to 5,0 ton/h.

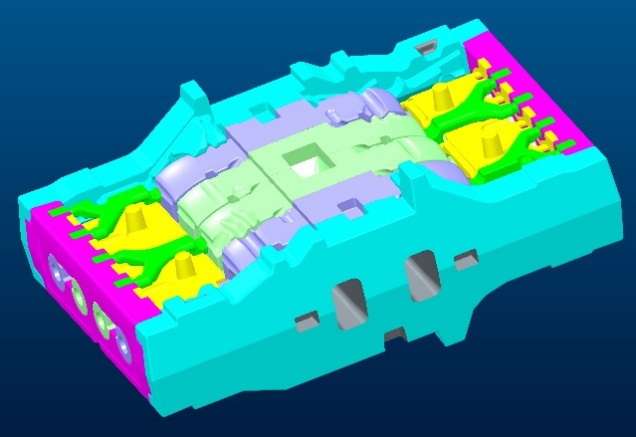

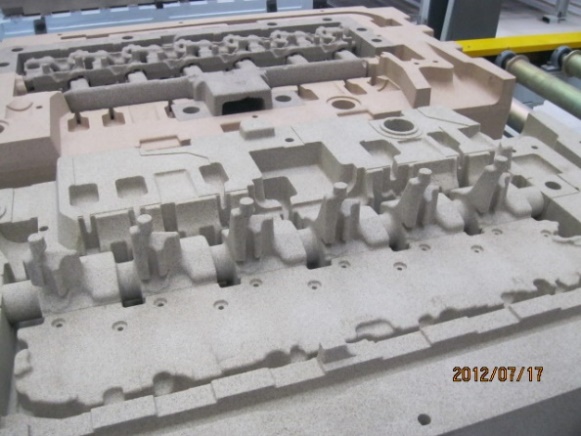

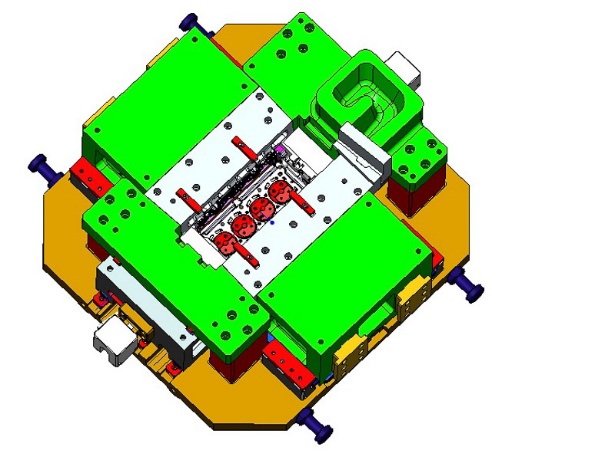

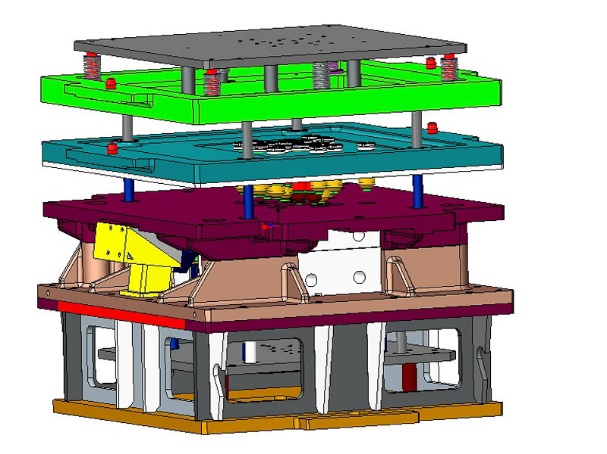

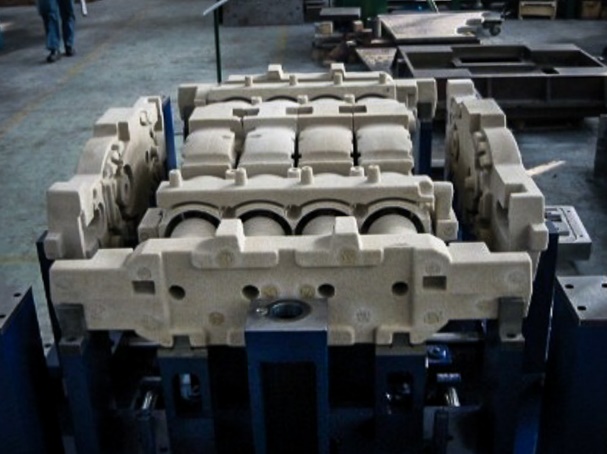

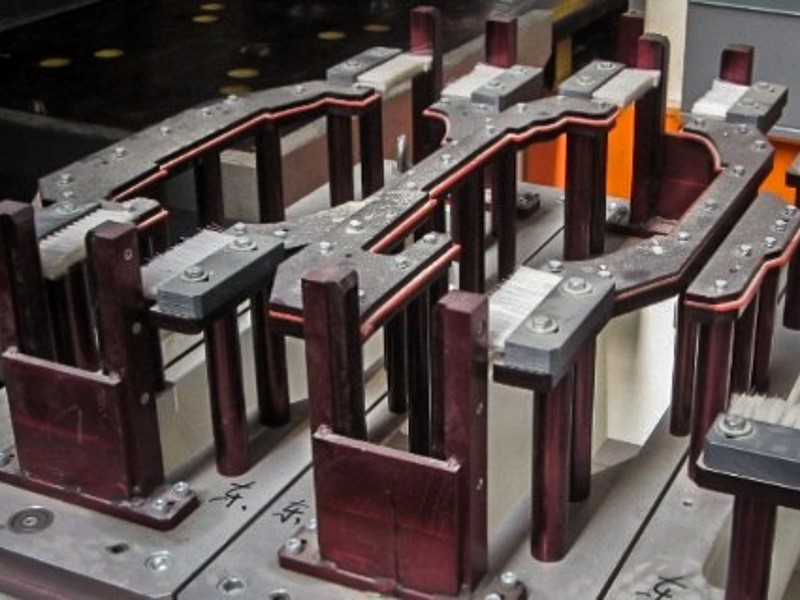

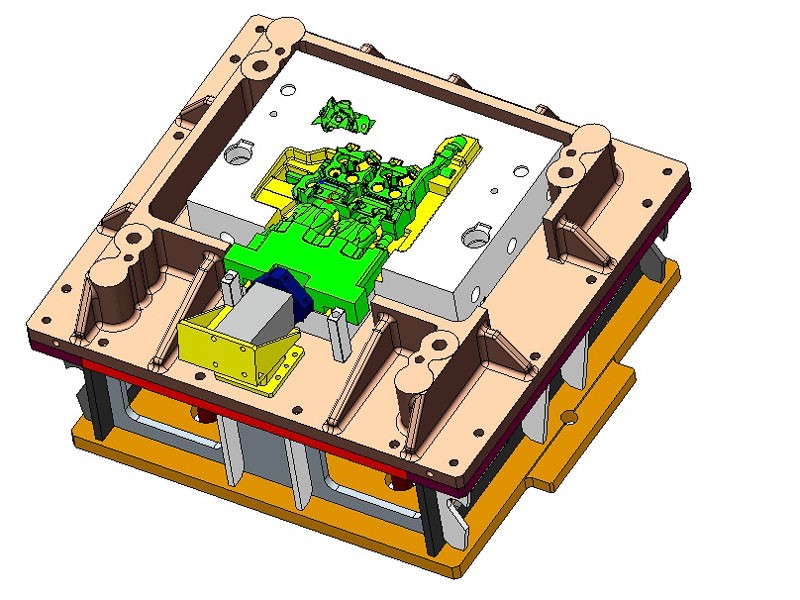

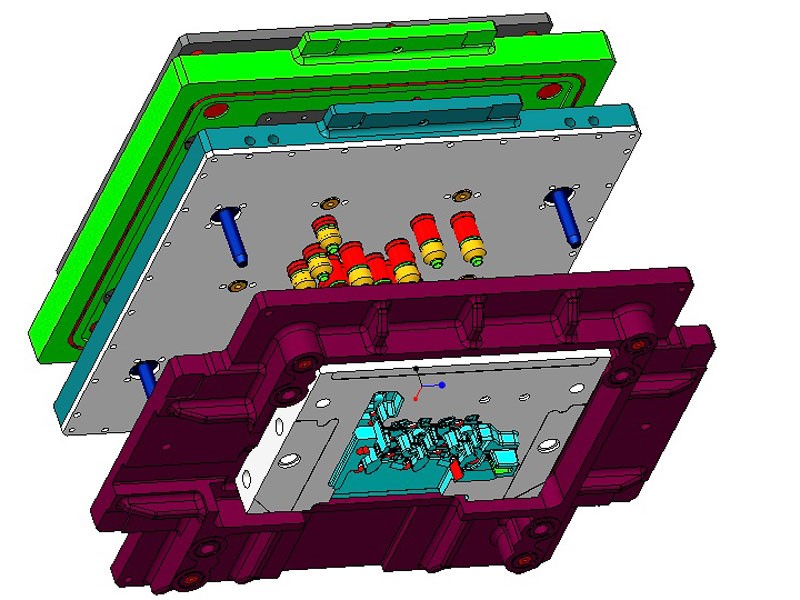

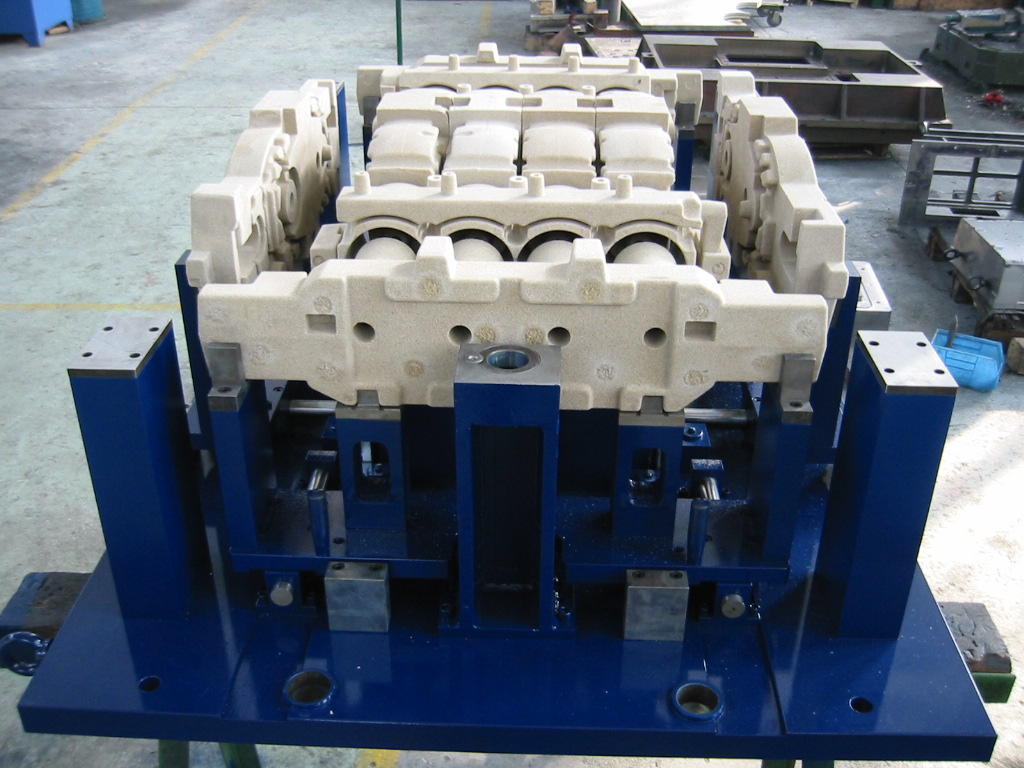

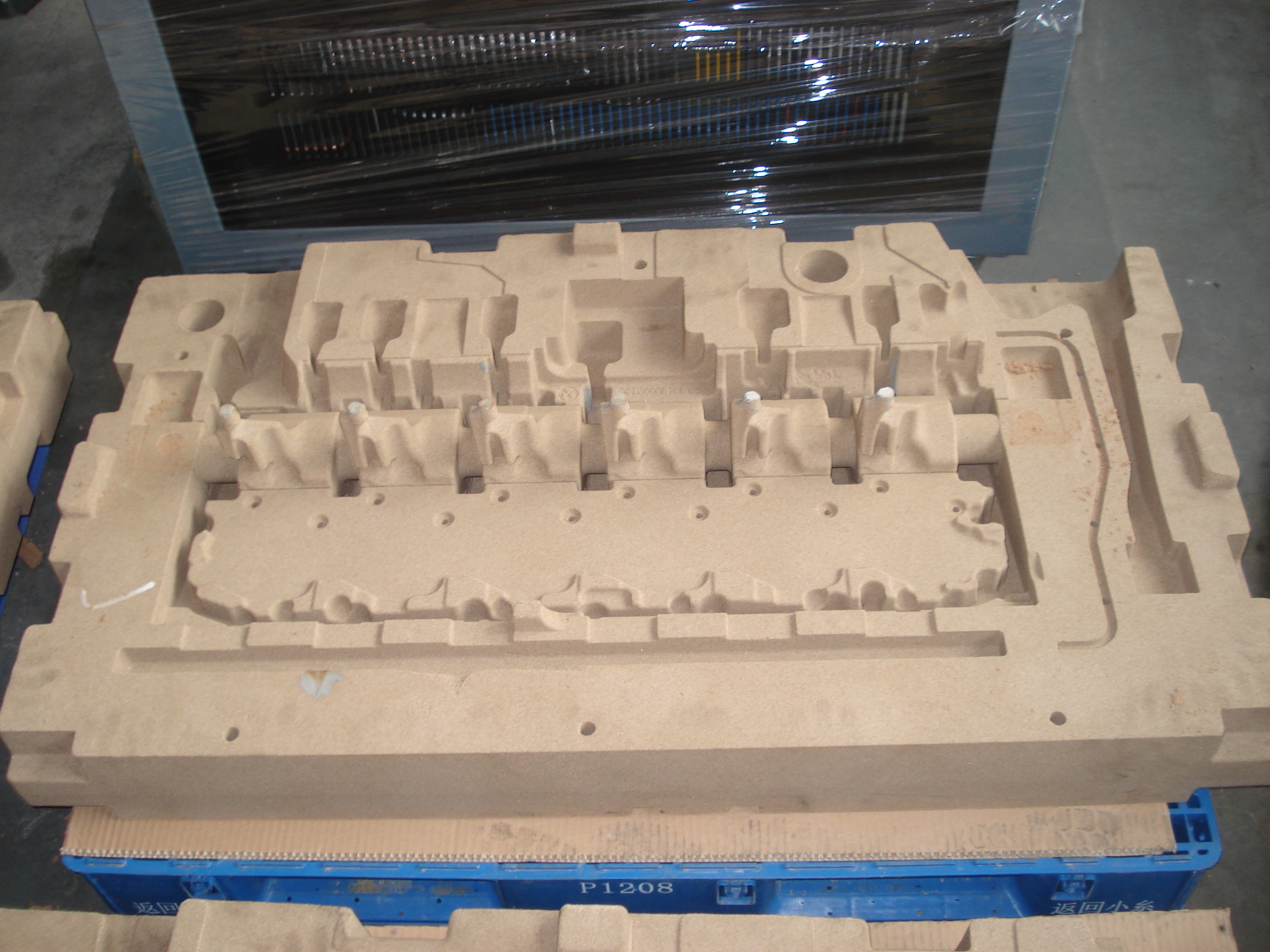

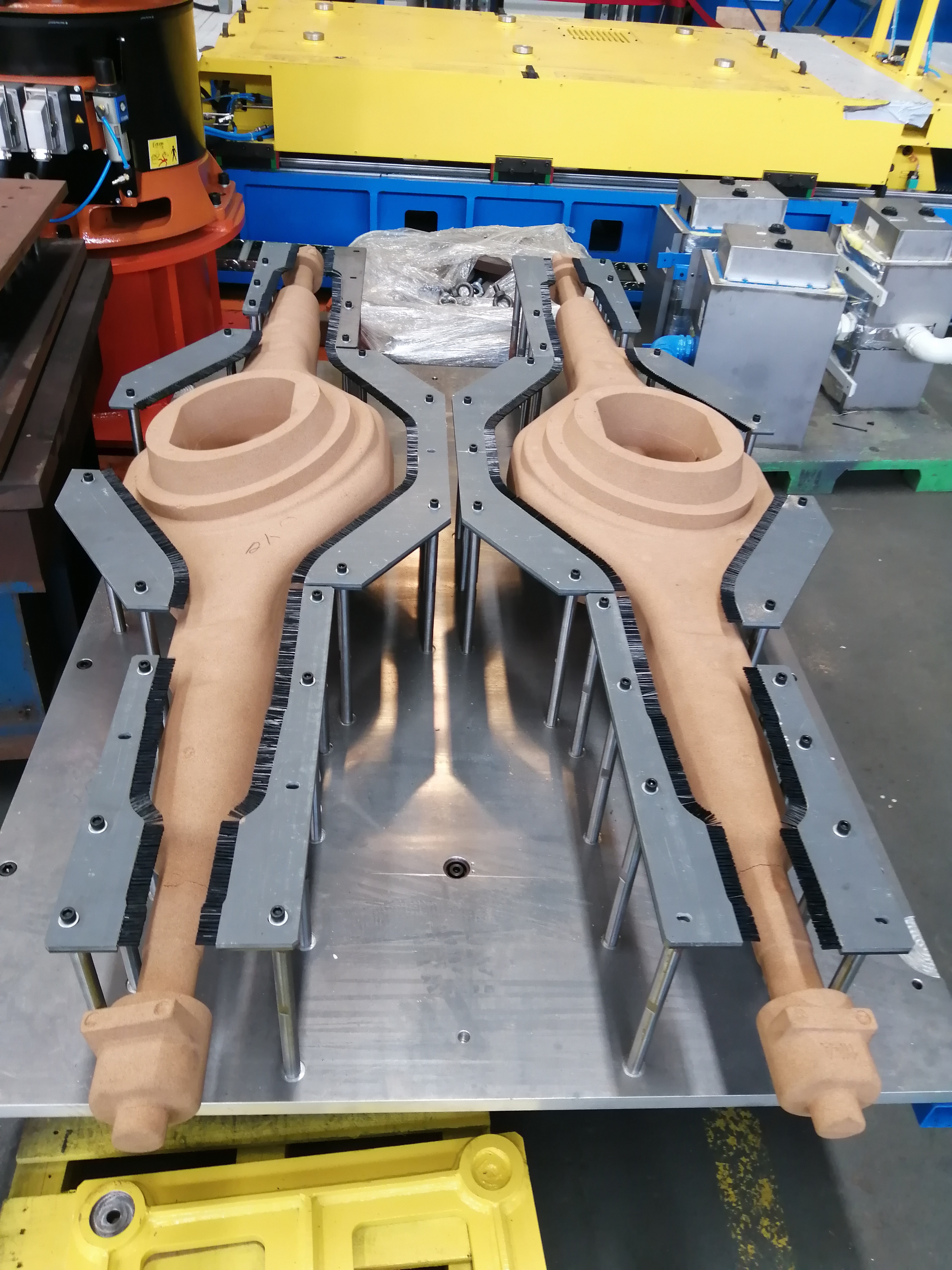

Tooling

Mingzhi Technology’s Tooling Division specializes in the engineering and manufacturing of permanent molds, semi permanents molds, fixtures, and core boxes for different processes, such as Cold-Box, Hot Box, Inorganic and shell molding. We use only the latest technology in CNC machining and EDM validation and provide the following in-house services:

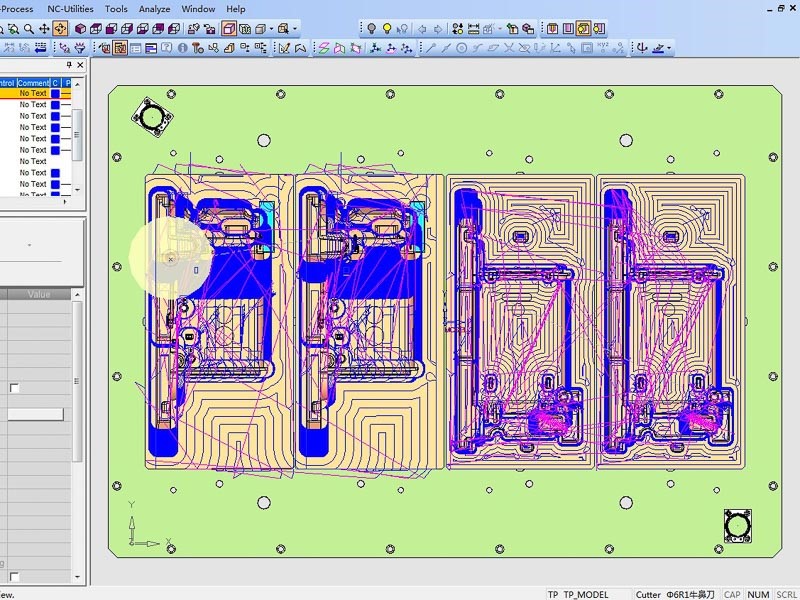

Engineering and simulation

- CAD/CAM software (Pro/E Wildfire 3.0, AutoCAD Inventor);

- 3D mathematical modeling;

- Mold structure design;

- CAM programming calculation.

Manufacturing and Testing-Inspection

- CAM/CNC machining centers with CEMATRONE7;

- Measuring instruments;

- Zeiss CMM Dimensional and checking report;

- EDM validation.

Trial Production

- Core box testing;

- Core production in batch volume.