Launch of seven automatic die casting complexes for the production of aluminum and bimetallic radiators in the central part of Russia

The project started on 01.02.2021

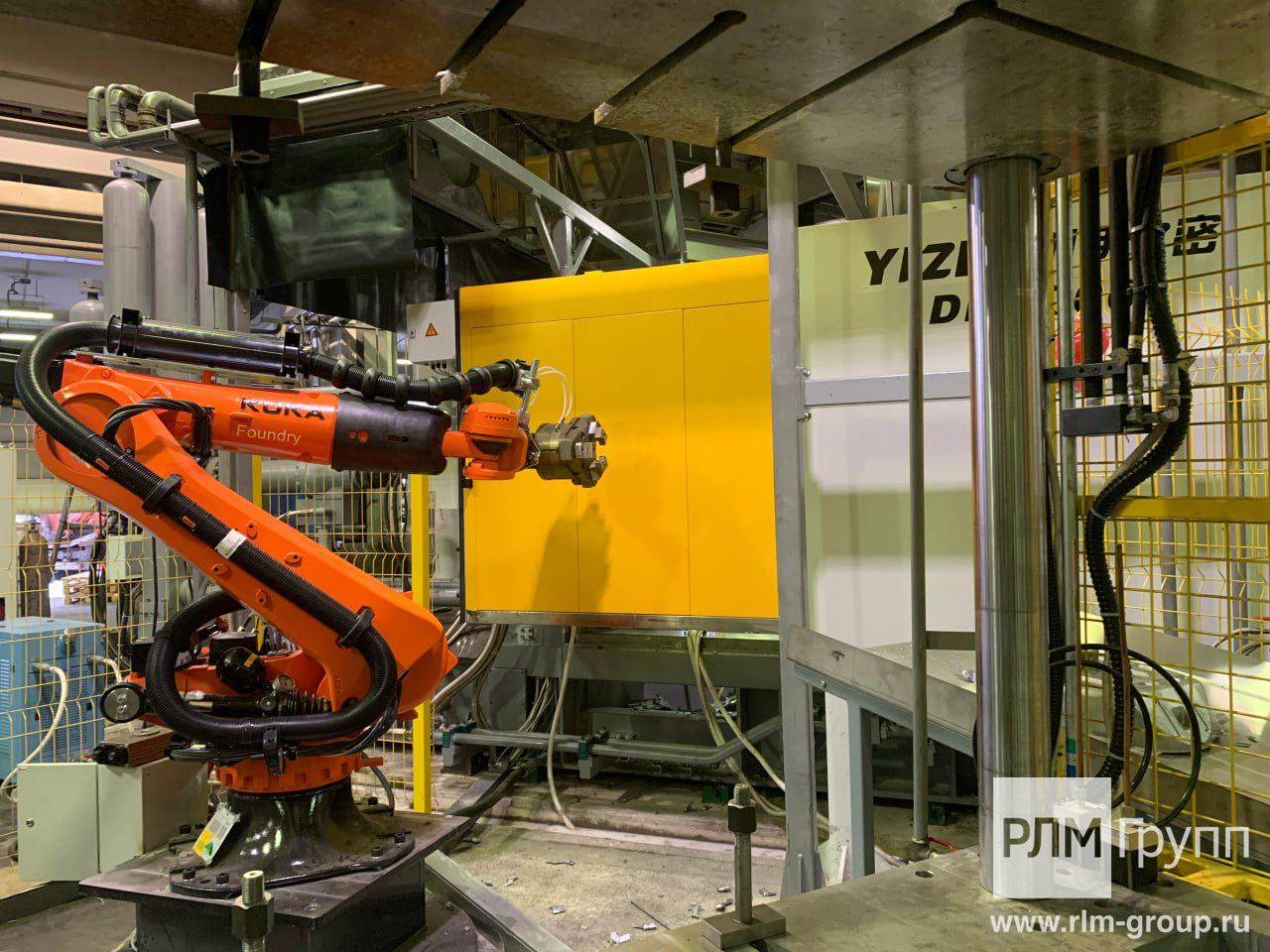

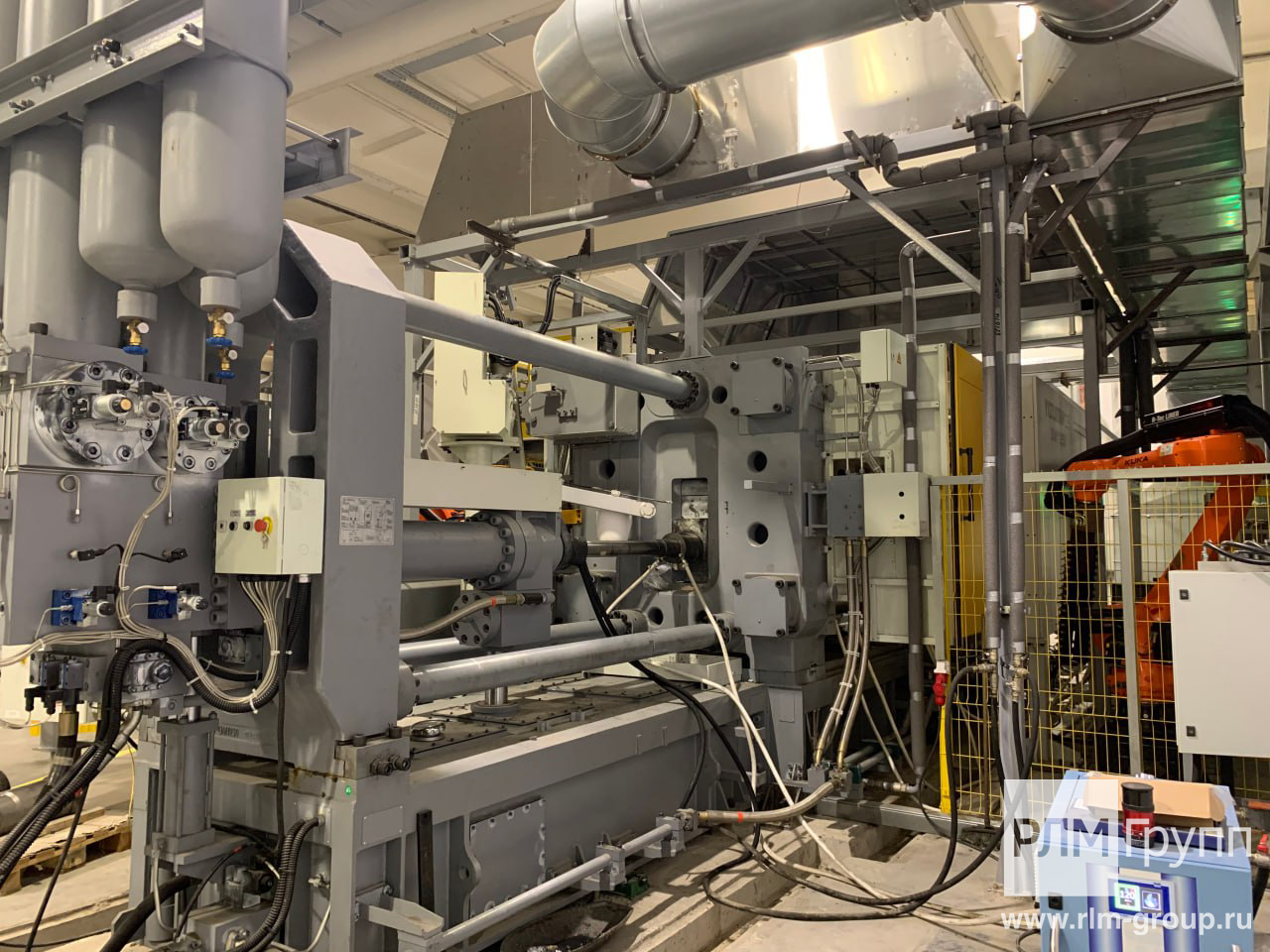

As a part of the modernization and expansion of production, the largest project in the industry was implemented. The project includes the launch of seven fully automated Yizumi die casting complexes based on DCM with a locking force of 1200 tons. Foundry complexes are designed for casting aluminum and bimetallic radiators on double molds with an axial distance of up to 500 mm with a total increase in design capacity by 7 million pieces of finished products per year.

The main characteristics of foundry complexes:

- Locking force — 1200 ton;

- Cycle time from the moment the melt is fed to the casting is placed on the finished product conveyor — 44-46 seconds;

- The capacity of one complex is at least 3000 castings/day;

- Fully automated process using ABB industrial robots, turntables and conveyors for production automation.

This modernization allowed the company to take a leading position in the market of domestic radiators, as well as reduce the share of imported products presented in Russian retail chains.