YIZUMI

High pressure die casting machines, tooling

YIZUMI was founded in 2002 in Guangdong province, China. Specializing in the production of machines and automated systems for injection molding, YIZUMI offers a complete turnkey solution, including the design and manufacture of equipment and accessories.

- 400,000 m2 of production facilities;

- 5 major commercial divisions;

- 3,000 employees.

Today, YIZUMI company is represented in all corners of the world: 3 main production areas have been created in China — in Gaoli, Usha (Shunde) and Wujiang (Suzhou). In addition, the YIZUMI plant in India was officially commissioned, as well as the new YIZUMI — HPM production facilities in North America (Ohio, USA). Total production area of the company is 400.000 square meters, where employs 3,000 employees.

Headquarters in Gaoli, Shunde occupies a land area of 80,000 sq.m

Factory in Wusha, Shunde:

Factory in Wujiang, Suzhou:

Factory in Ohio, United States:

In 2020, Yizumi is a model of the field of processability of the equipment produced (R&D costs in 2019 alone amounted to $100 million) and currently offers 9 series of die casting machines with a locking force of 180 to 4500 tons.

Cold chamber Die Casting Machines:

- DM Standard Series Die Casting Machine;

- DM Heavy Duty Series Die Casting Machine;

- ARC Real Time Control Series Cold Chamber Die Casting Machine;

- H Series Precision Die Casting Machine;

- H Series Heavy-duty Die Casting Machine;

- SM Series servo Die Casting Machine.

Hot chamber Die Casting Machines:

- HM Series Hot Chamber Die Casting Machine;

- HM-H Series Hot Chamber Die Casting Machine;

- HPM Thixomolding Machine.

Peripherals for Die Casting Cell

Cold chamber Die Casting Machines:

DM Standard Series Die Casting Machine (The locking force 1.800-9.000 kN)

Yizumi’s main line of die casting machines is designed and manufactured based on European standards. It has an optimal ratio of performance, reliability and cost.

- Ideal for the production of castings in the automotive industry, in electrical engineering, in the production of household appliances, etc.

- The control system is based on Siemens PLC. It is characterized by stable, fast, safe and reliable operation.

- High precision and stability of parameters of quality of the castings.

- High-speed pressing unit (up to 8m / s), switching to pre-pressing mode 15 MS.

- Can be used to create a fully automated casting cell.

DM Heavy Duty Series Die Casting Machine (The locking force 10.000-30.000 kN)

- High-precision and reliable pressing control technology based on proportional hydraulic equipment; 4-stage control of pressing speed and pressure; hydraulic accumulators with an independent circuit.

- Proportional pressure and flow control system with multi-stage pressure and speed control, as well as mold closing protection function.

- Advanced mold height adjustment technology that allows you to set the mold at low pressure.

- Control system based on Siemens PLC with touch-screen display and process parameters control function, fault diagnosis system and the ability to save parameters for 100 molds.

- Highly reliable electrical and hydraulic components of world-famous brands (Parker / Bosch Rexroth / Vickers / Yuken).

- Two-circuit centralized lubrication system, independent plasticized Albany grease.

- Double hydraulic protection, high-speed hydraulic ejection device.

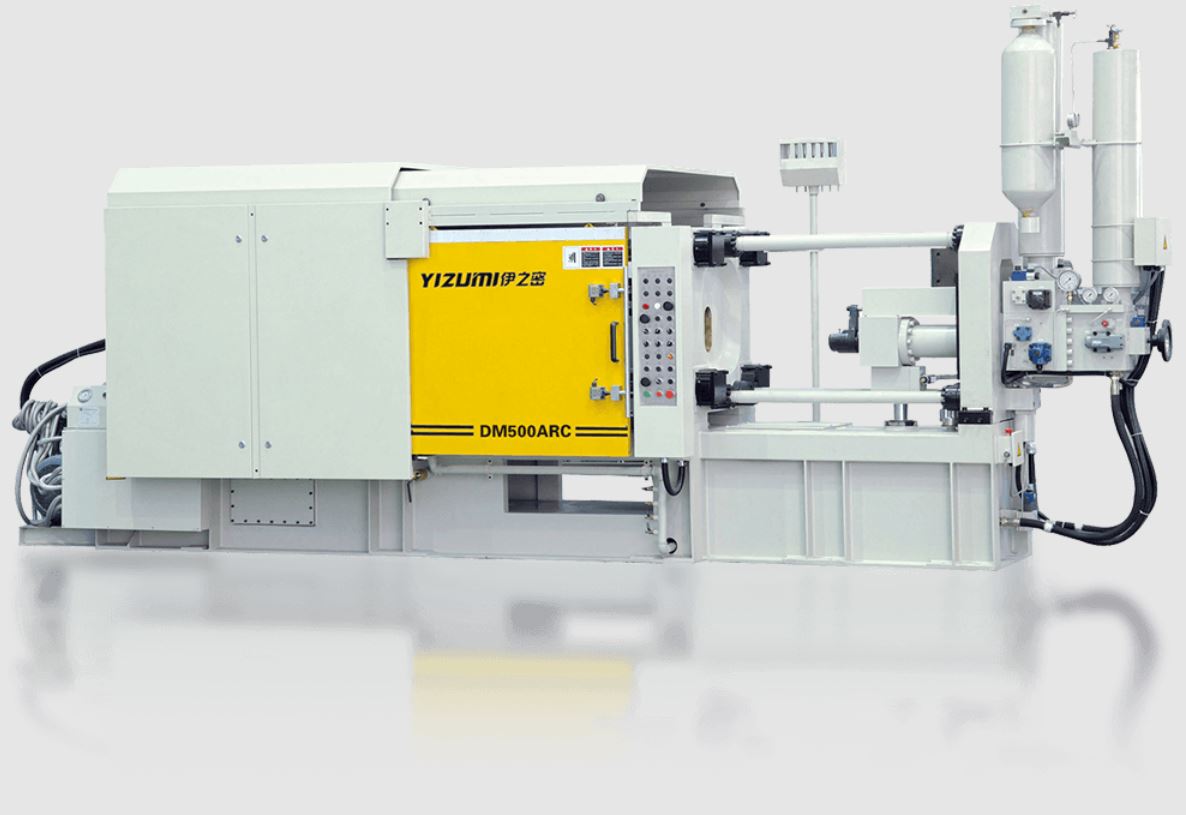

ARC Real Time Control Series Cold Chamber Die Casting Machine

Due to economic globalization, the demand for high-quality and precise casting is steadily growing. Using world-class technology, YIZUMI has developed ARC series machines with real-time control of the pressing process, providing ultra-high performance.

Features:

- Control of the pressing process with feedback;

- Multi-stage speed control;

- Uniformly accelerated the first phase of the pressing;

- Plunger braking function at the end of the pressing phase.

Advantages of the ARC series:

- High repeatability of parameters of the casting;

- Convenient process control settings;

- Effective elimination of porosity defects;

- Improved casting quality.

Main characteristic:

- Max. pressing speed: 8m/s — 10 m/s;

- Setting range: 0.05 m / s — 8 m/s;

- Pre-pressing set time: 10ms — 15ms.

Precise feedback control technology:

- More than 8 steps of convenient parameter setting;

- The scanning cycle control in real time;

- Precision measurement and real-time control with feedback of pressing; position, speed and pressure;

- A function of even acceleration;

- The brake function of the plunger.

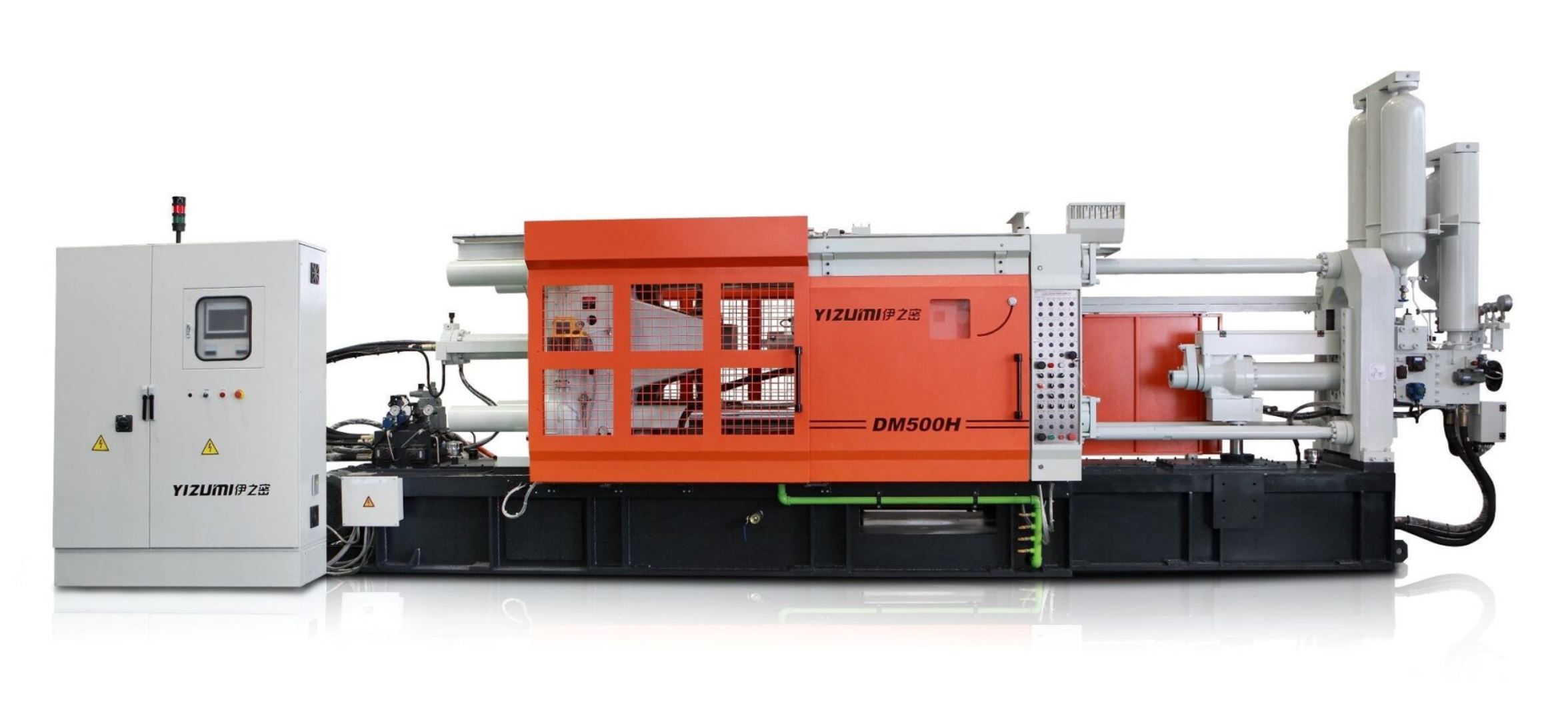

H Series Precision Die Casting Machine (The locking force 1.800-9.000 kN)

Based on many years of experience and having worked through more than 2,000 customer suggestions for improving the level of our machines, fully studying the standards of the American company HPM in the field of large-capacity machines, constantly carrying out research and development work, making more than 50 key and 100 auxiliary improvements, the YIZUMI technical team launched a series of H — high-tech die casting machines.

- The main line of die casting machines of the company Yizumi. HPM concepts were used in the development of these products.

- The semi-closed control loop in the pressing system and the optimized hydraulic system reduce the cycle time by 15%.

- Ideal for the production of precision products in electrical engineering, electronics, automotive and other high-tech industries.

- The control system is based on Siemens PLC (touch screen) with stable, fast, safe and reliable operation.

- Using only first-class components from the world’s leading manufacturers allows you to achieve high precision and stability of casting, combined with reliability and trouble-free operation.

Main advantages:

- High quality standard. Based on HPM standards and technologies, the machines have increased reliability, stability, durability and performance.

- Accuracy and stability. The rigid integrated structure of the plunger ensures high accuracy and stability of the pressing system. A closed loop design is possible to further improve quality and performance.

- Durability. Reinforced locking Assembly. The plates are covered with high-strength alloy steel, which increases the strength and fatigue strength.

- Security guarantees. In accordance with EU safety standards.

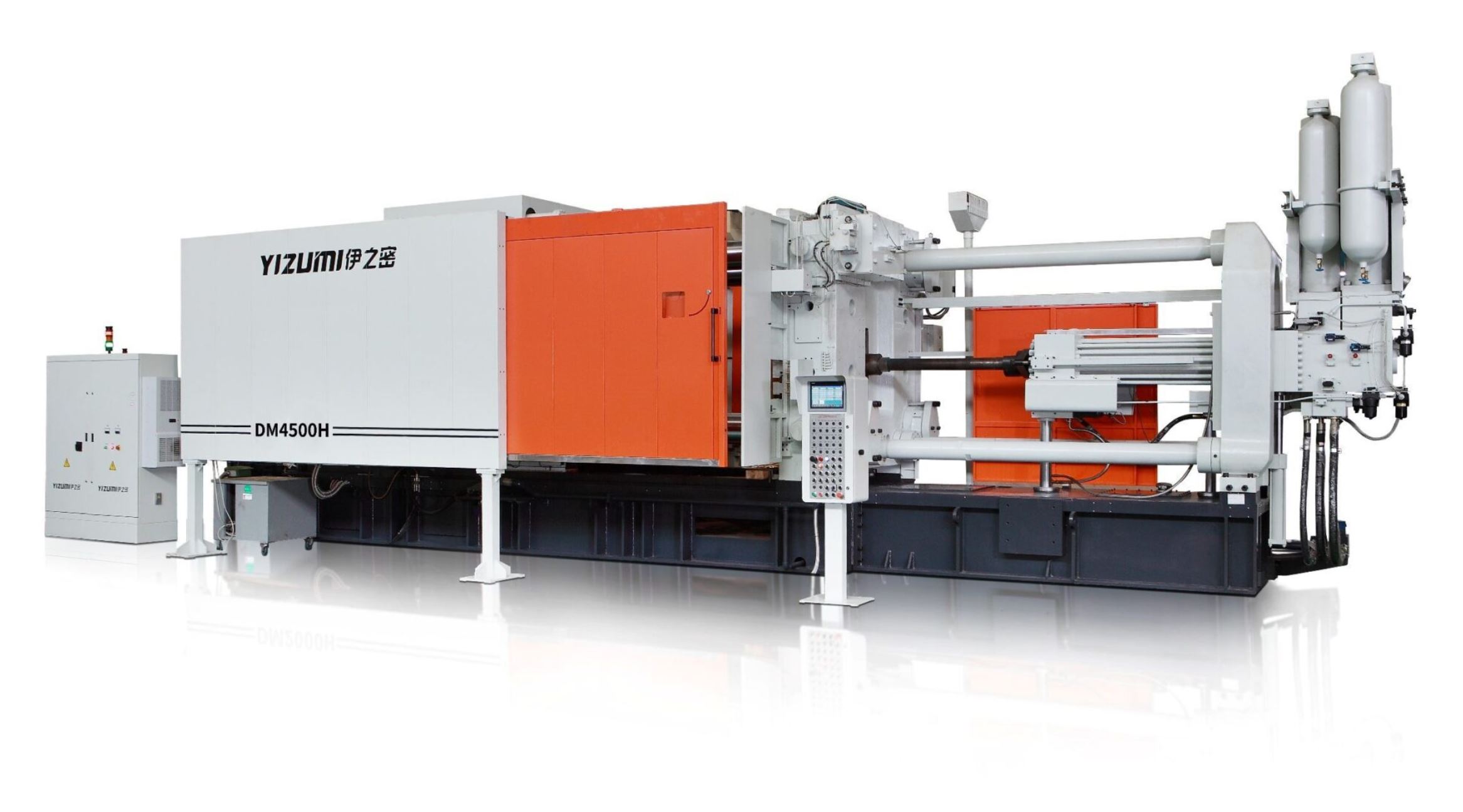

H Series Heavy-duty Die Casting Machine (The locking force 10.000-45.000 kN)

- Reinforced locking unit: the surface of the plates is covered with a heavy-duty steel alloy.

- Fully updated configuration extends the customer’s operational experience. Complying with EU standards, the machine has a working panel that embodies the principles of engineering design for industry and a built-in 12-inch color touch display from Siemens.

- The locking unit complies with EU standards and is equipped with electro-hydraulic safety valves to effectively prevent accidental closing of the mold. Protection devices have been added to the pressing unit, which are switched to prevent accidental damage. High-pressure hoses are equipped with protection devices.

- The pressing system based on the standards of the company HPM.

- Reliable and accurate system for adjusting the height of the mold.

- A centralized lubrication system with the best performance guarantees the desired effect. It is easy to operate and maintain. Each circuit has a remote alarm function for insufficient pressure.

- Intelligent interactive quality control system. Real-time display of pressing profiles and interactive diagnostics system guarantee stable quality during mass production of finished products.

- Real-time control system (optional). A new generation of real-time control technology allows you to achieve precise speed control with feedback, stable and reliable repeatability of characteristics and implement the plunger braking function.

SM series servo Die Casting Machine (The locking force 1400-9000 kN)

Based on the latest developments in the field of servo drives and our own experience in the production of servo-driven injection molding machines, YIZUMI launches the SM series machine with reduced energy consumption. All the advantages of servo drives are now also in die-casting machines.

- Depending on the operating conditions, energy consumption is reduced by 40-70% compared to traditional machines

- Quick response of the servo system: the pressure gain time to 100% is only 30ms, which reduces the cycle time by another 5-12%

- Reducing the oil temperature by using a servo drive increases the service life of hydraulic components and seals, which in turn reduces maintenance and repair costs, and ultimately makes your production more competitive.

Hot chamber Die Casting Machines:

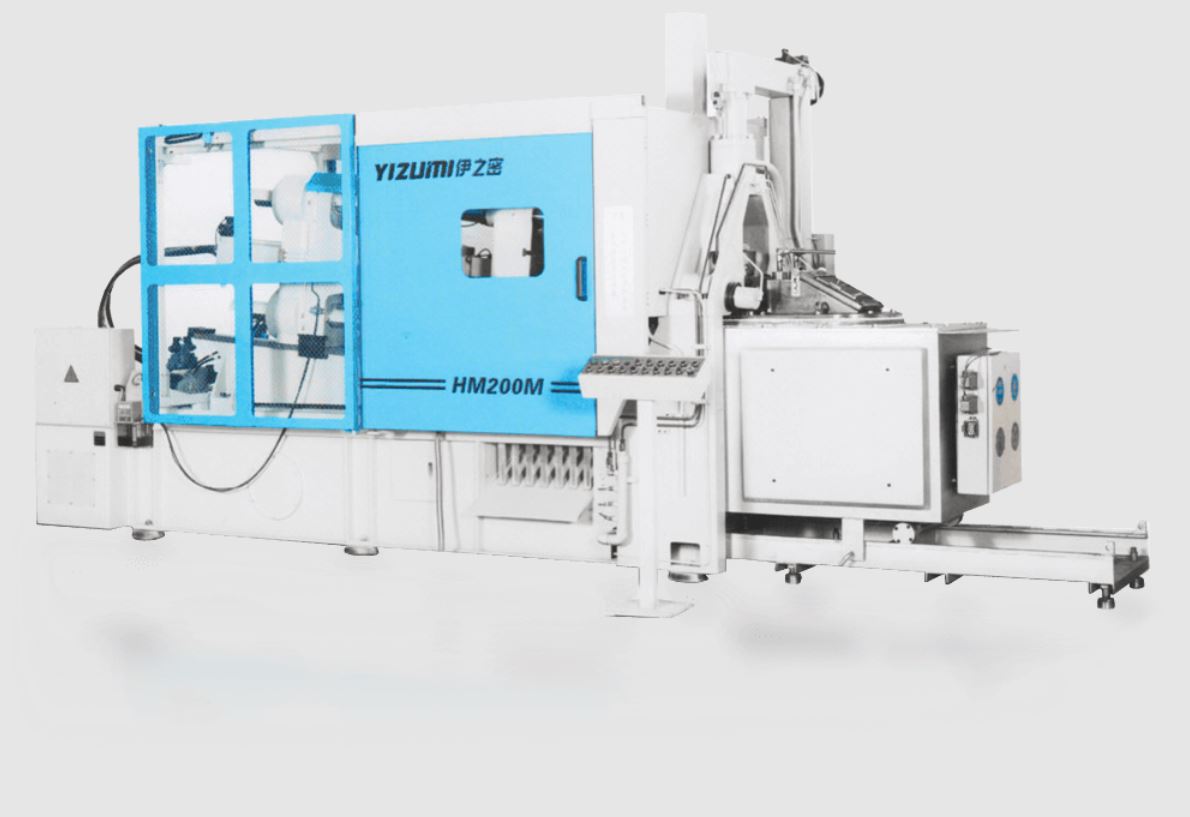

HM Series Hot Chamber Die Casting Machine (The locking force 900-4000 kN)

HM series di casting machines with hot pressing chamber are available in 12 sizes with locking forces from 8 to 400 tons. They are the ideal solution for casting products of medium and high complexity with a weight of up to 7.5 kg. The machines in this series meet three basic principles: easy operation, trouble-free operation and flexibility, and their carefully designed design ensures maximum performance.

- Two pressing phases, maximum speed up to 5m/s, controlled from the display.

- Improved system of heating of the gooseneck has the function of alarm high and low temperature.

- Automatic centralized lubrication system.

- Uniquely designed piston accumulators with increased capacity to provide unsurpassed speed and accuracy of the process.

HM-H Series Hot Chamber Die Casting Machine (The locking force 1.800-2.000 kN)

HM — H series hot chamber die casting machine is high performance and reliable.

- The pressure and speed are controlled by a proportional valve. The injection parameters are set on the Siemens display screen.

- Specially designed high capacity hydraulic accumulators provide unsurpassed injection speed and accuracy.

- Improved system of heating of the gooseneck has the function of alarm about the high and low temperature.

- The injection system has three-phase control: slow injection, fast injection and pre-pressing. Three injection phases allow you to achieve high quality castings.

- The plates are made of hardened steel with greater strength and rigidity.

- The high-speed hydraulic circuit of the locking unit in combination with an independent high-capacity piston battery effectively increases the performance of the injection molding machine.

HPM Thixomolding Machine

Thixomolding — technology for casting metals in a semi-solid state. It allows you to produce complex parts made of magnesium and other metals with thin walls and high dimensional accuracy. No matter what the wall thickness of your parts is — 0.5 mm or 20 mm — you will always get high-quality castings. High injection speed, it only takes 12 ms to reach a maximum speed of 5m/s.

- Ideal for the manufacture of complex parts from magnesium alloys. The lifetime of the molds reaches up to 500,000 cycles.

- Machines with locking forces up to 1,250 tons.

- Many components of the machine are patented.

- Reduced cooling time of the product in the mold due to lower melt temperature.

Peripherals for Die Casting Cell

Automatic ladlers

Automatic ladlers are used for precise dosing of a certain portion of the melt into the shot-sleeve. The use of ladlers allows you to avoid undercurrents and overflows of metal and thereby increase the output of quality castings.

- With five linkages, twin gear driven to enhance arm speed and stability, it also increase production output.

- The case is mono-block; it greatly increases the precision of machine.

- The ladle arm forward / return and pouring / scooping are controlled separately by inverters, thereby increasing the ladle speed, easy to operate.

- The linkage model allows the arm to stop smoothly even at high speed, preventing the molten aluminum from easily spilling.

- The electrical components are controlled by PLC, using simple touch screen for setting, with build-in error code display for easier maintenance.

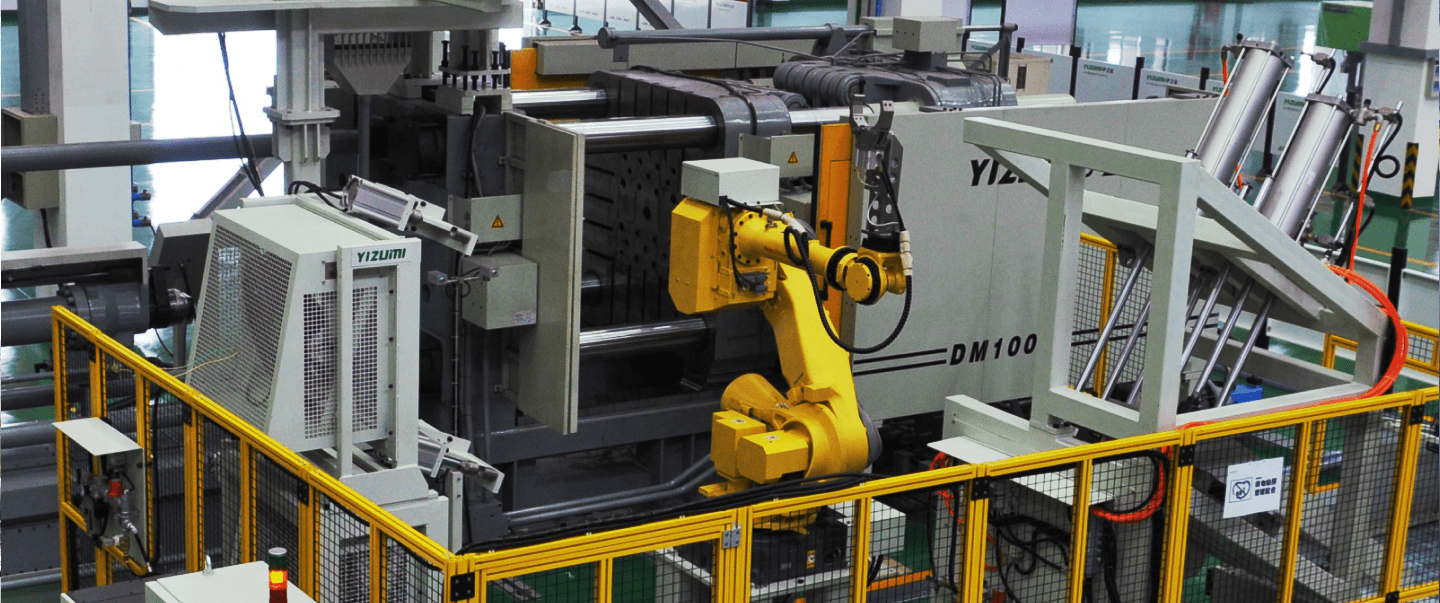

Auto extractor

Auto extractor are used to extract finished castings from the mold, as well as to place embedded elements.

- Multiple extracting modes, can apply with different moulds to make automation production.

- PLC control, with defect signal display function, make maintenance easier.

- Most of the pneumatic parts are imported, provide high durability.

- High speed and more stable motion, higher position precision.

- With rotating function of 90 and 120 degree of gripper.

- New adding protecting fence on set, with higher safety grade.

Automatic sprayer

Automatic sprayers are used to spray separation lubricants and remove metal residues from the mold

- Can be used independently or in combination with a DCM, extractor, ladler and trimming press to create a fully automatic casting cell.

- Equipped with two JS sprayers, providing a powerful and fine jet in both directions. Dispersion is particularly important in the manufacture of thin-walled castings.

- The spray time for the movable and fixed plate is set separately.

- Can perform the function of pneumatic blow-off when lifting, ensuring a clean surface of the forms.

- The volume of the supplied liquid can be adjusted.

- The lowering speed can be reduced to increase the service life of the shock absorber.

- Allows the use of two different compositions of the lubricating fluid.

- The circuit is based on a PLC, with a built-in display for displaying errors and malfunctions.

Robots for die casting cells

The use of industrial six-axis robots is beneficial in cases where, in addition to directly removing products, additional technological operations are required, such as placing embedded elements, removing gates, stacking and other operations. Along with the die-casting machine, it is the main component of the fully automatic production cell.

Robotic Spray Painting System

The system is integrated with different brands of 6-axis industrial foundry robots, such as FANUC, KUKA and ABB. The system has an IP rating and flexibly adjustable spray painting angles. The specialized profiling spray head can deliver optimal distance, angle and pressure for spray painting, reduce the usage of mold release agent, shorten the spray painting time and enhance the product quality. All equipment is under integrated control. The safe interlocking, extra safe design concepts and comprehensive testing and alarm functions can ensure the safety of equipment and working personnel.

Robotic Electrostatic Spraying System

The particles of the mold releasing agent adhere to the surface evenly, greatly increasing the first pass yield and smoothness of the product surface With the technique of terminal electrostatic discharge, the mold release agent particles are adsorbed by magnetic field lines, without point-to-point spray painting. The spray painting time is greatly shortened. The mold has no hot expansion and cold contraction effects, improving the lifespan of mold.

Robotic polishing and deburring system

Robotic polishing and deburring system it is used as part of fully automated foundry complexes to remove buisqits and other defects if necessary.

- The system is integrated with different brands of 6-axis industrial foundry robots, such as FANUC, KUKA and ABB.

- The imported low-power electric main grinding spindle, combined with a specialized aluminum cutting tool and an imported grinding head, has higher precision and better stability. Due to the variety of flashes and burrs of workpieces, the system can change the cutting tool automatically or it can be equipped with different tools.

- Equipping with a servo positioner, the system allows 360° accurate rotation of the parts and ensures that the parts are polished and deburred in all dimensions. The floating deburring device can be deflected in 360° and it can be applied to precision machining of different materials and workpieces.

- All equipment is under integrated control. The functions of safe interlock, detection and alarm are complete, ensuring the safety of equipment. In a fully-closed operating environment, the tool detection and lubrication are carried out automatically. Automatic dust emission is safe and efficient.