Start-up of automatic molding line for production of cast iron blocks and cylinder heads at NLZ, Nizhny Novgorod

Customer: Nizhny Novgorod Foundry

The project started on 07.09.2021

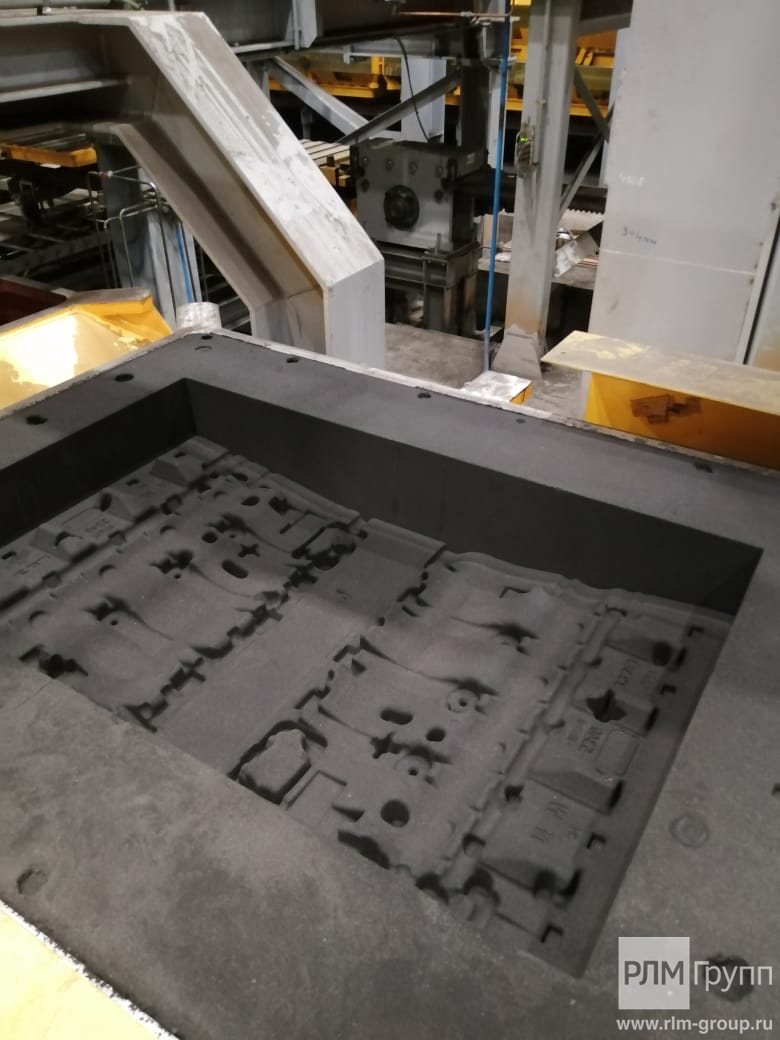

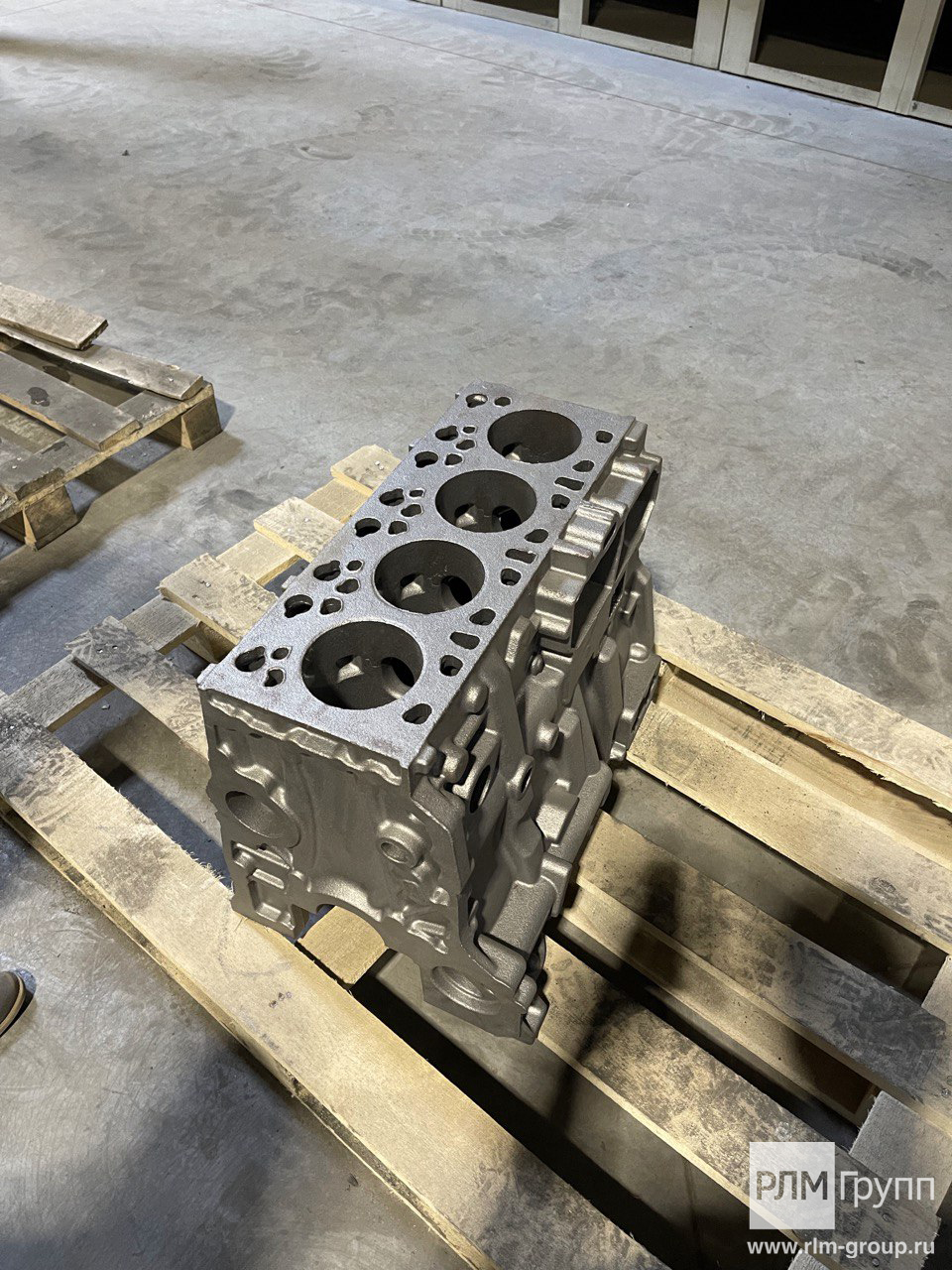

Nizhny Novgorod Foundry (NLZ, Nizhny Novgorod) has started serial production of castings on an automatic molding line using a clay sand process. The supplied line is designed for the manufacture of castings with complex structure by cast iron for the automotive industry — engine blocks and cylinder heads, flywheels, crankcases, ventilated brake discs and clutch discs, gearbox housings and transfer cases, as well as brake system components. The design capacity of the plant is over 60 thousand tons of cast iron per year. The company has created 260 high-tech jobs.

>>> Viktor Kadylkin, Director of the Automotive Components division:

«The heart of the new plant is a unique 130-meter automated molding line. Its main advantage is the mixing system, which guarantees the necessary physical and mechanical properties of the molding mixture, obtaining a clear imprint of the future casting, as well as high productivity: forming and pouring one flask takes only one minute. Modern equipment is capable of working non-stop in three shifts, ensuring a high level of quality of the castings produced».

The main characteristics of the line:

- Flask dimensions: 1.400×1.100×450/450 mm;

- Productivity: 60 complete forms per hour;

- Delivery in combination with a mixing plant with a capacity of 150 tons/hour;

- Forming process: double pressing under high pressure;

- Cooling time: 190 minutes (79 minutes in flasks and 102 minutes in metal jackets);

- Type of drives: New generation electromechanical pushers for horizontal and vertical movement of flasks in line;

- A fully automated digital line corresponding to Industry 4.0.

Nizhny Novgorod Foundry plant is deservedly one of the most modern sites in Russia for the production of cast iron for engines and allows us to meet the needs of domestic machinery building engineering and other industries in high-quality castings within the import substitution programs.