JSC MMP started the lines for production of cylinder liners

Customer: JSC Minsk Motor Plant

The project started on 20.07.2015

20.07.2015 at the JSC Minsk Motor Plant in (Stolbtsy), a fully automatic complex for the production of castings «cylinder block liners» from special grey cast iron by centrifugal casting was put in operation, the production capacity is 8.000 tons of useful castings per year.

In the complex:

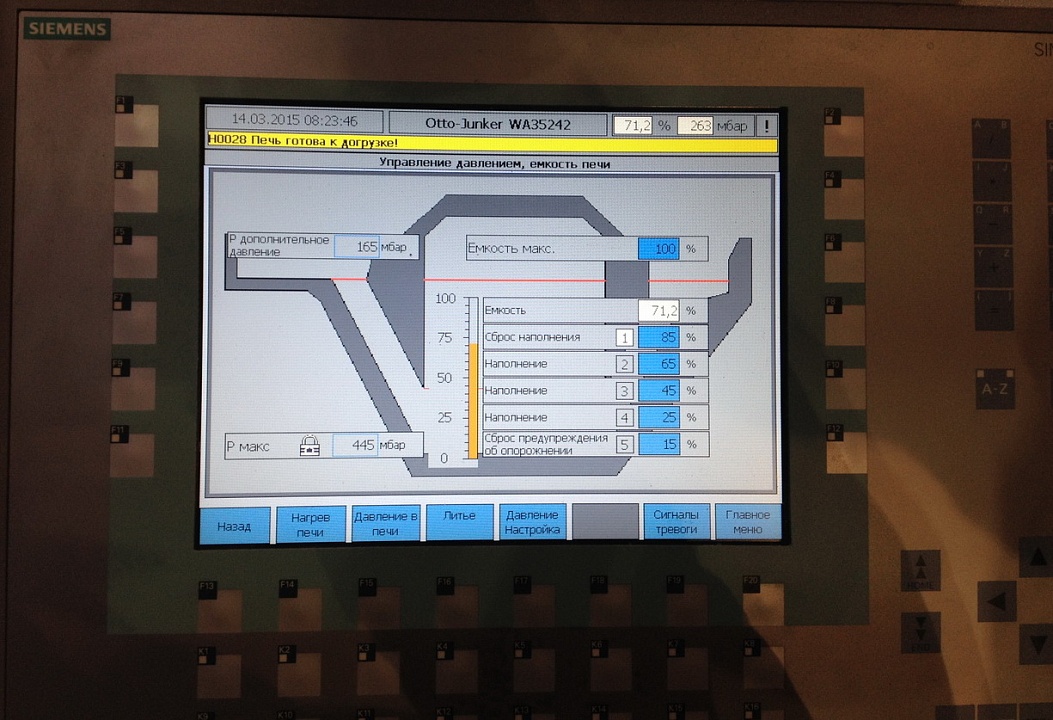

- Induction cast iron melting furnaces type 2MFTGe 1500/1200 kWt/ 250 Hz -SC Monomelt, produced by OTTO JUNKER (Germany).

- Induction heated pouring furnace of OTTO JUNKER (Germany) with stopper control system for holding and pouring of cast iron type 1 RGD Ge 2000/200 kV.

- Gas filtration system

- Shot blasting complex for castings H12×14 / 3W1E, including cartridge dust collector type CDR-12, produced by STEM (Slovenia).

- Complex for briquetting loose cast-iron chips on the basis of a horizontal feed press and hopper ArnoBrik-12.

- Two automated centrifugal casting machines type «Turntable TT10SH», produced by KÜTTNER (Germany).

- Complex of laboratory equipment for accurate spectral express analysis.

Output of the complex is 120 castings (cylinder liners) per hour.

Before commissioning of the new complex, the weight of the cylinder liner ranged from 10 to 13 kg. The new complex allowed JSC MMP to produce castings with weight up to 8.7 kg with a scrap level less than 1%, and in production of the same castings with weight 8.3-8.5 kg, to reduce scrap level less than 2%. The allowance for machining the outer surface of the cylinder liner is 1 mm per side. The allowances on the end parts of the cylinder liner are 8 mm on each side, and the end part of the cylinder liner cut off by the turning machining center from the side of the «skirt» has the shape of a truncated cone, which also reduces the metal consumption of the casting.