Complex of Mingzhi Technology’s equipment for V8 and V12 cylinder blocks has been launched at PJSC Tutaevsky Motor Plant

Customer: PJSC Tutaevsky Motor Plant

The project started on 01.11.2024

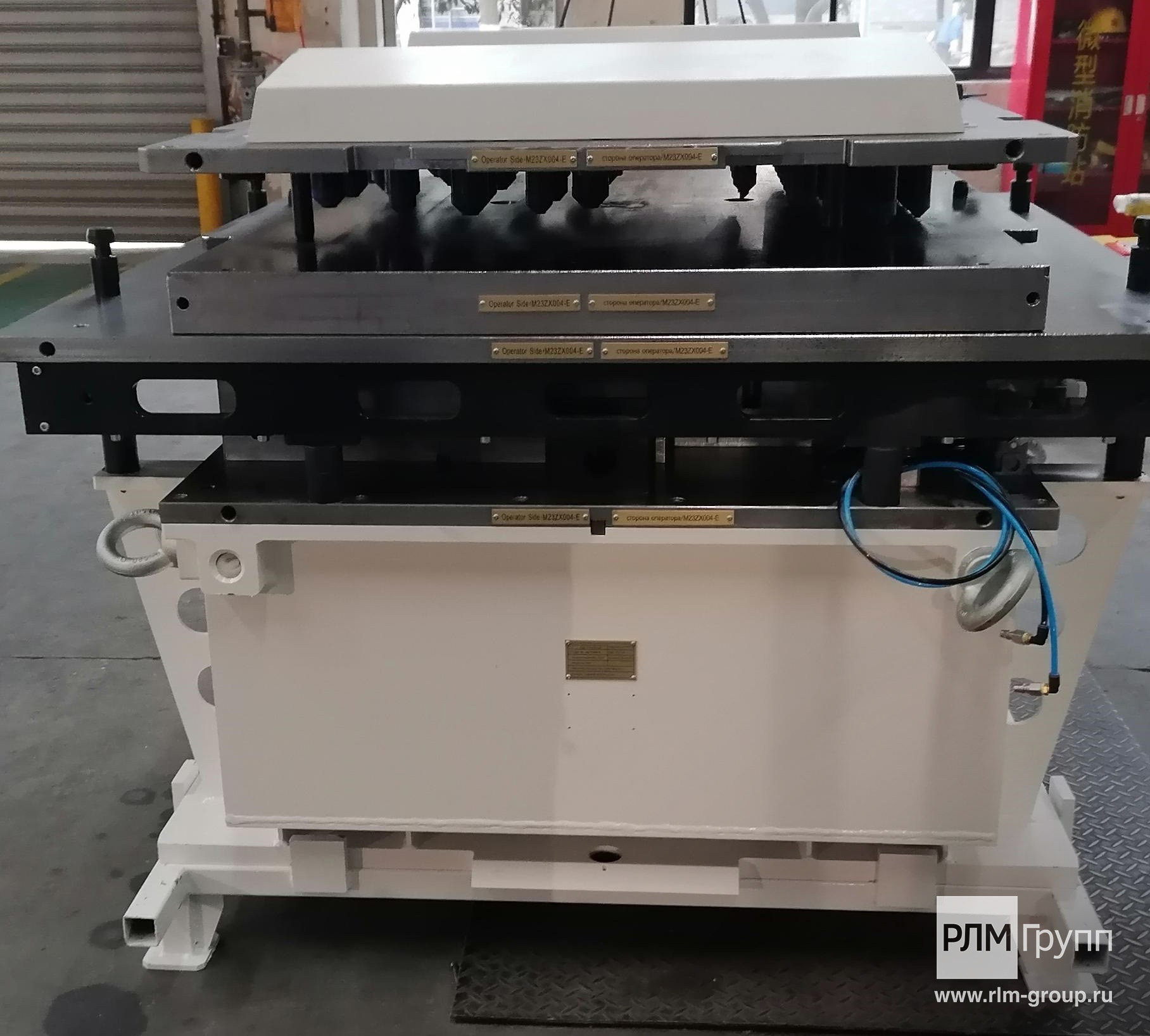

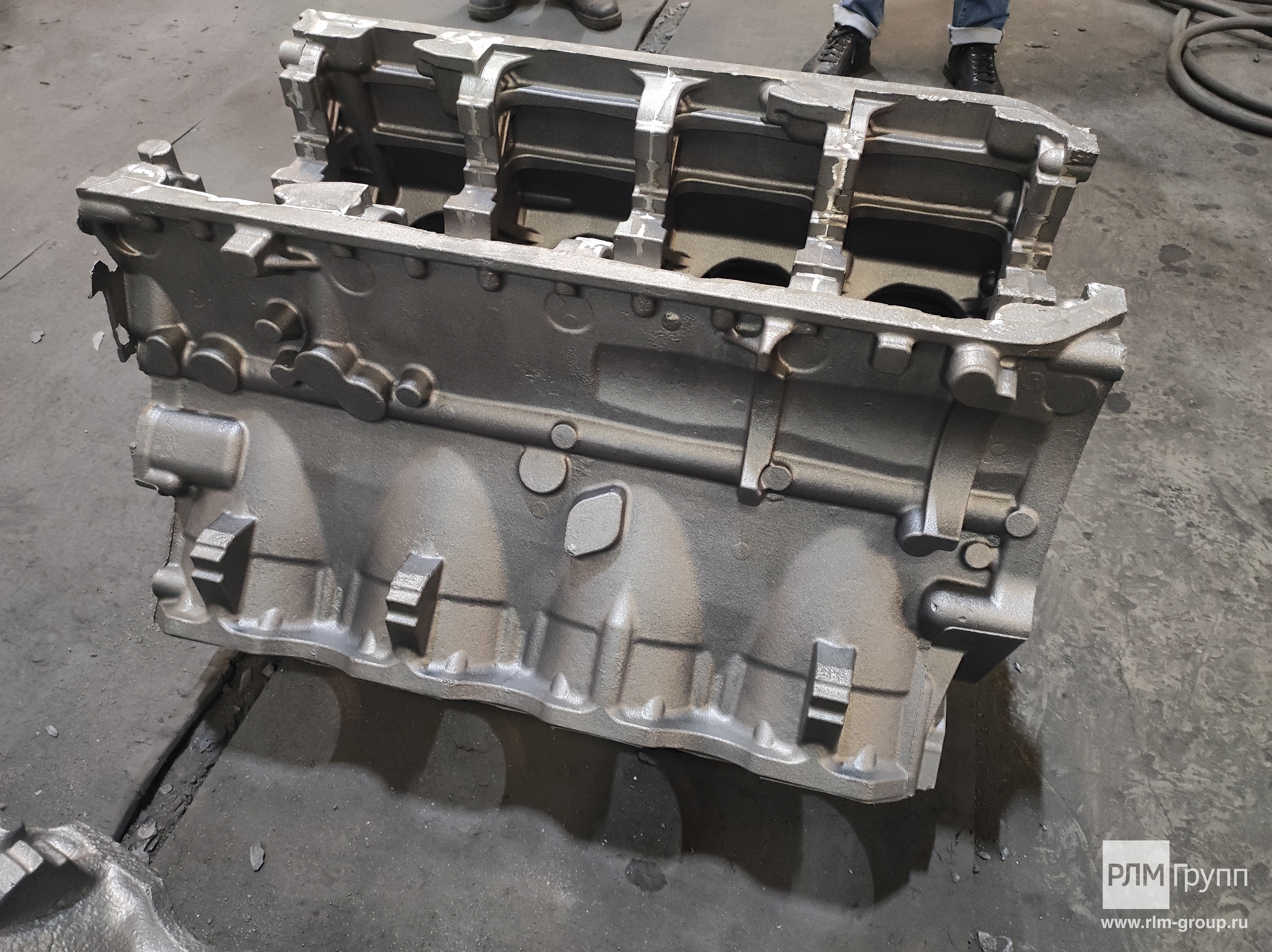

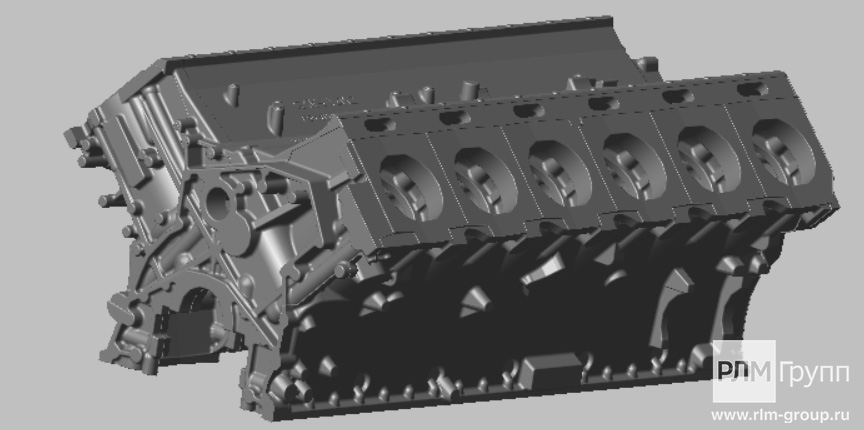

In November 2024, complex of equipment, using the new PCP technology manufactured by Mingzhi Technology for the production of core packages for the production of V8 and V12 cylinder blocks based on the MAs700 core machine (sand-shooting head capacity is 100 l) was put into operation in the cast iron foundry of PJSC Tutaevsky Motor Plant, a subsidiary of KAMAZ in Tutayev, Yaroslavl Region.

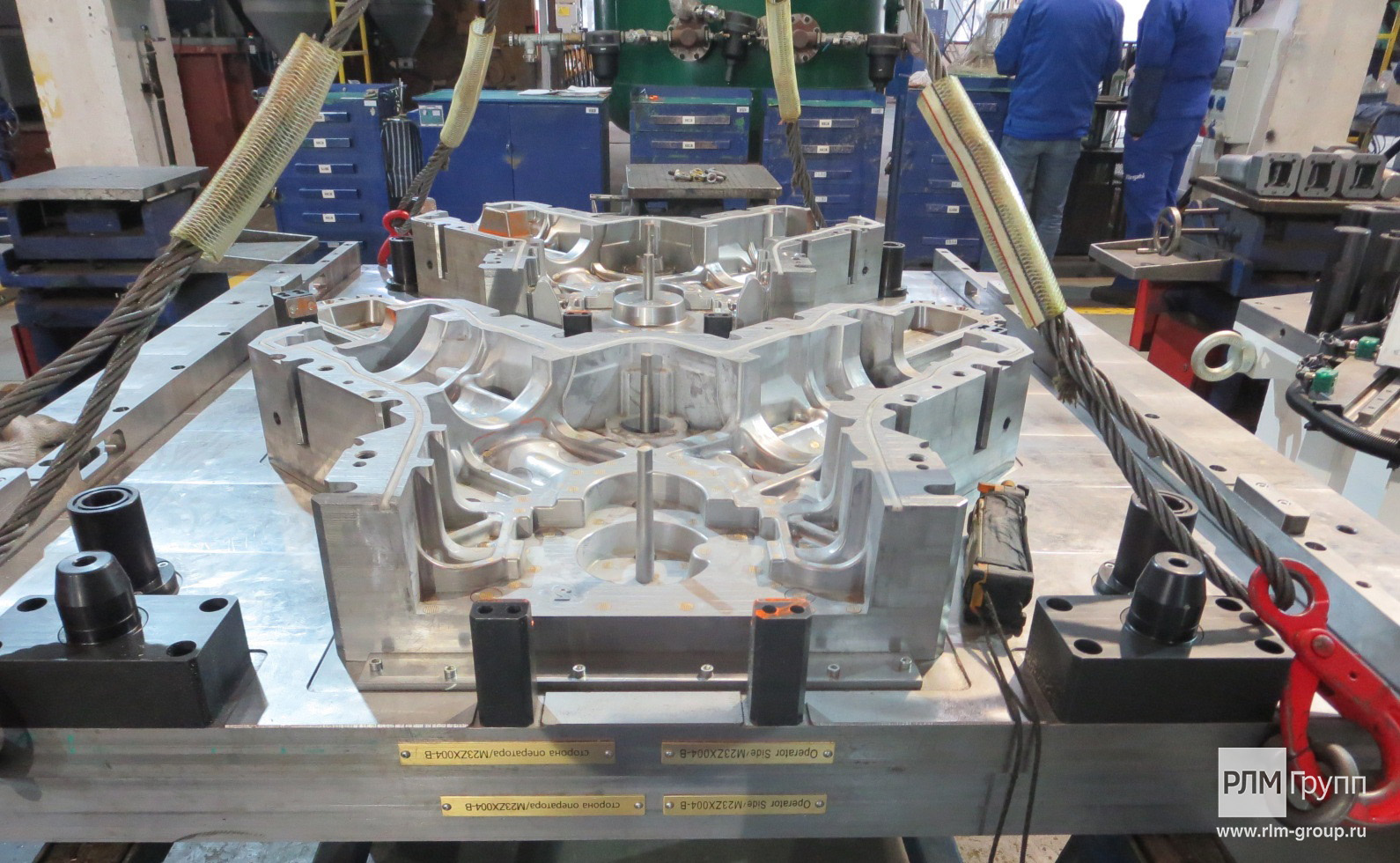

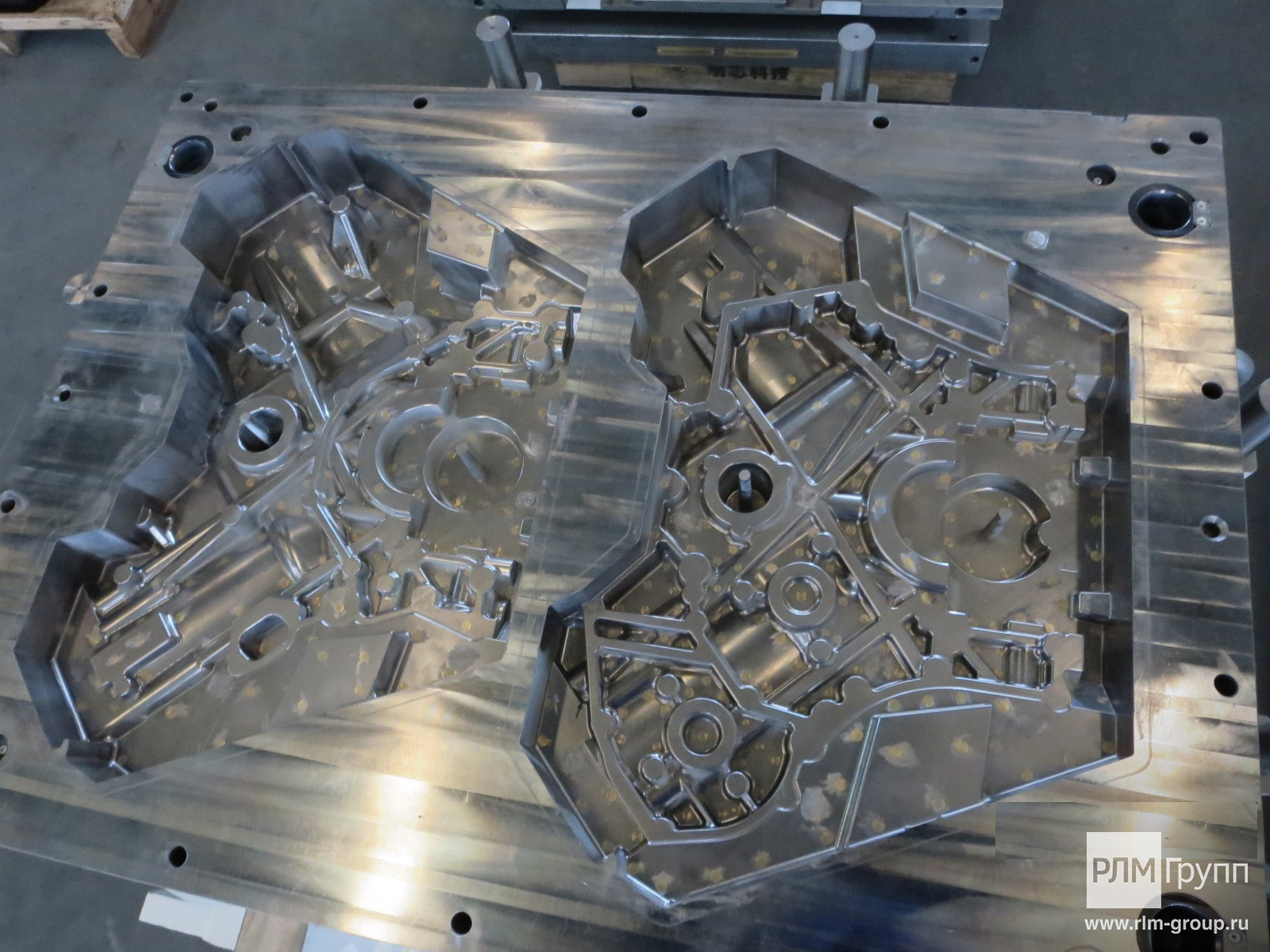

In addition to the core machine, the complex includes peripheral equipment: a sand feeding system, binder, and amine feeding system, a gas generator, a mixer for preparing core mixture, manipulators for assembling and painting of cores, a core packages painting station, a core packages drying oven, core boxes and technology for a production of least 6.000 core packages per year.

The equipment capacity is 10 core sets per hour, core production cycle time is 3 minutes, 100-125 cores are produced per shift. Time to change from one type of cores to another one takes only 10 minutes.

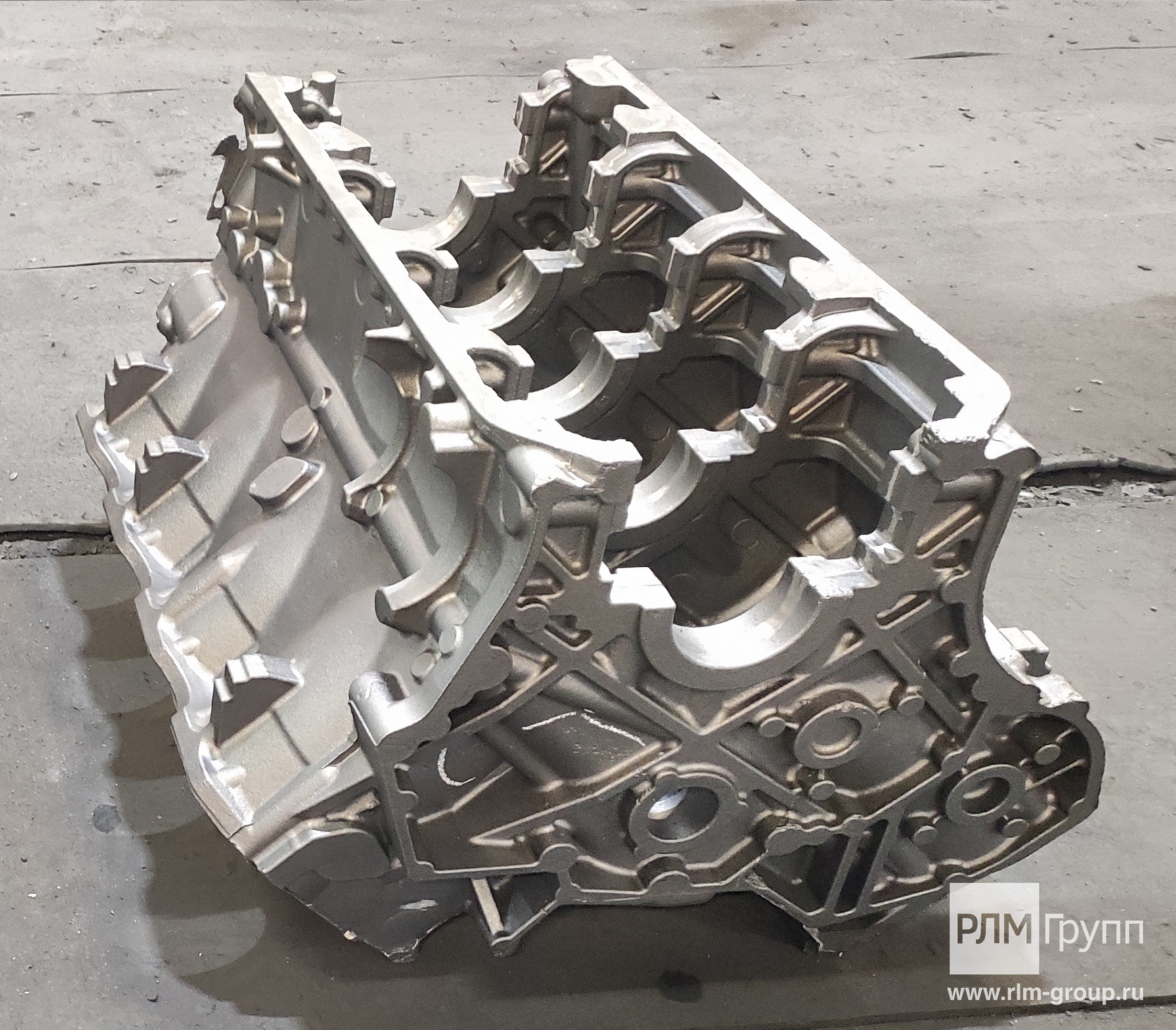

The new equipment is designed for the production of cylinder blocks using the cold-box technology — casting in coldhardening mixtures (cold-box amin process). This technology will be used to produce for 8-cylinder engines blocks manufactured by the PJSC Tutaev Motor Plant and 12-cylinder engine blocks for Yaroslavl Motor Plant.

The advantages of the new PCP technology include high quality castings, compliance with the most precise dimensions, reduced energy costs, minimization of harmful emissions, reduced labor intensity in the finishing operations of casting production and an overall improvement in the quality of work.

The new technology for manufacturing cylinder block castings allowed to customer to improve the quality of its products, reduce the cost of manufacturing castings and increase the productivity of the shop.