DELYNN

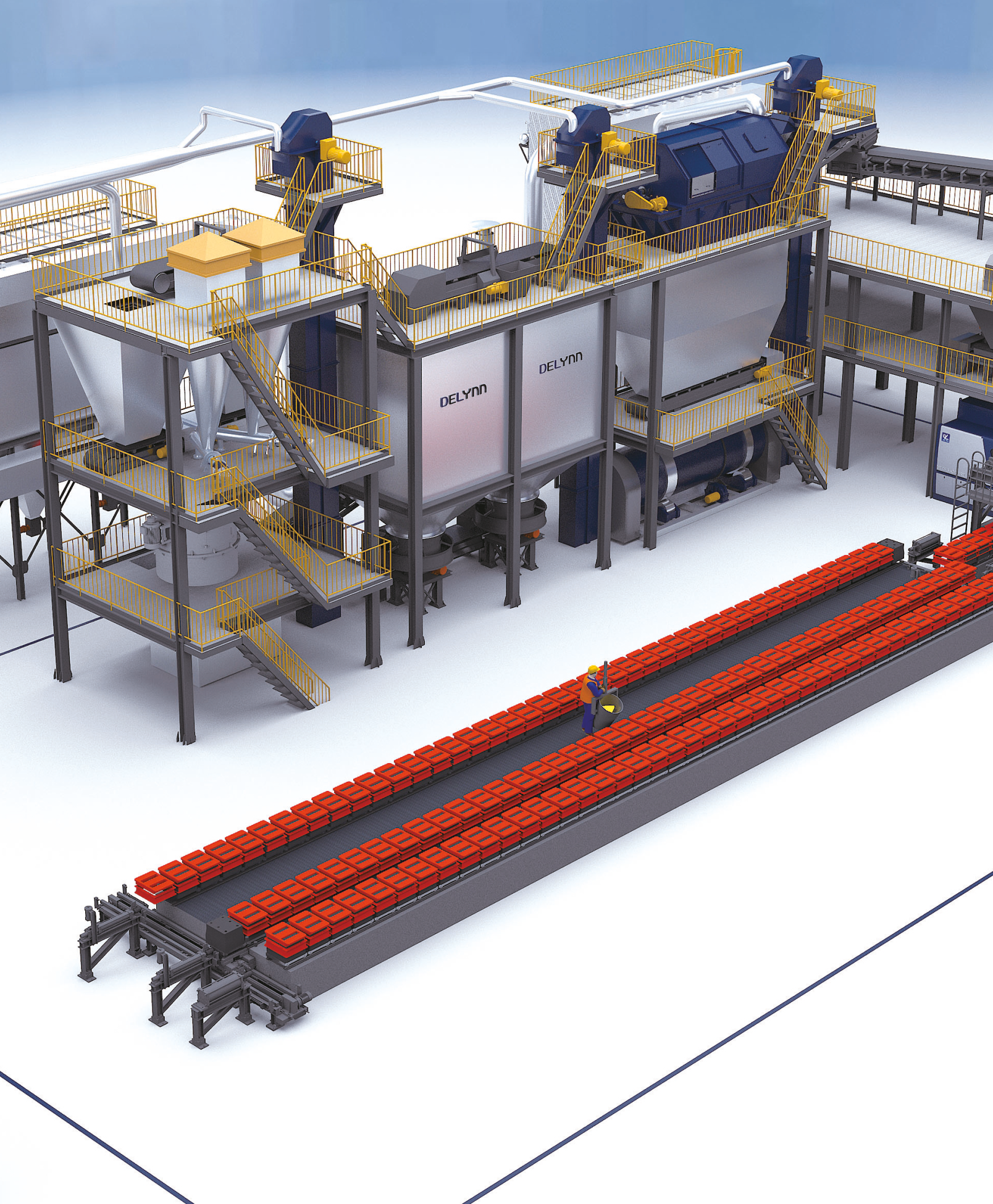

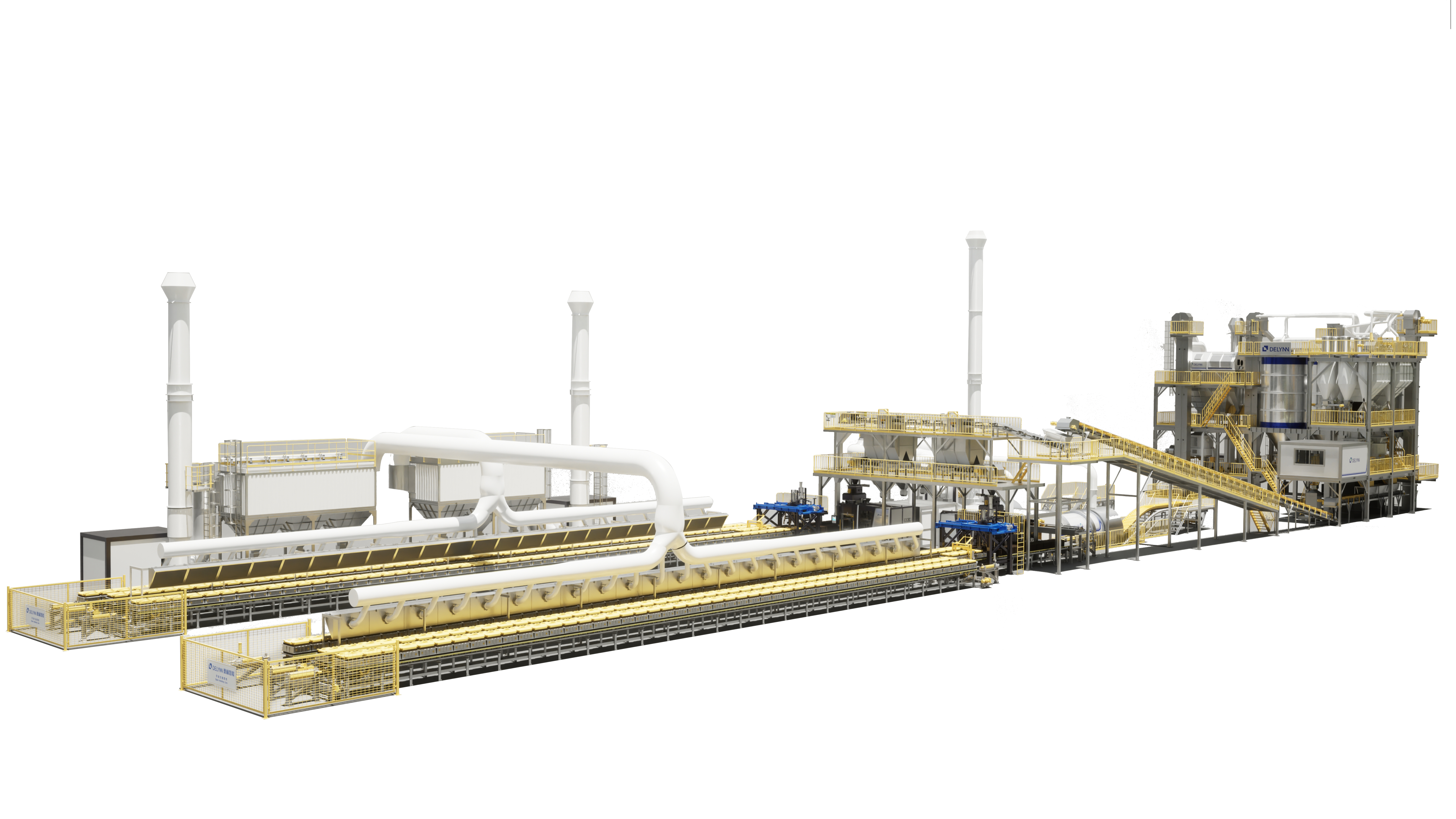

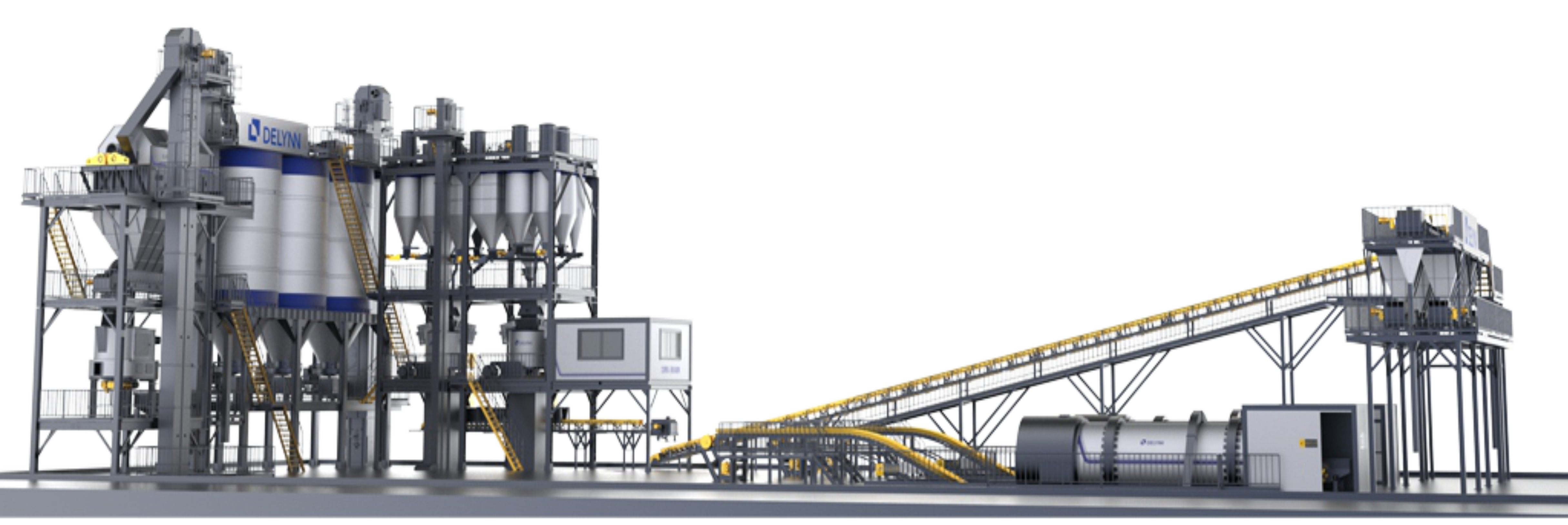

Flaskless molding lines for green sand, sand plants

Delin Intelligent, founded in 1998 in Nan’an, the hometown of plumbing in China. Our workshop floor area is 80,000 m², we have 350 employees, 80 R&D engineers. The company has always adhered to provide high-quality casting machinery, the concept of creating a first-class machinery manufacturing enterprise, and is committed to being a professional supplier of overall solutions for the entire field of casting equipment.

The company has a strong sales and technical support team, the company’s products are exported to more than 20 countries such as Russia, India, Australia, Iran, Turkey, USA, Brazil, etc. to more than 3,000 foundries. The company also has 36 domestic and foreign representative offices. For the convenience of customer service, more than 60 after-sales service points are organized around the world, which strive to provide customers with convenient, fast and comprehensive pre-sale, sales and after-sales service.

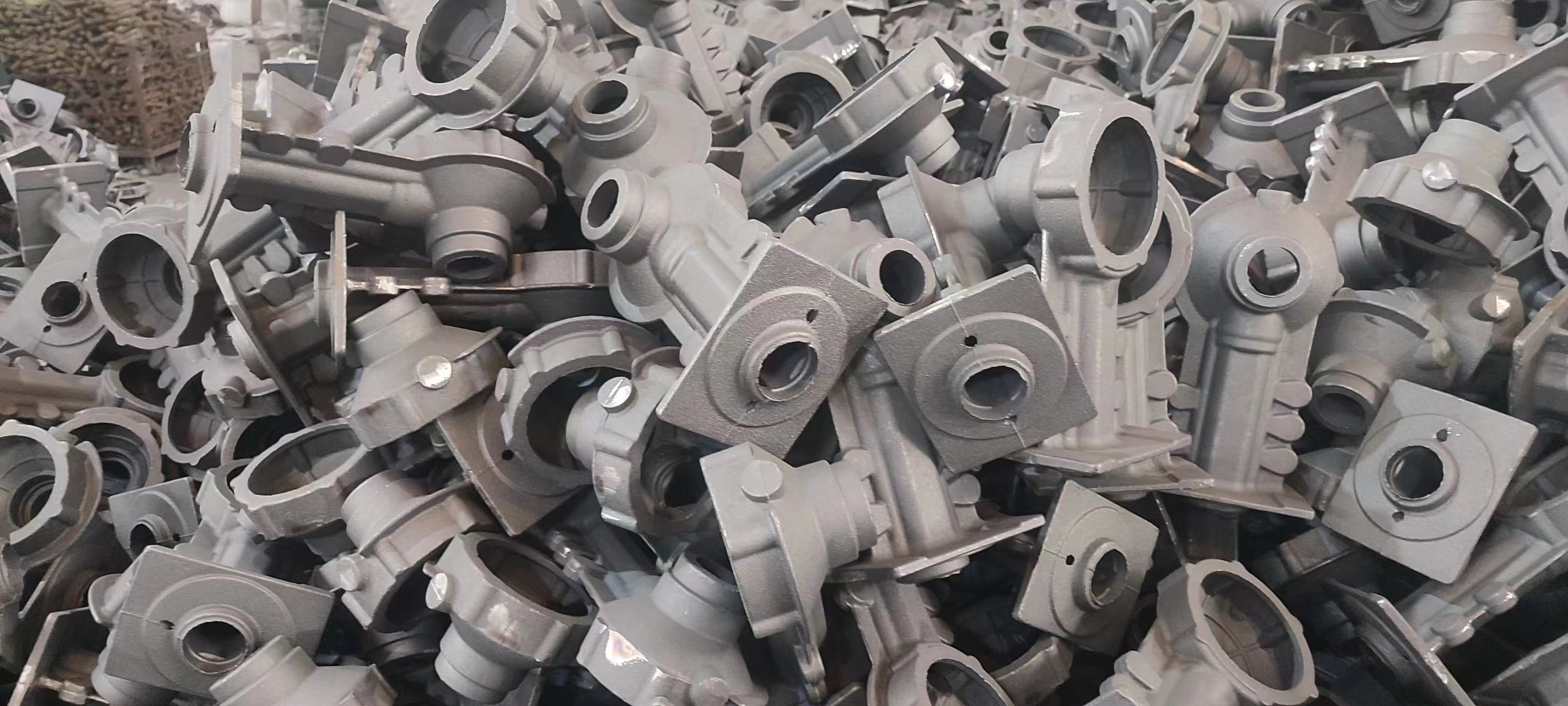

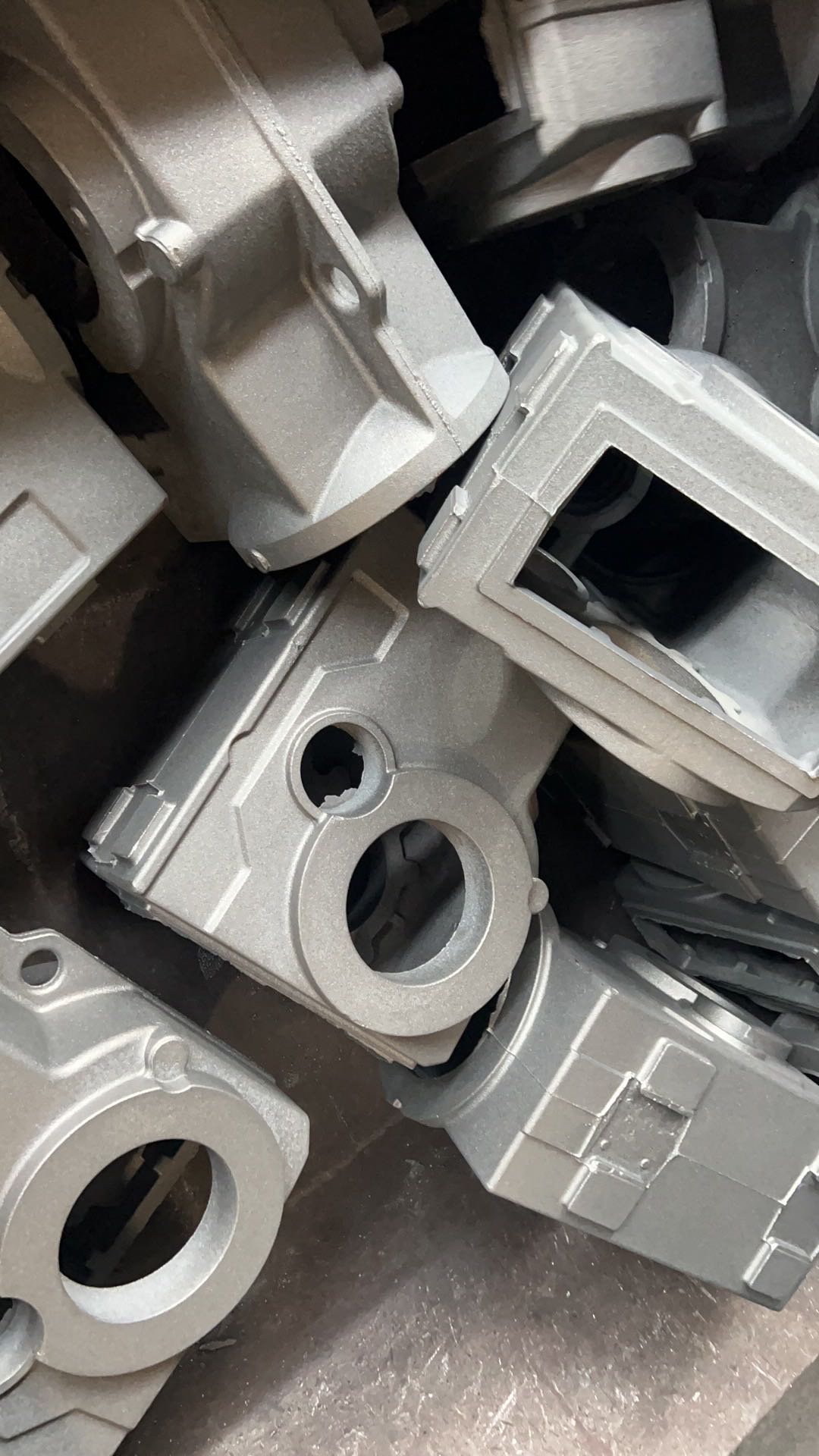

Before shipment, the equipment is assembled and tested at the DELYNN site in China. DELYNN equipment has been widely used in foundries producing automotive components, pump housings, municipal casting, etc.

DELYNN equipment features:

- DELYNN offers a complete turnkey solution: open flaskless molding line + sand plant + pouring equipment + equipment for shakeout and cooling castings;

- the maximum size of the mold on the line is 1300×1200×400/400 mm;

- maximum line capacity up to 120 molds per hour, with two molding units;

- due to the combined sand plant, steel and cast iron castings can be produced on the same molding line.

The main line of manufactured equipment:

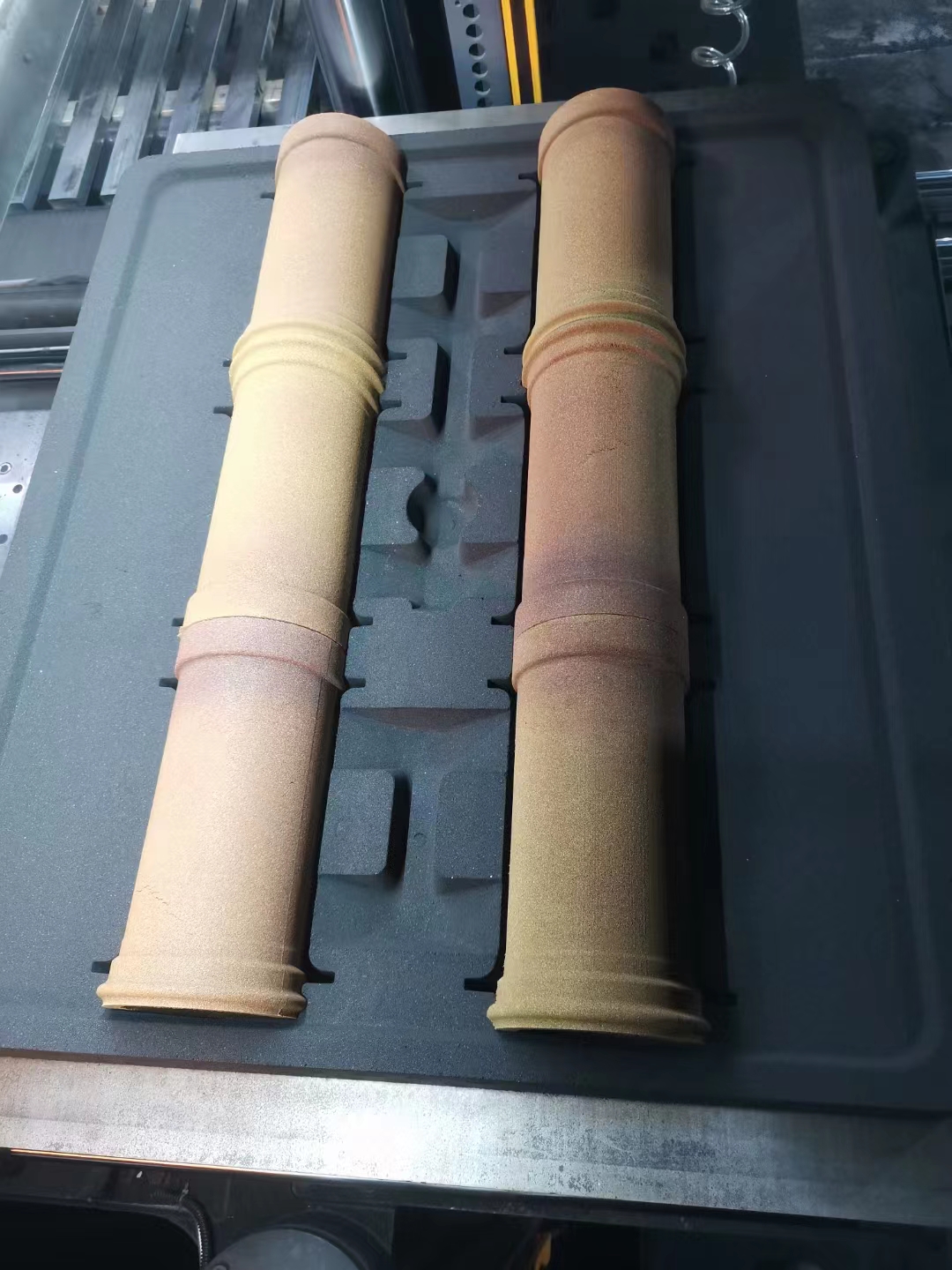

AUTOMATIC MOLDING MACHINE-UP AND DOWN SHOOTING DUAL-STATION

- Four boxes of rotating double stations, core setting and molding are performed simultaneously, and the molding speed can reach 120-150 molds/hour.

- Use up and down vertical sand blasting , the position and size of the nozzle can be adjusted, the sand shooting channel is shortened,omnidirectional sandblasting, and the sand mold yield is high.

- Equipped with automatic mold changing device, it is convenient to change molds and has high safety.

AUTOMATIC MOLDING MACHINE-UP AND DOWN SHOOTING AND SAND BOX SLIDING

- The maximum size of the sand mold can reach 1300×1400mm.

- Use up and down vertical sand blasting , the position and size of the nozzle can be adjusted, and omnidirectional sandblasting.

- Automatic box discharging, place the sand core conveniently and accurately, reduce the working intensity and have higher safety factor.

- Personalized customization of sand box size, sand mold height, etc. can be carried out according to user product requirements.

DUAL-DISC COOLER

- Homogenization of the regenerated molding sand by mixing with bipods rotating towards each other, cooling and pre-humidification by spraying water with a nozzle system.Forced cooling of returned sand, increasing moisture content of return sand and premixing,thereby improving the stability of the molding sand.

- Sand return flow control,temperature detection, water flow control.

- Sand outlet flow control and temperature detection.

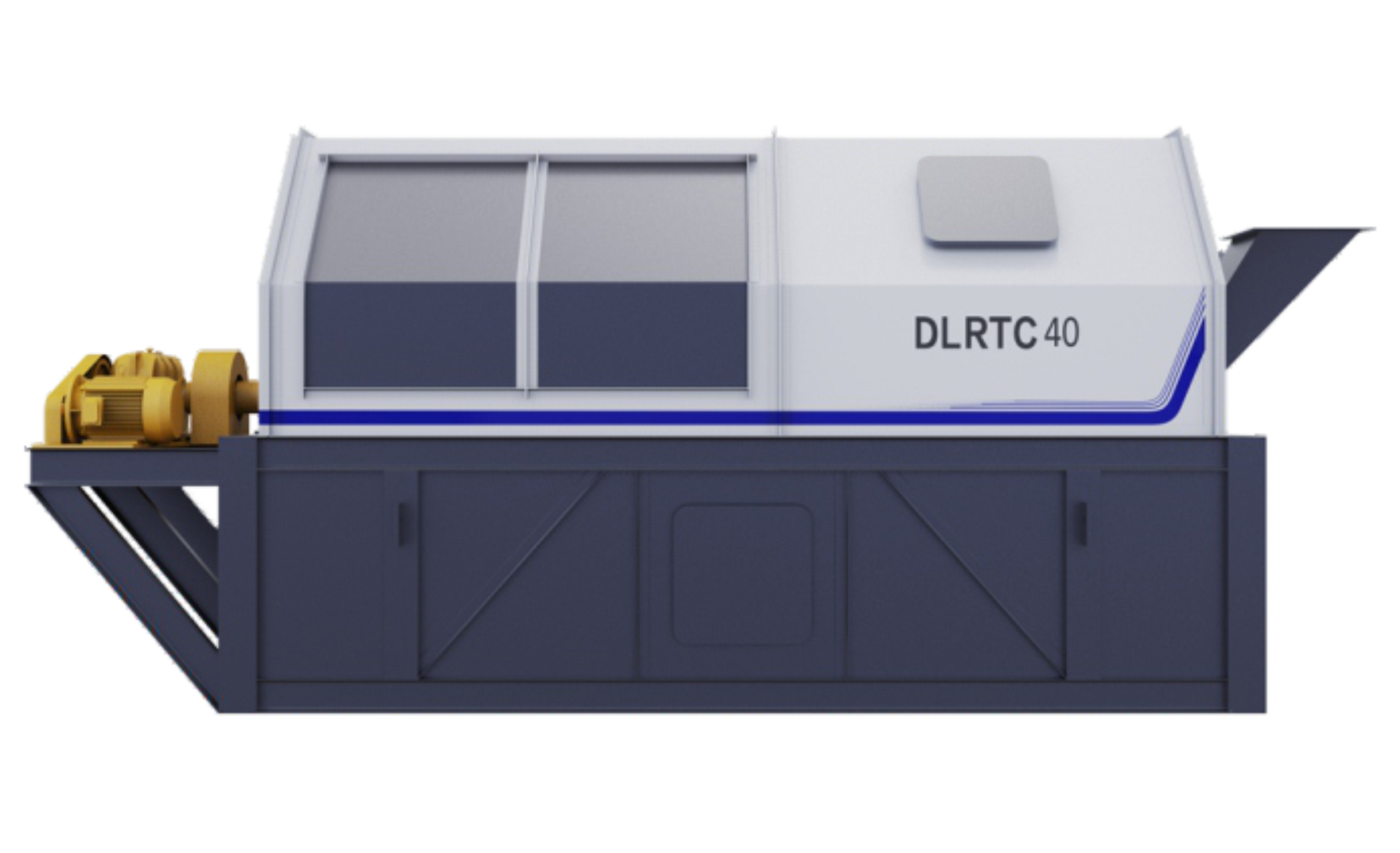

RCT TWO-LAYER COOLING ROLLOVER SIEVE

- Breaking function,the double-layer screen can play a better role in crushing, and does not increase the amount of core sand entering.

- Screening function can screen out large sand particles that cannot be broken.

- Cooling function,the higher rotation speed can achieve better stirring and surface area of the return sand, so the cooling efficiency is higher.

SINGLE LAYER SHAKEOUT COOLING DRUM

- Good rigidity, strong stability, fault-free even in low failure rate.

- The castings are separated by return sand, and the castings have low bruising rate and low noise.

- Special deflector, reduce bumps.

- Water adding system and temperature measuring system can be added according to user needs.

EFFICIENT ROTOR SAND MIXER

- Ceramic wear-resistant bottom plate and side plates are replaceable.

- YG8 welding alloy cutter head and carbide alloy surfacing material for long service life.

- The double S-shaped bottom scraper and the bottom scraper have a small gap with the side plate (no hard lumps and no delamination in sand mixing)

- Metered addition of return sand, new sand, auxiliary materials and water.

AUTOMATIC POURING MACHINE

- The pouring mode can be semi-automatic (60-80 molds/hour) and fully automatic (100-120 molds/hour).

- Tilting with the ladle mouth as the center, lifting, front and rear, and lateral movement with different sand mold heights, gate positions, and simultaneous use of pouring.

- Weight detection system; use the weight sensor to realize the detection and control of the weight of molten iron.

AIR BOX PULSE DUST COLLECTOR

Air Box Pulse Bag Type Dust Collector is a relatively advanced dust collector. It mainly consists of upper cabinet (cleaning room), middle cabinet (filter chamber room), lower cabinet (ash hopper), ash discharge valve, blowing mechanism and electrical control. When working, the dust gas passes through the diversion tank. Due to the sudden expansion of the volume, the coarse-grained dust slows down below the suspension speed due to the wind speed and loses the required suspension force. Under the action of gravity, it first falls into the ash hopper.

The subtle dust changes direction and flows upward, and is intercepted on the surface of the filter bag, while the tail gas penetrates the filter bag to the air cleaning chamber and is discharged by the fan. Due to the formation of dust layer on the surface of the filter bag, when the internal resistance increases to the set limit, the dust blowing mechanism can automatically open the pulse valve, blow air separately in turn, and enter the mouth of the bag in a spiral way, the vibration generated by expansion and contraction of the filter bag shakes off the dust hanging around the bag wall, reducing the resistance of the filter bag and returning to normal. Can fully meet the current national emission standards.

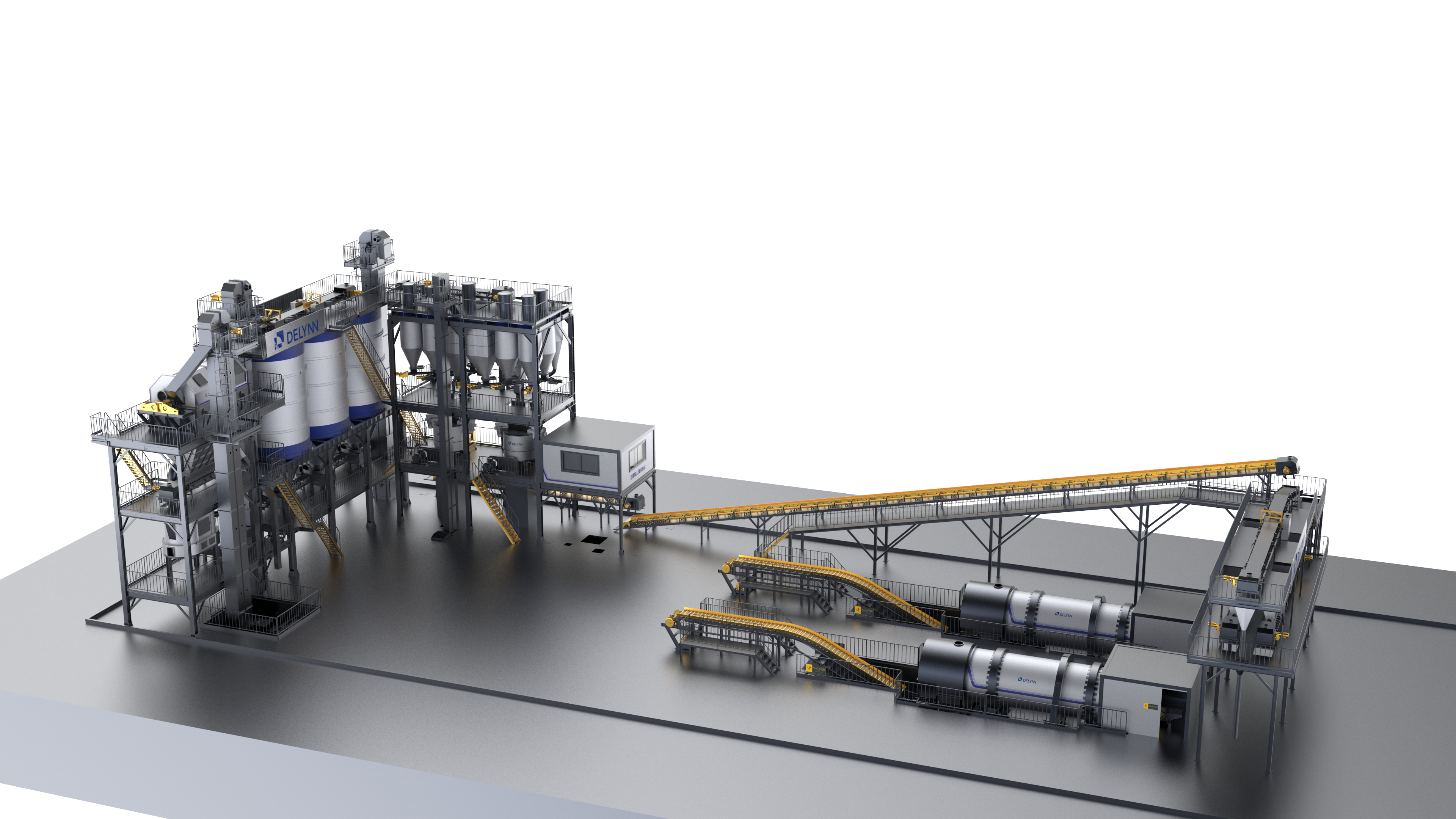

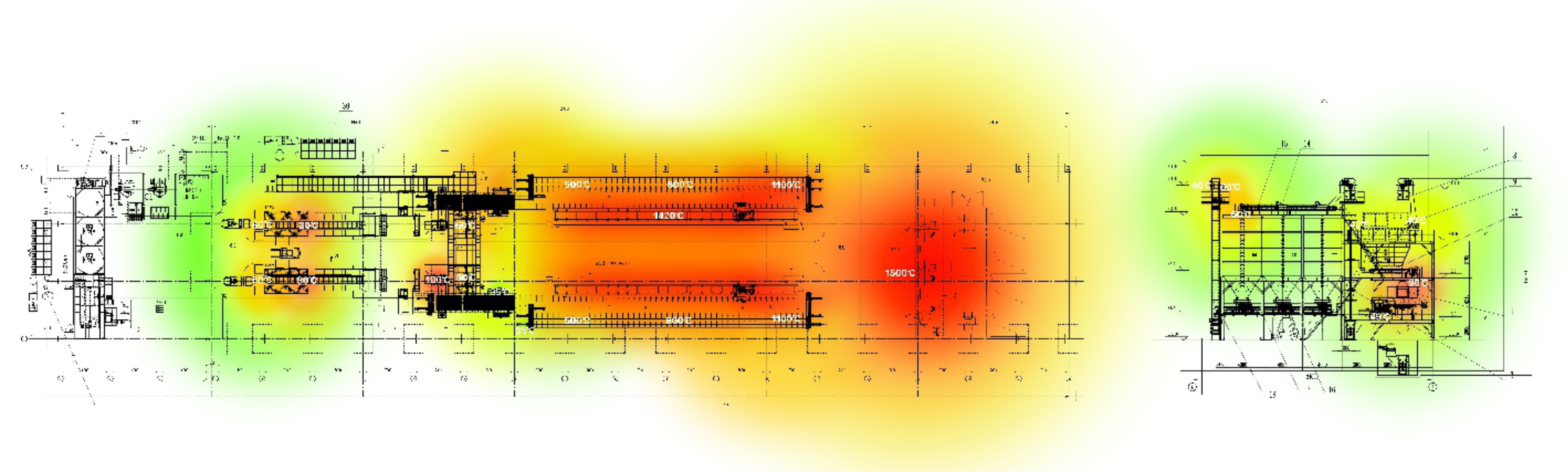

LAYOUT OF GOOD QUALITY SAND SUPPLYING LINE

- Select industrial grade magnets and have strong magnetism, which can adsorb and separate all the iron lumps, iron beans and other iron compounds in the old sand from the hot sand at high temperature.

- Equipped with a powerful cooling system, which can cool the hot sand of more than 100 degrees in a short period of time to below 50 ℃ or close to room temperature.

- It has a perfect dust removal system, so that the old sand can be free of dust pollution during the process of sand falling, transportation and mixing, and it can absorb and remove the excess dust in the old sand.

- With a complete screen structure, it can completely separate and remove the sand blocks and inclusions in the old sand.

- It has an accurate quantitative system, which can accurately weigh the weight of the added materials, and can set different proportions by changing the parameters at any time. Once the parameters are determined, the material ratio is constant.

- With a powerful conveying system, the old sand that has just been unpacked and shaken out can be quickly, smoothly and stably conveyed to the designated position through the belt and elevator, and the molding sand is conveyed to the molding position again by stirring and mixing.

- With a powerful sand mixing mechanism, the old sand, auxiliary materials and water can be fully stirred and mixed to produce qualified sand quality.

- It has a complete electronic control and monitoring system, which can accurately feedback the operation of each organization at all times, and has the functions of early warning and alarm.

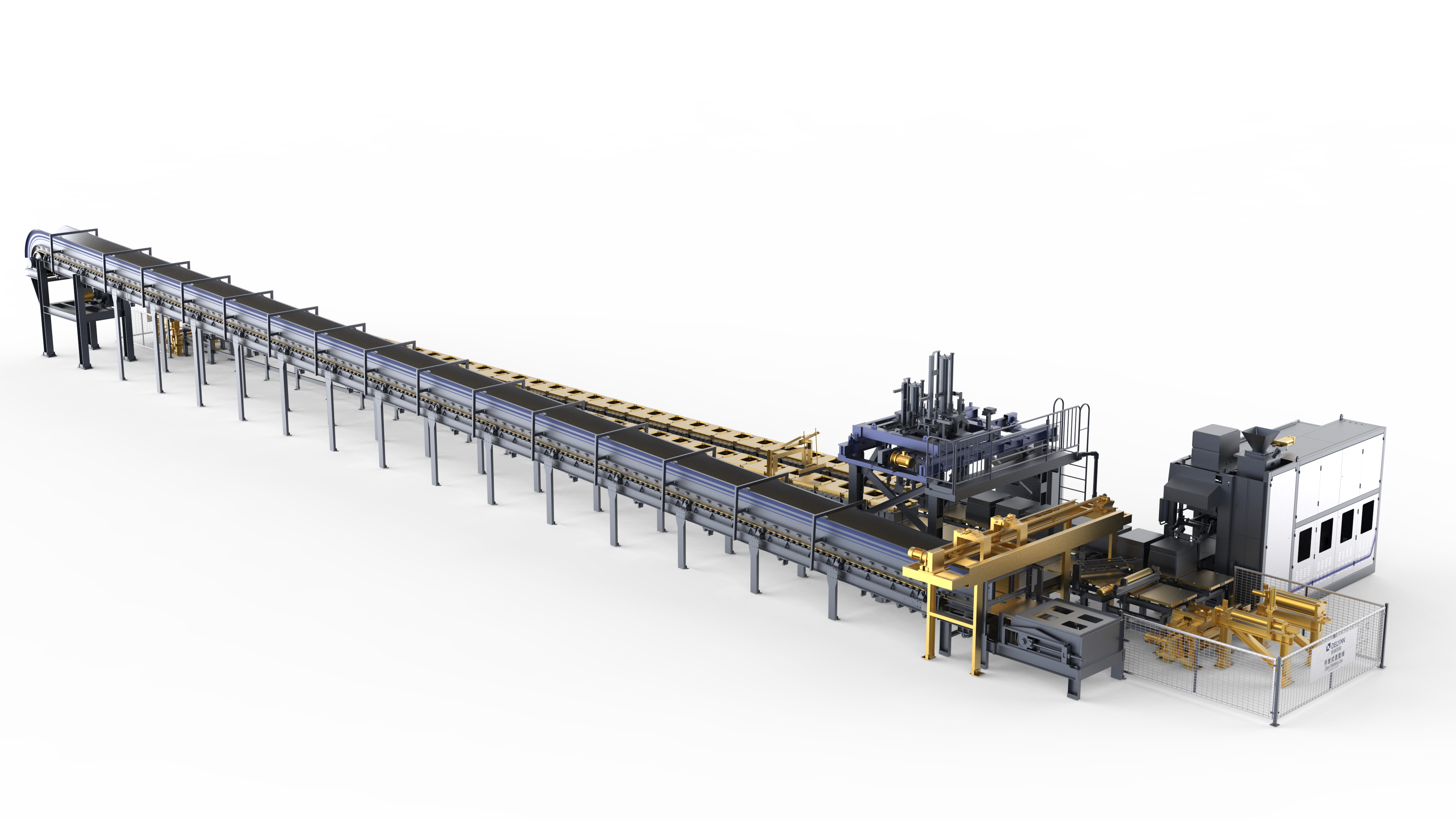

DIAGRAM OF CAST OPEN CONVEYOR LINE

- It can be customized according to customer’s requirements as per open casting line with 1 or 2 molding machines.

- Advance technology idea, reasonable processing requirements. good stability and high performance of automation.

- Decrease labor intensity, improve the working environment, reduce the waste of raw and auxiliary material, environmental-friendly.