EKVIZOL

Exotermic riser sleeves

The main activity of the company is the production of refractory products and materials for the metallurgical industry.

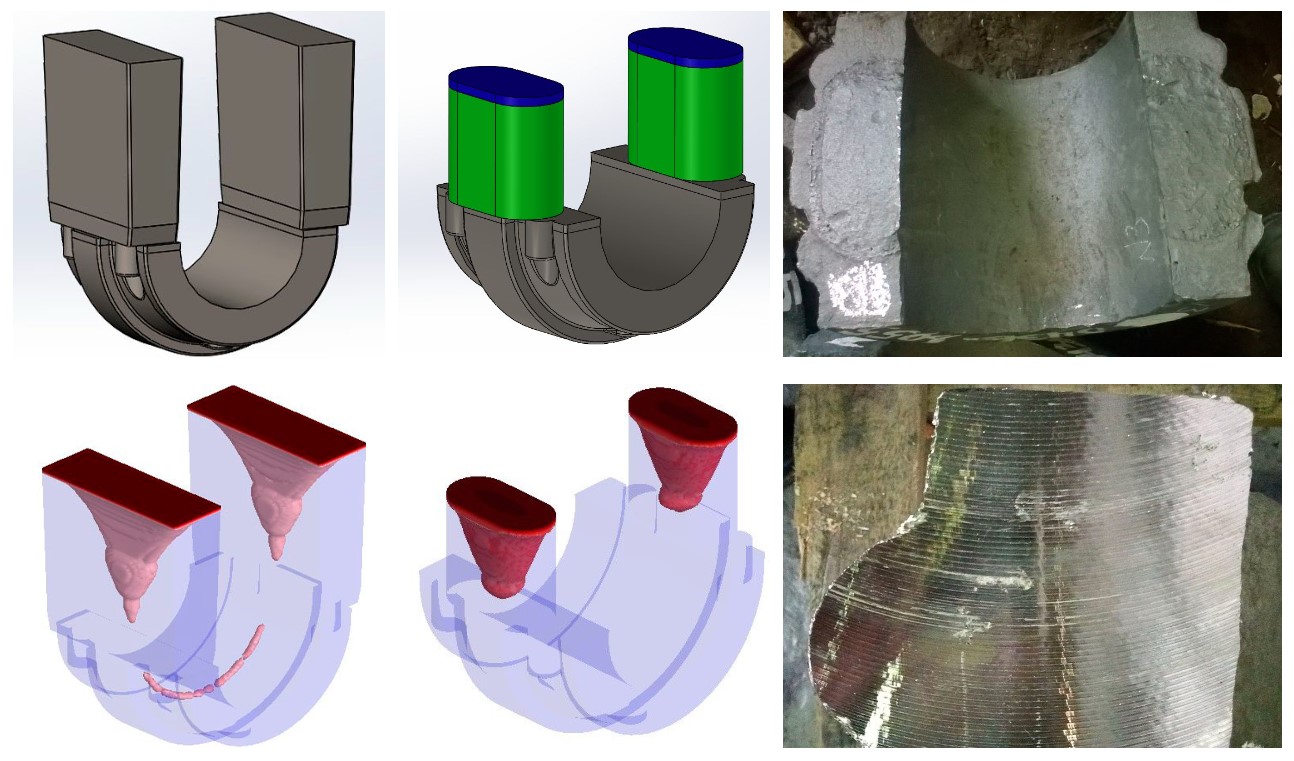

In 2018 the company began producing exothermic sleeves for foundry. The exothermic sleeves are produced on a modern automated line.

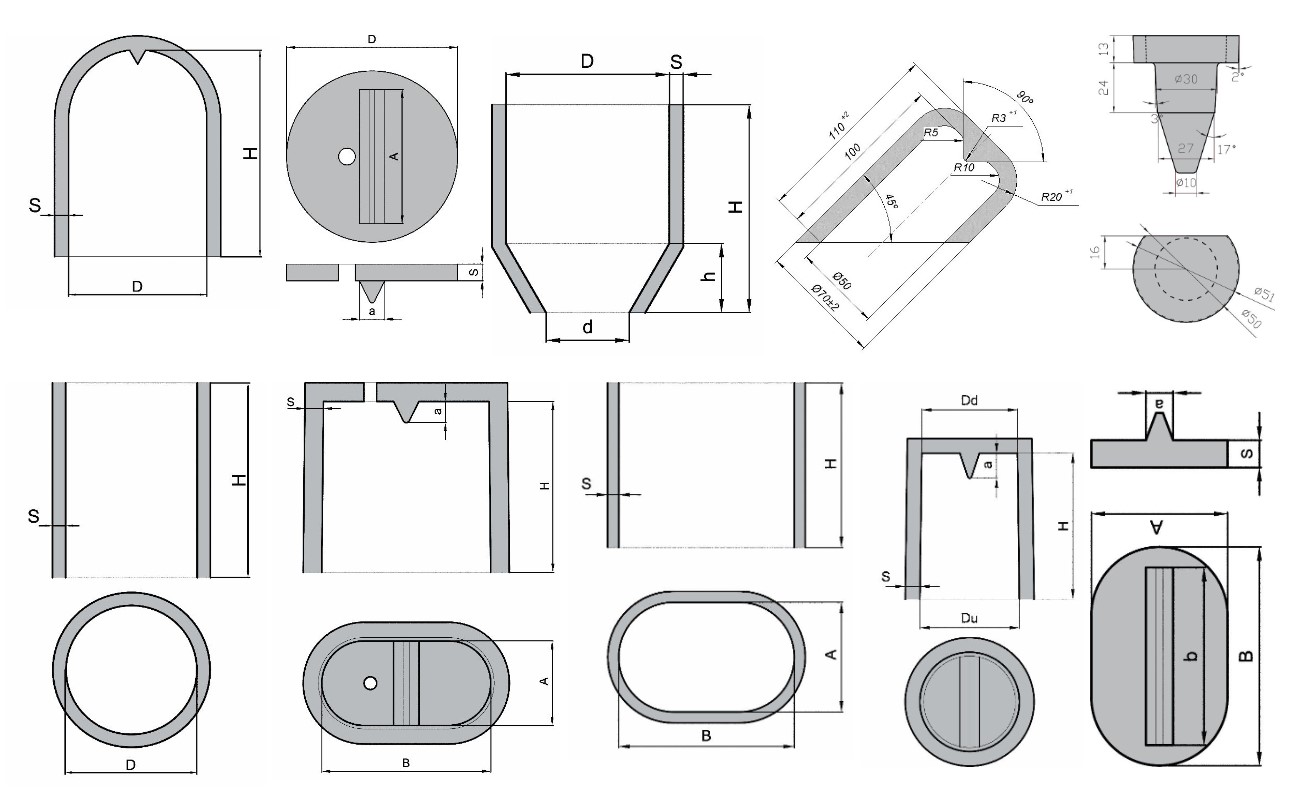

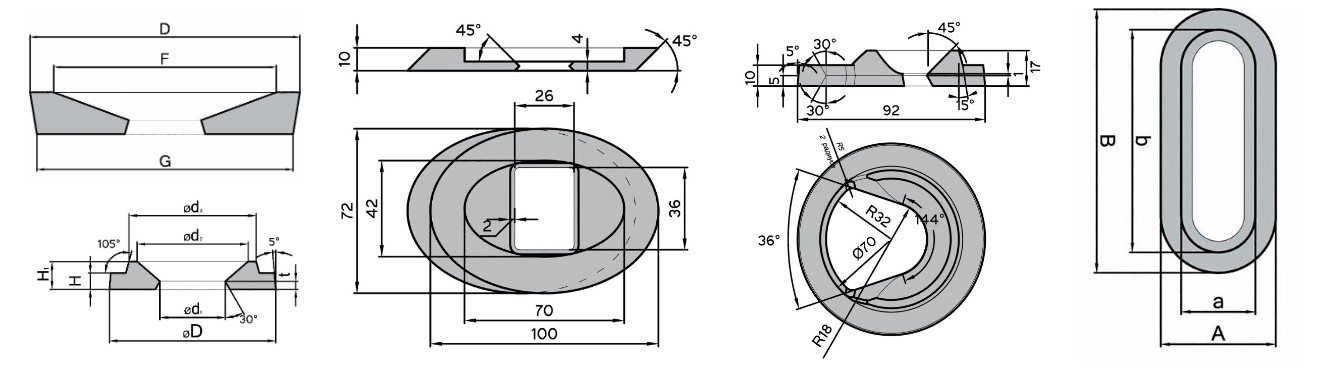

Exothermic sleeves are produced in various designs:

- domical;

- cylindrical;

- oval;

- conical;

- side-on;

- lids;

- exothermic mats;

- products according to customers drawing.

The sleeves are equipped with breaker core, which are made of hot-box or amine process.

The functions of acceptance test of raw materials, as well as the functions of quality control of products are carried out of the modern laboratory with qualified personnel of subcompany «Center for Testing and Control».

The laboratory has modern equipment and qualified personnel.

Acceptance test of raw materials for exothermic sleeves is carried out according to such parameters as:

- Humidity;

- Chemical composition («wet chemistry», X-ray fluorescence control method);

- Gas production;

- Mesh-size distribution;

- Density.

To evaluate the performance of exothermic inserts are used special control methods:

- Method for determination the maximum combustion temperature;

- Method for determination of starting combustion temperature;

- «Cube Test».

The choice of installation location, size and number of exothermic sleeves makes engineering department. For the calculation modern methods of computer modeling are used.