NANJING PUJIANG

Spherodizing and graphitising modifiers, NiMg alloys

«NANJING PUJIAN ALLOY MATERIALS CO., LTD.» was founded in 1995 with a registered capital of 20 million seventy thousand Chinese Yuan. In 2011, a new company «NANJING PUJIAN ALLOY MATERIALS CO., LTD.» (hereinafter referred to as «Puyang») was established in Nanjing Economic and Technological Development Zone with registered capital of 40 million RMB and total investment of 100 million RMB.

The company specialises in producing various series of products such as:

- graphitising modifiers for cast iron (inoculants),

- spherodizing modifiers for cast iron,

- modifying inserts for in-mould modification,

- modifiers for cast iron pipe casting, modifying wire and other.

With an annual production capacity of 50,000 tonnes. 70% of our sales are for export. In 2008, the production and sales volume exceeded 20,000 tonnes. At present, in terms of production scale, product category and export volume, our company is leading in China.

Our company has 2 3t medium frequency melting furnaces, 2 1t medium frequency melting furnaces and 4 0.5t medium frequency melting furnaces, several lines of automatic crushing and screening system and packaging system. Two analytical centres with atomic spectrum (ICP) and a complete set of equipment for chemical composition and particle size distribution analysis. This equipment is used to study the chemical composition, physical and structural properties of all products.

Since 2000, «NANJING PUJIAN ALLOY MATERIALS CO., LTD.» has passed the international authentication of IS09001: 2000, ISO14001, OHSAS 18001 and AQ/T9006-2012.

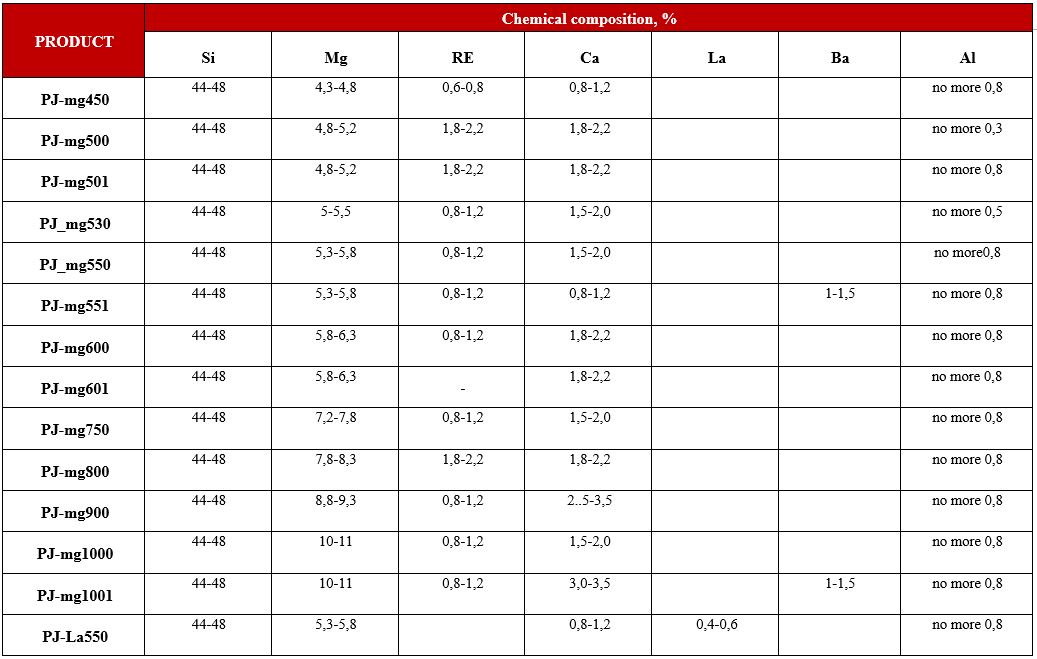

Spherodising modifiers for cast iron (A)

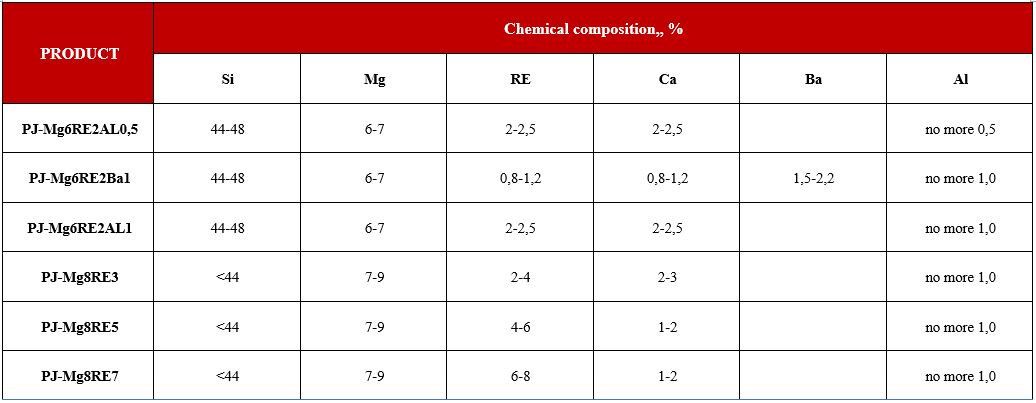

Spherodising modifiers for cast iron (B)

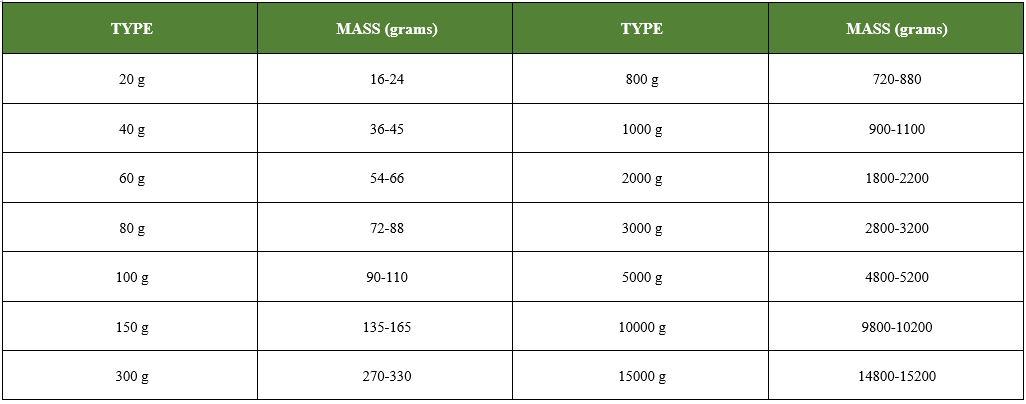

Standard size : 0.6-6 mm, 1-12 mm, 3-25 mm, 4-30 mm.

Standard packaging: 25kg bags on a pallet or 25kg bags in a 1000kg big bag.

The entire composition of each element, other special elements not mentioned above, dimensions and packaging are subject to change on request.

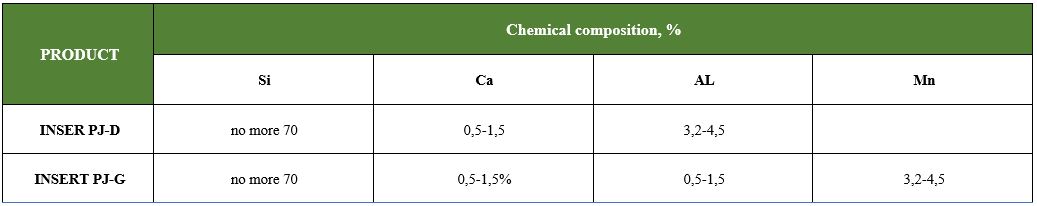

Mold Inoculant

Specification:

Standard packaging: 100kg steel drum or 1000kg big bag.

Standard packaging: 100kg steel drum or 1000kg big bag.

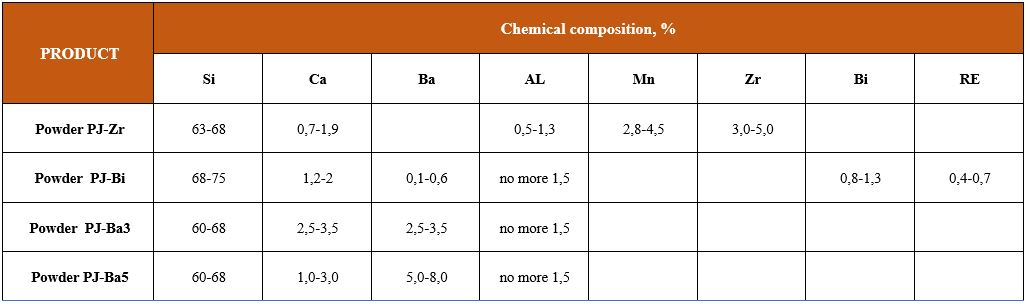

Pressing powder for the production of high-strength cast iron pipes

Standard fraction: 0-0.3 mm

Standard fraction: 0-0.3 mm

Standard packaging: 25kg bags on a pallet or 25kg bags in a 1000kg big bag.

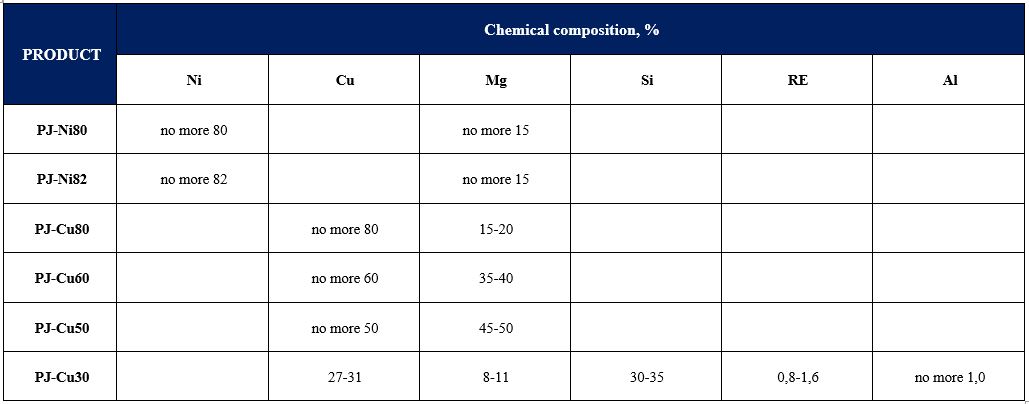

NiMg и CuMg

Standard size: 5-50 mm

Standard packaging: 100kg steel drums.

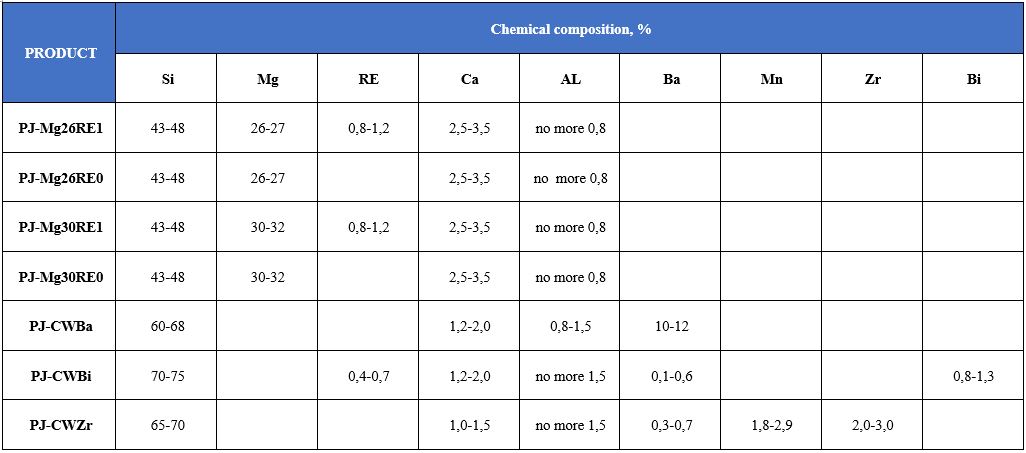

Filler powder for flux cored wire

Standard size: 0-2 mm

Standard size: 0-2 mm

Standard packaging: 25kg bags on a pallet or 25kg bags in a 1000kg big bag.

The entire composition of each element, other special elements not mentioned above, dimensions and packaging are subject to change on request.

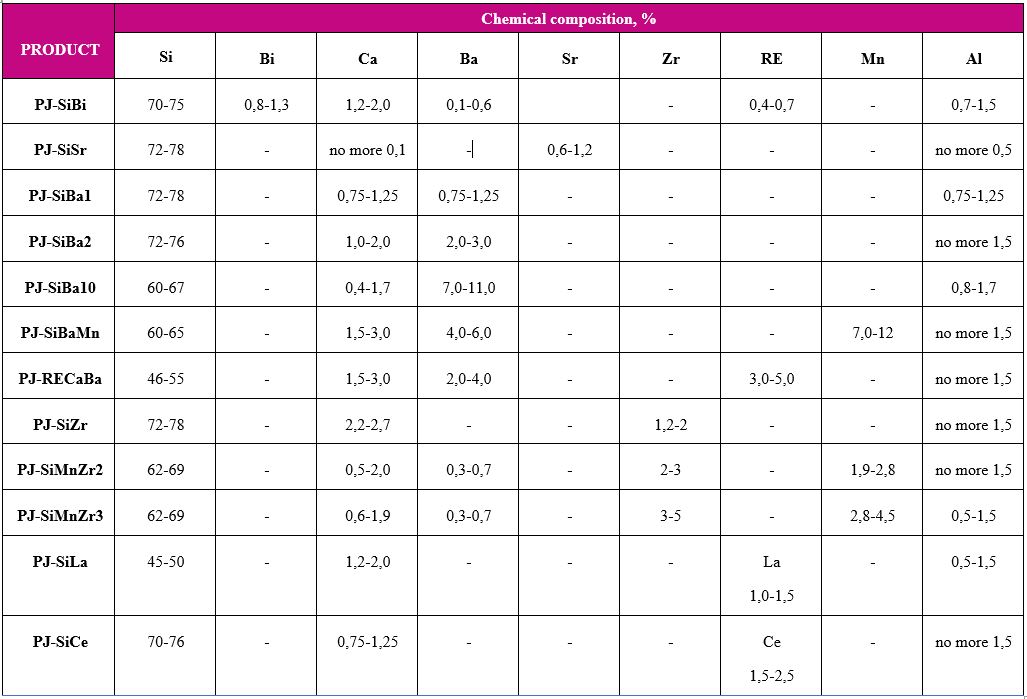

Graphitising modifiers for cast iron (Inoculants)

Standard sizes: 0.1-0.5 mm, 0.2-0.7 mm, 0.7-3 mm, 2-6 mm

Standard sizes: 0.1-0.5 mm, 0.2-0.7 mm, 0.7-3 mm, 2-6 mm

Standard packaging: 25kg bags on a pallet or 25kg bags in a 1000kg big bag.

The entire composition of each element, other special elements not mentioned above, dimensions and packaging are subject to change on request.

- Inserts

- Modifiers

- Nickel and Magnesium

- Inoculant