HIDEA

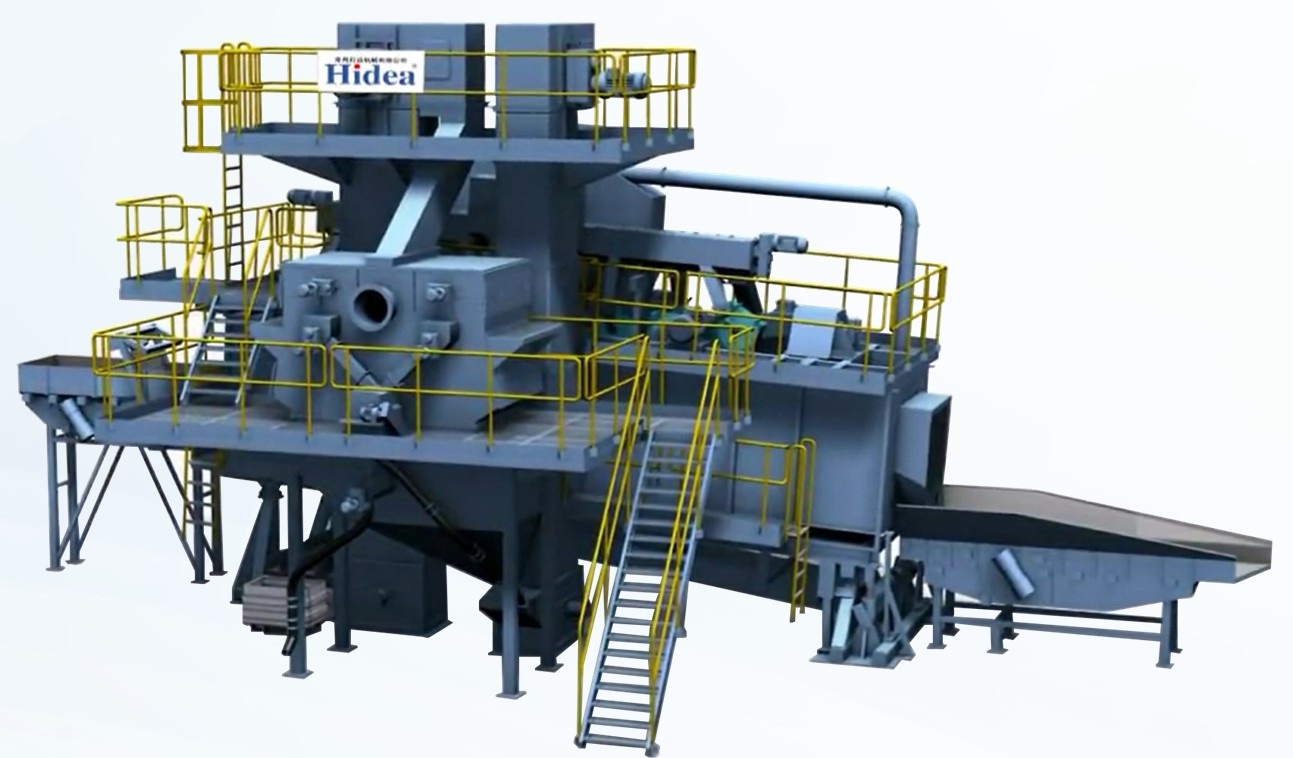

Shotblasting machines

Changzhou Hidea Machinery Co., Ltd. is an equipment supplier engaged in the design and manufacture of foundry automation engineering and providing overall solutions, also the industry leader of casting post-processing automation and the high-tech enterprise. So far, more than 30% of its products are exported abroad.

The company was founded in May of 2007. At present, there are 150 employees, including three with master’s degree and 45 with college degree or above. Main technical personal of the company have more than ten years’ experience in foundry equipment industry, also have independent and complete experience in providing solutions and equipment for enterprises in sand plant, casting surface cleaning, casting grinding, dust removing system and automatic logistics transportation system.

Hidea is focused on listening, understanding, communication and analysis of different requirements of every customer, combine it with abundant foundry industry experience and know-how to provide the customer with the most suitable, creative and economical individual solution. Hidea believes the best solution comes from sufficient communication with the customer and the company’s tireless pursuit for the best. Hidea’s creative solution is not satisfied with only help the customer solve a specific application problem, but to provide a solution which can improve the customer’s competitiveness among the whole industry.

Major products

- OH series hanger shot blast machine

- HWM series wire mesh belt shot blast machine

- SWD series batch type shot blast machine

- DM manipulator shot blast machine

- HDT continuous through type shot blast machine

- RCT roller conveyor shot blast machine

- ZD vibrating conveyor shot blast machine

- DSH double spinner hanger shot blast machine

- BB rubber belt conveyor shot blast machine

- HCT through-feed shot blast cleaning machine

- IND Drum Shot Blasting Machine

- Bag dust collector

OH series hanger shot blast machine

Application

OH series hanger shot blast machine is designed so to be more economical, so to be used for pre and final blasting of all kinds of castings, forged parts, steel parts dust remove and surface hardening, machined parts dust remove, pretreatment and hardening.

Running Mode

Castings being transported to the blast area by the hanger, according to the production requirement that one or multi hooks can be used, in every blast station that castings rotate to three different stations so to make sure the castings are cleaned thoroughly.

Equipment Feature

- Fine design, easy operation

- High efficiency and strength blast wheel, big shot volume, easy parts replacement

- Use two level magnetic separator and multi-level ventilation separator combination, castings cleaner, dust pollution lower, dust collector load lighter, wear parts life span longer, and the sand separating rate is more than 99.99%

- Blast chamber use imported high manganese plates, have long life span

- Blast chamber door design is unique, controlled by air, labyrinth sea (three layers of seal on the top of the blast wheel chamber), guarantee no shot leak

- Equipment use full auto or half auto catenary chain conveyor system so to reduce the work intensity

- PLC full auto control, malfunction alarm (full Chinese), different kind castings cleaning time can be preset, operators only need to press the button

- Security protection system design have all things considered and are scientific

- Easy to be put in line with other machines to reach full automatism

HWM series wire mesh belt shot blast machine

Application

Wire mesh belt shot blast machine mainly used for surface shot blast and shot peening of continuous high output of small parts, thin-walled castings, thin-walled and fragile iron or aluminum alloy castings, forming parts and welding parts, especially suitable for flat castings shot blast.

Running Mode

The workpiece is conveyed to a closed shot blast chamber through wire mesh belt conveyor system, use high speed abrasive flow hit workpiece in longitudinal axis above directly, horizontal axial plane and bottom slope, clean all area of surface thoroughly, shot blast the rust layer on the workpiece, welding slag, adhering sand and scale, to obtain uniform metallic luster, in order to improve the coating quality of workpiece and the anti-corrosion effect.

Equipment Feature

- Continuous through type shot blast.

- Imported wire mesh made of high manganese steel, have long life span.

- Can be suitable for diffrent shape of workpiece.

- Simple design, high reliability.

- Easy to be integrated into the automatic production line, reduce operating cost

SWD series batch type shot blast machine

Application

SWD blast machine is used for batch forged castings rust remove and easy to be turned grey iron casting, casting steel parts, ductile castings, forged cast iron parts. When integrated with magnetic separator SWD blast machine can also be used for blast core. Even SWD blast machine is designed for batch production cleaning that due to its unique design that it can also be put as inline production with other machines.

Running Mode

SWD multi-angle swing bed can swing along the axis to 120°, which guarantee the castings to be cleaned thoroughly while being turned softly, blast wheels are located on top of the blast area, shot flow focused to blast on the castings which achieve the best utilization.

Equipment Feature

- Different kind of products can be cleaned together

- Load, unload time is short, high production capacity

- Shot flow used as best

- Blast wheel on multi-angle swing bed as the best layout

- All the castings surface are exposed thoroughly under the blast flow, castings turned softly

- Blast area is big, blast cycle time is short

- Blast area no moving parts, casting won't tie together

- Load, unload parts falling height small

- Compact structure design to save space

- All the places are easy maintenance

- Easy to put for in line production

DM manipulator shot blast machine

Application

DM manipulator shot blast machine is designed to automatically clean engine block, cylinder head, gear box and other difficult to be clean castings, can be used in line with the hanger blast machine, one for pre cleaning the other for detail cleaning so to exert the best equipment efficiency and improve the blast quality, lower the blast time, achieve the casting clean automatism.

Running Mode

DM manipulator shot blast machine is separated into single station and double station, once the castings enter into the machine’s loading area that the machine starts full automatism blast. For double station, the manipulator shot clamp the casting then turn 180°then the casting reaches the blast area, casting rotate automatically along the manipulator shot axis center, and also clean the castings according to the preset program. Then turn opposite 180°, put the cleaned castings back to the loading area, starts the new casting cleaning cycle.

Equipment Feature

- Loading and unloading fully automatically controlled

- Clamp no need for any special set up, can clamp all kinds of dimension and shape of castings and clean them

- High level design, space saving layout

- In line with all the machines to reach full automatism

- The best energy and shot usage, reduce loss

- Robot programmable design to achieve detailed cleaning on special places

HDT continuous through type shot blast machine

Application

HDT Continuous Through Type Shot Blast Machine widely used for cleaning, des-coring, and derusting of castings, at the same time the equipment can maintain high level shot blast performance regardless of production efficiency.

Running Mode

The high efficiency blast wheels are positioned in longitudinal axis directly above the flow of castings, can design different blast wheels quantities according to customer requirements. Due to the reversibility of the blast wheel rotation, make castings tumble more easy and reduce collision. The abrasive flow from longitudinal axis directly above the castings can clean all area of surface thoroughly, meanwhile equipped with high efficiency sand separation system to ensure the surface clean integration.

Equipment Feature

- Continuous blast cleaning abrasive of mixed castings including poured risers, without any manual operation.

- Position of the blast wheels directly above the flow of castings ensures optimum utilization of abrasive energy.

- Controlled throughput of castings.

- No moving components within the blasting zone, no jamming of work pieces, easy to maintain.

- With lifting devices, throughput can be adjustable.

- Easy integration production with existing production lines.

RCT roller conveyor shot blast machine

Application

RCT Roller Conveyor Shot Blast Machine is used for cleaning surface .rust and other impurities for steel plate, profiles, heat treated parts, and steel structure components, at the same time, it is also used for deburring processing, shot peening and other purposes.

Running Mode

Workpiece is conveyed to blast chamber by a roller conveyor, at the same time, heavy duty energy abrasive flow shot out by high efficiency blast wheels can be completely blast casting for its upper part, side part, and bottom part, brush cleaning and air- blow devices are arranged at the exit of shot blasting chamber to ensure the surface of workpiece more clean.

Equipment Feature

- Heavy duty effiency powerful blast wheel.

- Blast chamber and rollers inside chamber made of imported high manganese steel, have long life span, high reliability of equipment.

- In many cases, the workpiece after shot blast even can cancel the pickling process, greatly reduce the cost of rear process.

- Can make automatic production line with the front and rear process, reduce labor cost.

- The roller conveyor speed can be designed according to customer requirements.

ZD vibrating conveyor shot blast machine

Application

ZD vibrating shot blast machine is mainly used for shot blasting of small and medium size castings, risers and gating system, and integral castings without separation of risers and gating system.

Running Mode

The vibrating conveyor under the shot blasting chamber is specially designed for the continuous through of castings and scraps. There are two steps on the bed surface with different heights, which make scraps such as the risers and gating system change their posture during the shot blasting. The high speed abrasive flow cleans up the sand particles and oxide scales adhered to the surface. Two grid plates are set on the bed surface for the recovery of abrasives.

Equipment Feature

- Continuous through type shot blast, easy to be integrated into the automatic production line, so asto cancel workpiece packing turnover and reduce operation cost

- It can be used for whole mold shot blasting of flat castings

- Can be suitable for different shape of scraps

- Simple design, high reliability

- The transit velocity of workpiece is stepless adjustable

- The flow of blast wheel is stepless adjustable

DSH double spinner hanger shot blast machine

Aplication

DSH Double Spinner Hanger Shot Blast Machine is used for derusting of forgings, desanding of castings, and surface treatment of aluminum alloy parts, especially for those workpieces which are not suitable for tumbling because their shape and size.

Running Mode

The machine has two compartments, one compartment can be unloaded and reloaded while parts are blast cleaned in the other compartment. Whenever the chamber is revolving to its next position, the abrasive flow is interrupted until the chamber stops rotating. The workpiece use hanger shot blast, the hanger in shot blast compartments has automatically rotate functions, shot blast more evenly.

Equipment Feature

- Compact design, quick installation, small footprint.

- High flexibility, reliability, easy maintenance.

- Shot blast chamber use imported high manganese plates, greatly use shot blast rebound.

- Easy to achieve workpiece loading and unloading.

- Double compartments work at same time, high throughput.

- Shot blast chamber door’s design is unique to guarantee the side and top no abrasive leakage

BB rubber belt conveyor shot blast machine

Application

The BB series rubber belt conveyor shot blast machine offers favourable, convincing solutions for blast cleaning of small and medium size workpieces, such as descaling of die castings or forgings or heat-treated workpieces, deburring of stampings and so on. It will accommodate batch weights of 180kg to 1300kg.

Running Mode

Depending on the weight, size, volume, and flow rate of the castings to be cleaned, the machine can be loaded in a manual, mechanical, or automatic mode. The workpieces are then tumbled inside the blast cleaning chamber consisting of a continuous through rubber belt conveyor and lateral discs of highly wear-resistant material, the workpieces are gentle tumbling and full exposure of all surface. The abrasive containing burrs, scale, or sand drop through the perforations of the rubber belt, then recycled after separation.

Equipment Feature

- Compact design, convenient installation, small footprint

- High flexibility and reliability, easy replacement of wearing parts

- Simple design and operation, high reliability

- Automatic loading and unloading of workpieces can be realized

- High effiency shot blasting performance, high economic

HCT through-feed shot blast cleaning machine

Application

The HCT series throughfeed shot blast machine is widely used, such as removing sand and cores from castings, descaling castings and forgings, handling both mixed and single product runs, cleaning fragile castings and clusters, it can keep the blast cleaning performance at a consistently high level, regardless of any fluctuations in production rates.

Running Mode

A vibrating conveyor delivers the castings to the inlet barrel of the blast cleaning machine, which has a slight downward tilt in the direction of the workpiece flow, consists of continuous metal apron plates. When the barrel tumbls, the workpiece is also constantly tumbling and flowing forward, the abrasive flow from longitudinal axis directly above the castings can clean all area of surface thoroughly, shot blasting strength can be adjusted according to the production capacity of the workpiece.

Equipment Feature

- Continuous blast cleaning can be easy integrated into the existing production lines, reduce operating costs

- Improve product consistency

- Short transport distances

- Simplicity of design for smooth process flow

- Minimize floor space requirement

- Little or no need for manual handling of the uncleaned workpieces

IND Drum Shot Blasting Machine

Application

IND drum shot blasting machine is an ideal equipment for blast all kinds of casting which is not afraid of bump or scuffing, forging, or descale of heat treatment parts.

Running Mode

IND drum shot blasting machine is often used for small parts, through hoist loading into the drum, drum rolling at a constant speed along a direction, drum can swing angle when blasting, the workpiece being shot blasted is exposed in the shot blasting area in various postures to achieve the effect of uniform shot blasting on the workpiece surface. The shot blasting machine swings and discharges the workpiece to the on-line conveying equipment to reduce the manual turnover.

Equipment Feature

- No pit, save the foundation pit cost

- Unique drum swing principle: during shot blasting, the drum can not only rotate but also swing up and down, so the workpiece in the drum is completely stirred to achieve a uniform cleaning effect

- Thanks double bucket elevator design, reduce the height of machine, suitable for low plant

- The special drum shape can facilitate complex components, uniform surface effect

- Loading and unloading all adopt the turnover box mode, no need manual operation, easy in-line with automatic production line

Bag dust collector

Description

Hidea introduces the European market mainstream bag filter equipment, independent development of efficient, reliable, durable and economic characteristics of the dust removal equipment, rugged, beautiful and maintenance convenience.

Application

Bag filter Used in the steel industry, blast furnace, converter, electric furnace, blast furnace gas purification, dust of Sintering machine head and tail; dust of Water cement production line of kiln, the kiln inlet, vertical kiln, kiln end mills, dryers, packaging machines, library top; dust of Large-scale coal-fired boilers for thermal power plants, Heat production and supply of coal-firedboilers, Coal-fired industrial boiler; Coking, CDQ dust; dust of Ferroalloy, calcium carbide; dust of Chemical production; ceramic production; Food, feed processing; dust of Port transportation, food storage; dust of Waste incineration, hazardous waste, medical waste incineration; The industry workshop for labor protection in small units.

Equipment Feature

- Hidea introduces the European market mainstream bag filter equipment, independent development of efficient, reliable, durable and economic characteristics of the dust removal equipment, rugged, beautiful and maintenance convenience

- Dust collector body with the structure of the flat bag, compact, space-saving design, and size compared to traditional bag filter about 30-40%

- Downward movement of the principle of design, and dust flow direction and the wind direction, the dust bag and dust treat-ment is more effective

- Bag offline blowback technology to clean up better, offline cleaning bag number ratio

Powder layer control blowback control technology, so that the dust emission concentration to less than 5mg/Nm3 (national emission standards 50mg/Nm3 - Domestic dust to clean up the dust attached to the cloth bag on a pulse-jet cleaning, Hidea dust powder layer blowback blower control attached to the bag, clear blow low pressure, long life cloth bags, and equipment costs are significantly reduced

- Obvious energy savings

- Special dust indoor cooling methods, greatly expanded the scope of application

- Use the circlip tensioner body, to facilitate assembly and disassembly toi; special structure convenient to check the bag to drain the gray of the failure phenomenon