STEM

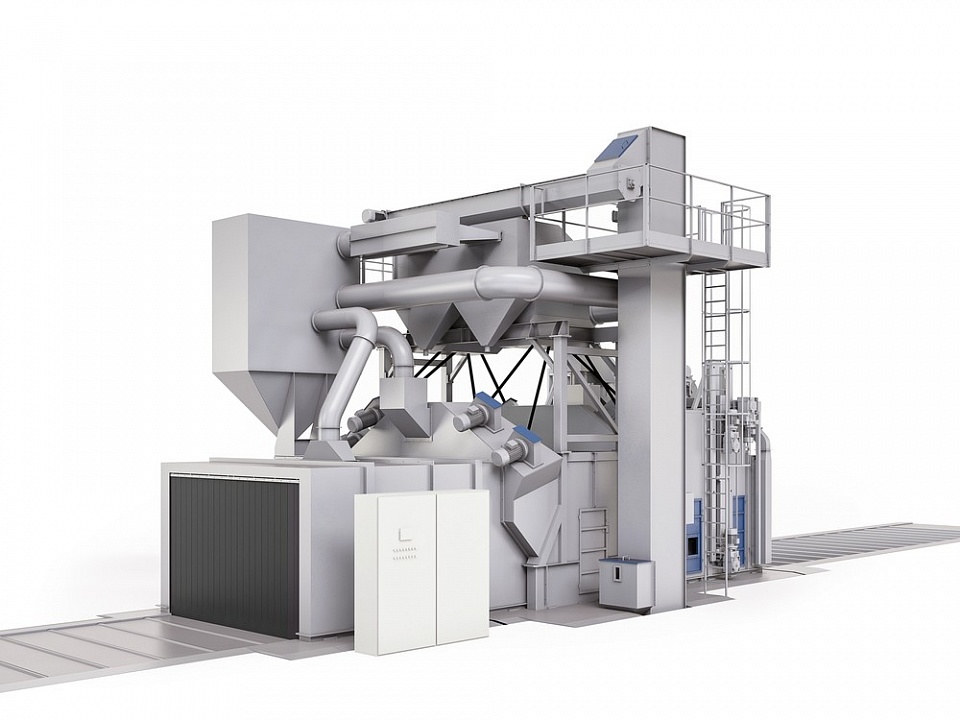

Since 1989 STEM has been specializing in the development and manufacture of shot blasting machines for surface treatment (shotblasting, matting, shot peening, stress peening, roughening, etc.)

The main production of STEM is based in Nova Gorica (Slovenia), where we design and produce our shotblasting machines. In addition to having its head office and production in Nova Gorica, STEM has two more production plants; the facility in Tolmin, where smaller standard machines are produced, and the one in Čakovec (Croatia), where machines of largest dimensions are produced.

The guiding principle of company STEM is continuous development pursuing the technical and technological market demands in order to achieve the optimum quality of treated surfaces along with rational power consumption and the amount of investment.

With over 1200 references worldwide, STEM produces:

- Plates and profiles shotblasting machines type «PAP»

- Pipes shotblasting machines type «PIP»

- Turntable shotblasting machines type «T»

- Tunnel overhead rail shotblasting machines type «TOR»

- Shotblasting chambers type «KOM»

- Hook shotblasting machines type «H»

- Tumble belt shotblasting machines type «B»

- Сontinuous hook shotblasting machines type «CH»

- Mesh conveyor shotblasting machines type «MC»

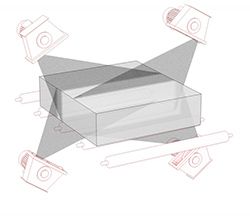

Plates and profiles shotblasting machines type «PAP»

“PAP” series shotblasting machines are designed for continuous blasting of plates and profiles, and also welded constructions. Special attention has been paid to the positioning of turbines that provide the optimum efficiency and uniform cleaning of work pieces.

Plates or profiles are loaded onto an input roller conveyor that transports work pieces through the tunnel part of the machine. On the outer brim of the tunnel’s shotblasting part, there are turbines that provide optimum cleaning of work pieces from the top and bottom side. Work pieces go on through the chamber for removing the shotblasting agent off the top surface, finally reaching the output roller conveyor.

Shotblasting machines of “PAP” series may be upgraded into an automatic line for the application of primer paint.

Such line consists of:

- hydraulic loading device

- input roller conveyor

- pre-drying chamber

- shotblasting machine

- automatic painting chamber

- drying chamber

- paint drying conveyor

- output roller conveyor

- hydraulic unloading device

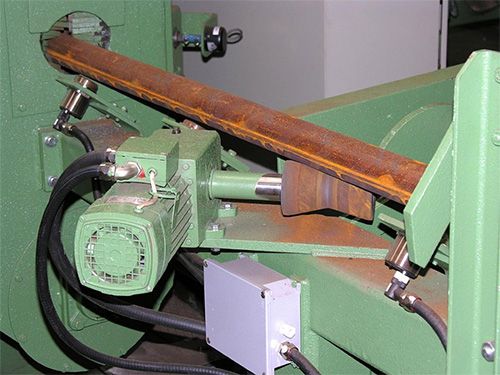

Pipes shotblasting machines type «PIP»

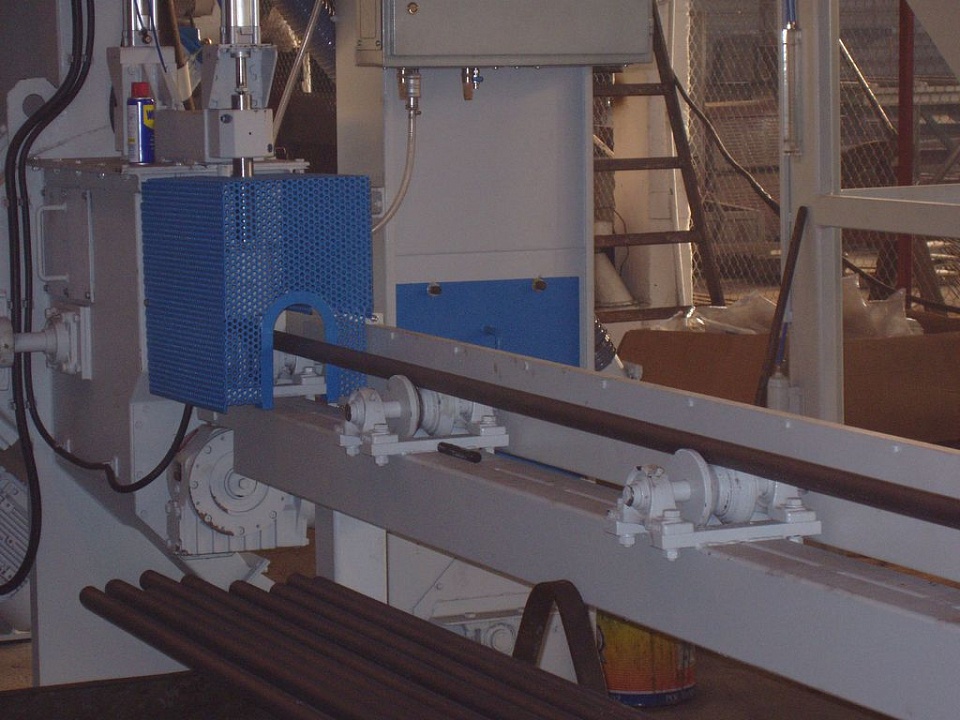

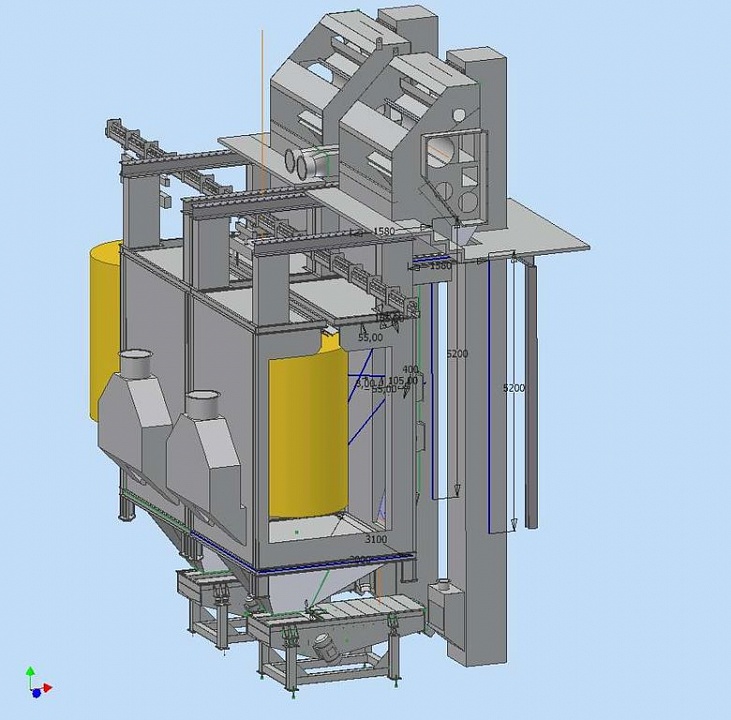

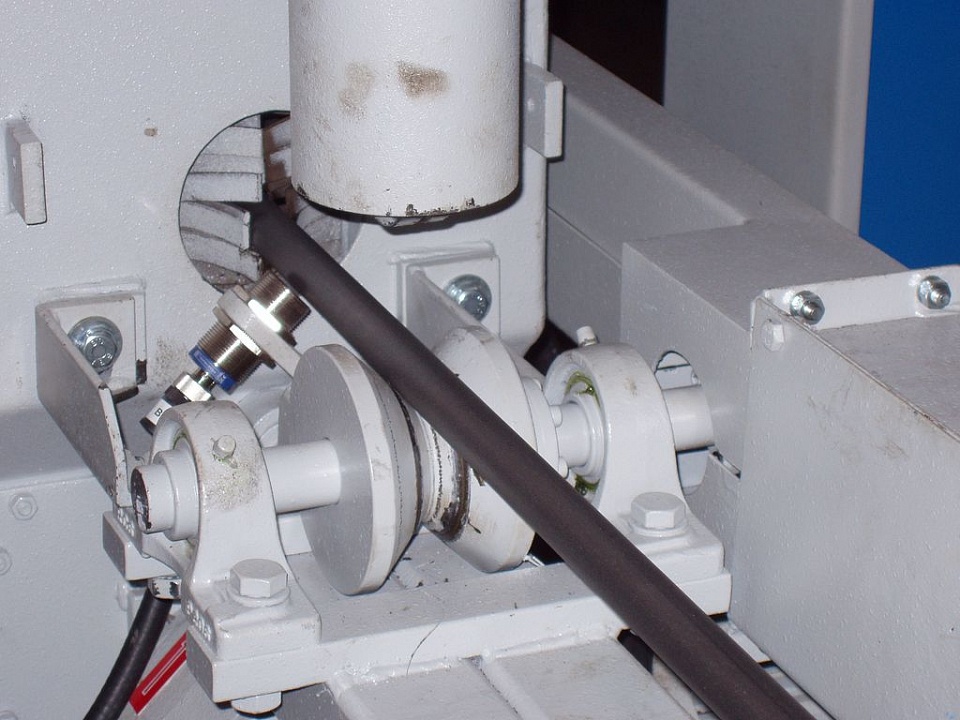

“PIP” series shotblasting machines are purpose-made shotblasting machines that are designed to blast pipes of various diameters and lengths at various transport speeds.

Pipes are loaded on an input roller conveyor with conical rollers or discs if pipes of larger diameters are involved. Rollers are mounted at a suitable angle, which enables simultaneous translation and rotation of a pipe during transport. Hence, pipes are transported through the machine’s tunnel part, on the brim of which turbines are placed that blast pipes along the entire outer surface. With larger diameters of pipes, turbines are built in on the bottom part of the shotblasting machine (under the pipe), so that the distance between turbines and blasted surface remains the same regardless of a pipe’s diameter. Work pieces then go on through the chamber, finally reaching the output roller conveyor.

In addition to standard machines, we also offer other machines of various sizes according to customer requirements.

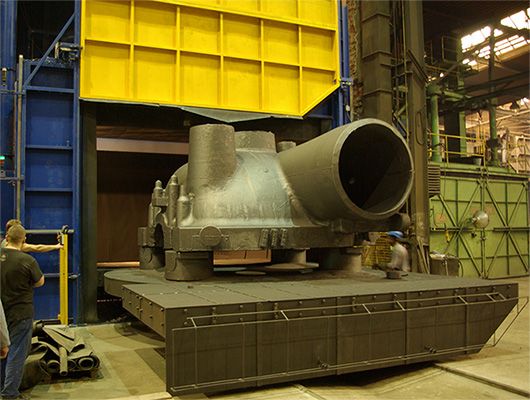

Shotblasting chambers type «KOM»

“KOM” type shotblasting chambers are designed for manual or automatic compressed air shotblasting of various work pieces, such as welded pieces, castings, forgings, railway wagons, containers, etc.

Work pieces are blasted in the chamber using compressed air that directs the blasting agent toward work pieces via a blasting nozzle. Then, a mixture of the blasting agent and residue falls into a trough, from where it is transported automatically to the elevator and air separator using scrapers and a transverse rotating worm. There, the blasting medium is purified, and after this it falls into a collection silo, ready to be used again. The shotblasting agent may be steel shot (round or granule), corundum, glass beads, etc.

In addition to standard machines, we also offer other machines of various sizes according to customer requirements.

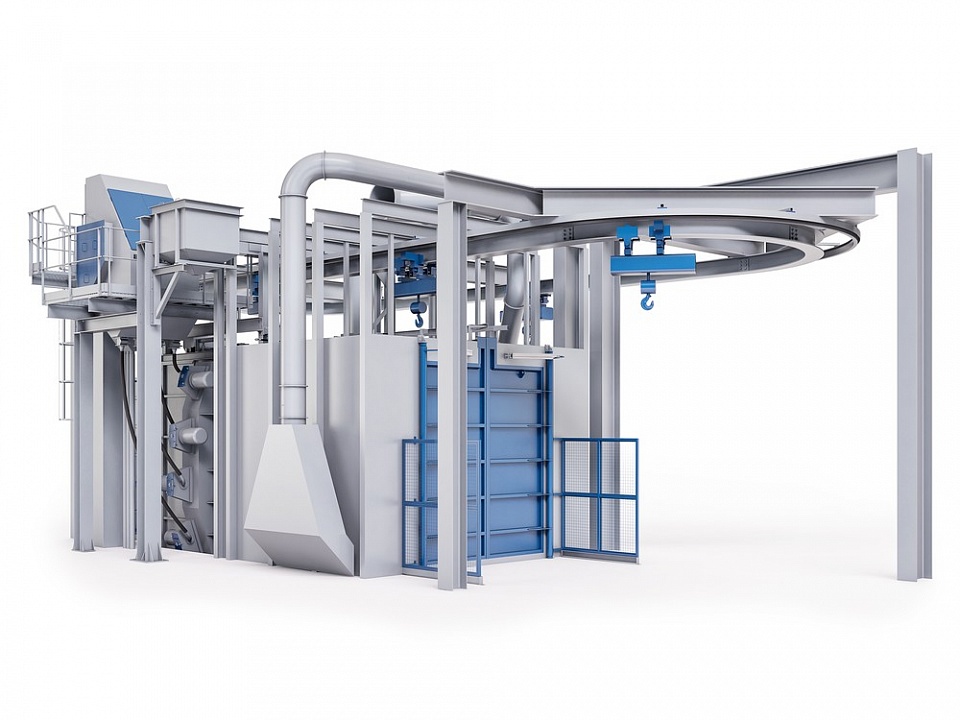

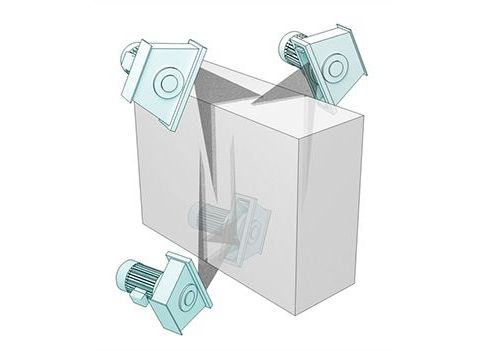

Tunnel overhead rail shotblasting machines type «TOR»

"TOR" type shotblasting machines are designed for blasting welded constructions, beams, and profiles of different shapes and dimensions. They are especially suitable for shot blasting work pieces of larger lengths. They can operate individually with their own rail or be integrated into an existing transport system. They can also integrate with paint application lines and drying chambers.

Work pieces are hung on hooks on the overhead transporter that transports work pieces through the tunnel part of the machine. On the lateral sides of the tunnel’s shotblasting part, turbines are carefully placed which provide the optimum coating and cleaning of a work piece, despite the fact that the work piece is not rotated in the shot blasting process under a jet of steel shot coming from the turbines. Work pieces pass on through the blow-off chamber in order for the shot blasting agent to be removed from exposed surfaces, finally exiting the machine.

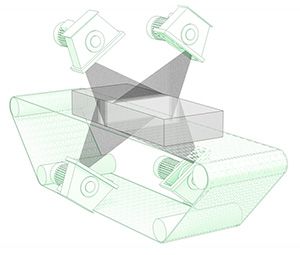

Turntable shotblasting machines type «T»

Type "T" shotblasting machines are universal shotblasting machines that may be used for blasting a wide variety of work pieces, such as welded constructions, castings, forgings, etc. A carefully planned position of turbines provides the optimum efficiency and uniformly cleaned surface of all sorts of work pieces, irrespective of their shape and size.

Work pieces are spread out on a turntable, individually or alongside each other, so that the jet captures them on their lateral sides also. During the blasting procedure, the table rotates in the shotblasting chamber, providing the optimum cleaning of work pieces.

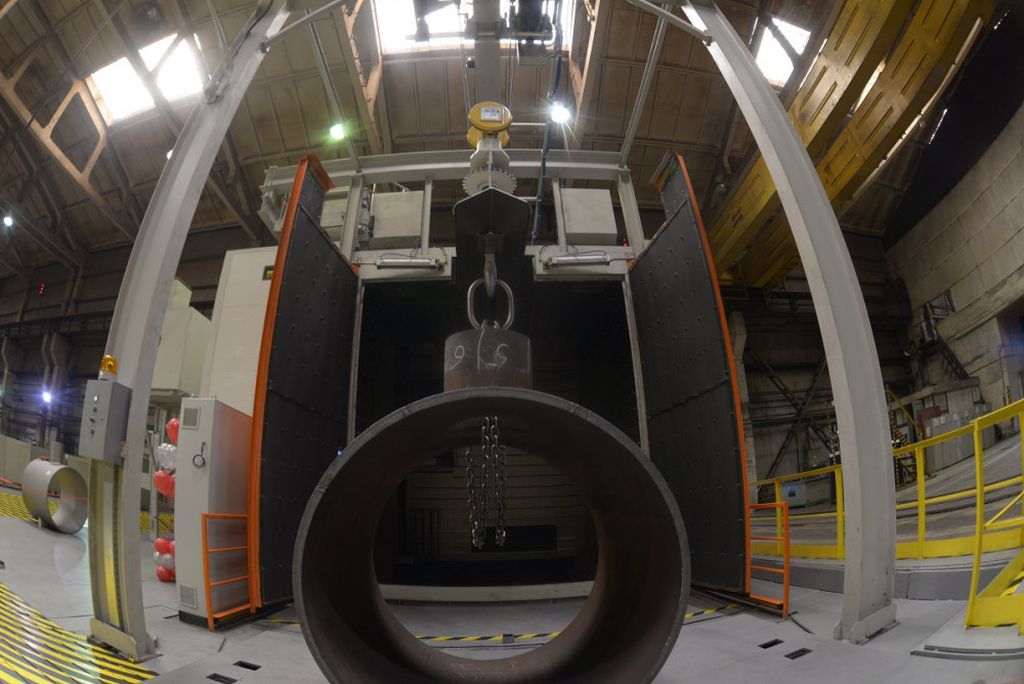

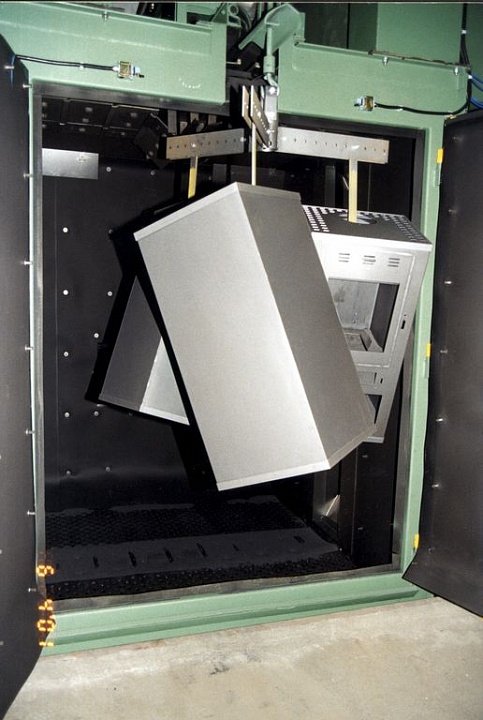

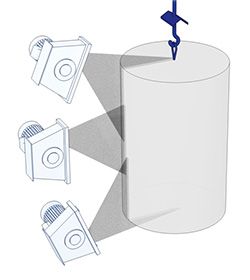

Hook shotblasting machines type «H»

“H” series shotblasting machines are designed to blast castings, welded pieces, forgings, etc. They are especially suitable for blasting sensitive pieces that may not strike one another during a shotblasting procedure. They operate on the tact principle with a setting of shotblasting time.

Work pieces are hung individually or in clusters onto a rotating hook that is fixed on a trolley on the transport rail. Transport rails may be produced in a variety of shapes and load capacities. The transport of work pieces to the door of the machine is carried out with a trolley on the transport rail, whereby the trolley may be manually or power driven. From here on, the movement of the trolley into the machine is automatic. During shotblasting, work pieces on the rotating hook spin in turbine jets, thus achieving uniform blasting of all surfaces. After the shotblasting cycle is concluded, the trolley containing work pieces is automatically transported from the machine.

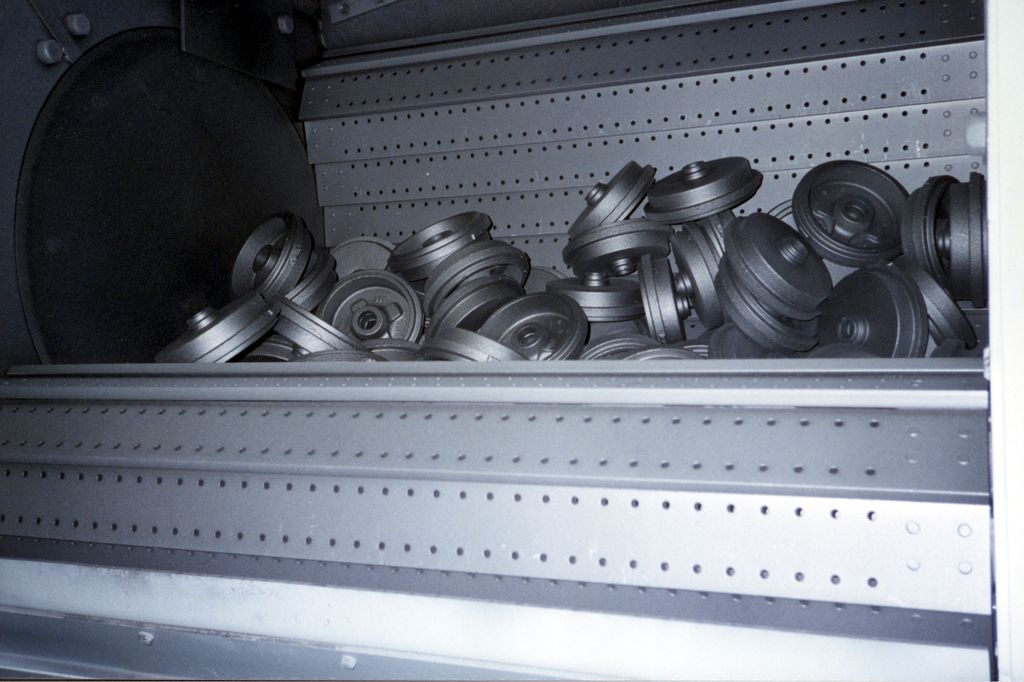

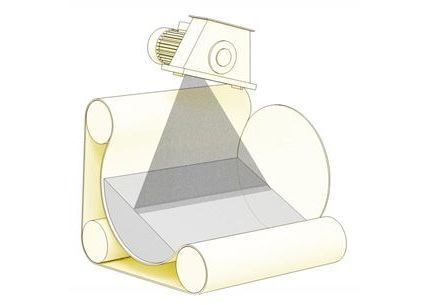

Tumble belt shotblasting machines type «B»

“B” series shotblasting machines are designed for blasting products of mass production as well as those of minor series. Primarily, these machines are used for blasting grey cast iron, nodular cast iron, steel castings, and also aluminium castings, precise castings, forgings, and for deburring metal and non-metal products. Shotblasting machines of “B” series are produced in two basic variants, namely with a runner belt (R) and a steel belt (S). Shotblasting machines of “B” type are called tumble belt because of the special shape of the belt that forms a loop in the shape of a tumble belt, whereto work pieces are loaded. Work pieces may be loaded into the machine manually or automatically with a skip in larger machines. During shotblasting, work pieces tumble continually in the loop formed by the belt under the jet of steel shot that is thrown by a turbine. After the blasting cycle is concluded, the belt turns in the opposite direction and work pieces are shot out of the machine.

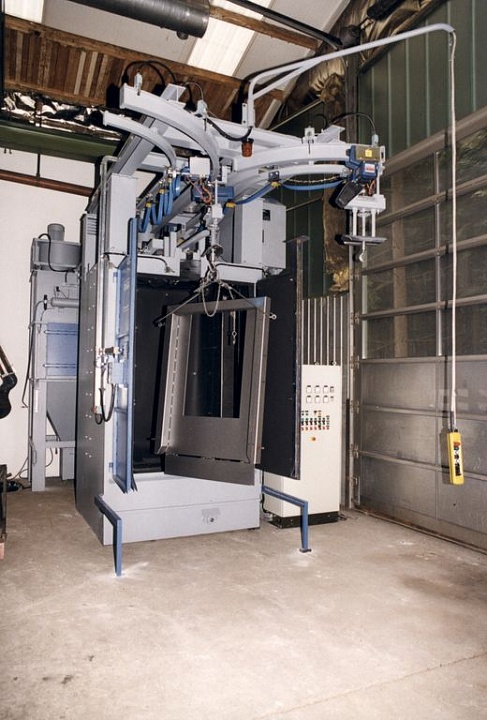

Сontinuous hook shotblasting machines type «CH»

“CH” series shotblasting machines are designed to blast castings, welded parts, forgings, etc. Work pieces are hung individually or in clusters onto rotating hooks that are fixed on trolleys on the transport rail. The transport rail may be produced in different lengths and with a different number of trolleys.

At the beginning of a cycle, a cluster is moved into the machine, the door closes, and shot blasting commences

During shotblasting, work pieces on rotating hooks are spun in turbine jets, thus achieving uniform blasting of all surfaces. At the end of the cycle, the door opens, the blasted cluster is moved out of the machine, and on the other side a new cluster is moved into the machine.

“CH” series machines are especially suitable for places with high productivity due to its small amount of dead time.

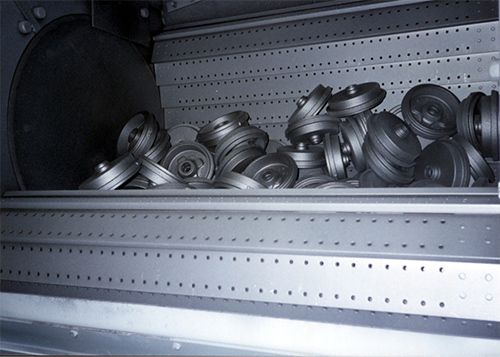

Mesh conveyor shotblasting machines type «MC»

“MC” series shotblasting machines are continuous flow shotblasting machines that are designed for continuous blasting of thin-walled and shock-sensitive castings. A larger number of turbines provides optimum efficiency and uniform cleaning of work pieces, therefore, this type of machines are also suited for shotblasting geometrically more demanding pieces, such as welded constructions, castings, etc.

Work pieces are loaded at the machine’s input onto a special conveyor mesh, made of high quality wear-resistant wire, which transports pieces through the tunnel part of the machine. On the outer brim of the blasting part of the tunnel, there are turbines that are positioned horizontally and vertically at a carefully planned angle, thus allowing optimum cleaning of work pieces from all sides. Work pieces travel on through the chamber for blowing the blasting agent off exposed surfaces, finally reaching the machine’s output.

Сharacteristics:

- “MC” series shotblasting machines are designed for continuous blasting of pieces that may not strike one another during a shotblasting procedure

- “MC” series machines enable continuous regulation of the operating speed and, if required, also the regulation of steel shot flow

- Shotblasting is turned on automatically, when work pieces travel under the turbines

- All machines are by standard equipped with a blow-off fan for removing steel shot from exposed surfaces of work pieces

- There is a selection of machines available with different sizes of work space and with numerous optional accessories which allow us to adjust our machines to the needs of even the most demanding customer.

Catalogs and documents

-

010_STEM_дробеметное оборудование Download .pdf/ 7.08 Mb